Abstract

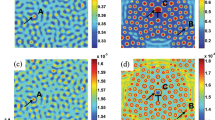

The interaction between dislocation and solute atoms during uniaxial tensile-loading deformation was simulated based on molecular dynamics. It is proved from the microscopic view (atomic level) that the essence of Portevin–Le Chatelier (PLC) effect originates from the influence of the solute atmosphere on the dislocation motion. The formation of the solute atmosphere is caused by lattice distortion. The lattice distortion increases the energy of the system, which promote the spontaneous diffusion of solute atoms through vacancies to the vicinity of edge dislocations to reduce the energy of the system. The simulation results show that higher solute atom concentration, lower strain rate, and temperature make the PLC effect more significant.

Similar content being viewed by others

References

W. Wen, Y.M. Zhao, and J.G. Morris, The Effect of Mg Precipitation on the Mechanical Properties of 5xxx Aluminum Alloys, Mater. Sci. Eng. A, 2005, 392(1), p 136–144.

D. Zhemchuzhnikova, M. Lebyodkin, D. Yuzbekova, T. Lebedkina, A. Mogucheva, and R. Kaibyshev, Interrelation Between the Portevin Le–Chatelier Effect and Necking in AlMg Alloys, Int. J. Plast., 2018, 110, p 95–109.

C.Y. Cui, R. Zhang, Y.Z. Zhou, and X.F. Sun, Portevin–Le Châtelier Effect in Wrought Ni-Based Superalloys: Experiments and Mechanisms, J. Mater. Sci. Technol., 2020, 51, p 16–31.

C.L. Mao, C.X. Liu, L.M. Yu, H.J. Li, and Y.C. Liu, The Correlation Among Microstructural Parameter and Dynamic Strain Aging (DSA) in Influencing the Mechanical Properties of a Reduced Activated Ferritic-Martensitic (RAFM) Steel, Mater. Sci. Eng. A, 2019, 732, p 90–98.

Z.T. Bai and Y. Fan, Abnormal Strain Rate Sensitivity Driven by A Unit Dislocation-Obstacle Interaction in bcc Fe, Phys. Rev. Lett., 2018, 120(12), p 125504.

J. Xu, C.M. Cao, P. Gu, and L.M. Peng, Microstructures, Tensile Properties and Serrated Flow of AlxCrMnFeCoNi High Entropy Alloys, Trans. Nonferrous Met. Soc. China, 2020, 30(3), p 746–755.

J.B. Xu, B. Holmedal, O.S. Hopperstad, T. Mánik, and K. Marthinsen, Dynamic Strain Ageing in an AlMg Alloy at Different Strain Rates and Temperatures: Experiments and Constitutive Modelling, Int. J. Plast., 2022, 151, p 103215.

H. Dierke, F. Krawehl, S. Graff, S. Forest, J. Šachl, and H. Neuhäuser, Portevin–LeChatelier Effect in Al-Mg Alloys: Influence of Obstacles-Experiments and Modelling, Comput. Mater. Sci., 2007, 39(1), p 106–112.

L.P. Kubin, C. Fressengeas, and G. Ananthakrishna, Collective behaviour of dislocations in plasticity. In: Dislocations in solids, F.R.N. Nabarro and M.S. Duesbery, Ed., vol. 11 (Elsevier, 2002), pp. 101–192

Q. Hu, Q. Zhang, S. Fu, P. Cao, and M. Gong, Influence of Precipitation on the Portevin–Le Chatelier Effect in Al-Mg Alloys, Theor. Appl. Mech. Lett., 2011, 1(1), p 011007.

C. Schwink and A. Nortmann, The Present Experimental Knowledge of Dynamic Strain Ageing in Binary fcc Solid Solutions, Mater. Sci. Eng. A, 1997, 234, p 1–7.

J.Z. Chen, L. Zhen, L.W. Fan, S.J. Yang, S.L. Dai, and W.Z. Shao, Portevin–Le Chatelier Effect in Al-Zn-Mg-Cu-Zr Aluminum Alloy, Trans. Nonferrous Met. Soc. China, 2009, 19(5), p 1071–1075.

P. Hähner, On the Critical Conditions of the Portevin–Le Chatelier Effect, Acta Mater., 1997, 45(9), p 3695–3707.

P. Hähner, A. Ziegenbein, E. Rizzi, and H. Neuhäuser, Spatiotemporal Analysis of Portevin–Le Châtelier Deformation Bands: Theory, Simulation, and Experiment, Phys. Rev. B, 2002, 65(13), p 134109.

F.B. Klose, A. Ziegenbein, F. Hagemann, H. Neuhäuser, P. Hähner, M. Abbadi, and A. Zeghloul, Analysis of Portevin–le Chatelier Serrations of Type Bin Al-Mg, Mater. Sci. Eng. A, 2004, 369(1–2), p 76–81.

S.R. Zhang, P.G. Mccormick, and Y. Estrin, The Morphology of Portevin–Le Chatelier Bands: Finite Element Simulation for Al-Mg-Si, Acta Mater., 2001, 49(6), p 1087–1094.

G. Lasko, P. Hähner, and S. Schmauder, Finite Element Simulation of the Portevin–Le Chatelier Effect, Modell. Simul. Mater. Sci. Eng., 2005, 13(5), p 645.

P. Hähner and E. Rizzi, On the Kinematics of Portevin–Le Chatelier Bands: Theoretical and Numerical Modelling, Acta Mater., 2003, 51(12), p 3385–3397.

E. Rizzi and P. Hähner, On the Portevin–Le Chatelier Effect: Theoretical Modeling and Numerical Results, Int. J. Plast., 2004, 20(1), p 121–165.

P.G. Mccormick and C.P. Ling, Numerical Modelling of the Portevin-Le Chatelier Effect, Acta Metall., 1995, 43(5), p 1969–1977.

S. Kok, M.S. Bharathi, A.J. Beaudoin, C. Fressengeas, G. Ananthakrishna, L.P. Kubin, and M. Lebyodkin, Spatial Coupling in Jerky Flow Using Polycrystal Plasticity, Acta Mater., 2003, 51(13), p 3651–3662.

X.J. Nie, H. Zhang, H.H. Zhu, Z.H. Hu, Y. Qi, and X.Y. Zeng, On the Role of Zr Content Into Portevin-Le Chatelier (PLC) Effect of Selective Laser Melted High Strength Al-Cu-Mg-Mn Alloy, Mater. Lett., 2019, 248, p 5–7.

A.O. Berk and E. Mert, Investigation of Portevin-Le Chatelier Bands in 5754 Aluminum Alloy under Various Strain Paths, Procedia Struct. Integr., 2019, 21, p 120–129.

P. Zhang, A.L. Song, Y.X. Fang, X.J. Yue, Y.Q. Wang, and X. Yu, A Study on the Dynamic Mechanical Behavior and Microtexture of 6082 Aluminum Alloy Under Different Direction, Vacuum, 2020, 173, p 109119.

E.B. Tadmor, R. Phillips, and M. Ortizc, Hierarchical Modeling in the Mechanics of Materials, Int. J. Solids Struct., 2000, 37(1–2), p 379–389.

T.S. Gates, G.M. Odegard, S.J.V. Frankland, and T.C. Clancy, Computational Materials: Multi-Scale Modeling and Simulation of Nanostructured Materials, Compos. Sci. Technol., 2005, 65(15–16), p 2416–2434.

S. Bross, P. Häahner, and E.A. Steck, Mesoscopic Simulations of Dislocation Motion in Dynamic Strain Ageing Alloys, Comput. Mater. Sci., 2003, 26, p 46–55.

Y. Qi, X. Chen, and M. Feng, Molecular Dynamics-Based Analysis of the Effect of Voids and HCP-Phase Inclusion on Deformation of Single-Crystal CoCrFeMnNi High-Entropy Alloy, Mater. Sci. Eng. A, 2020, 791, p 139444.

Z.N. Wang, J. Li, Q.H. Fang, B. Liu, and L.C. Zhang, Investigation Into Nanoscratching Mechanical Response of AlCrCuFeNi High-Entropy Alloys Using Atomic Simulations, Appl. Surf. Sci., 2017, 416, p 470–481.

M.J. Pu, Q. He, and J.Q. Zhou, Molecular Dynamic Study on the Deformation Mechanism Based on Strain Rate, Solute Atomic Concentration and Temperature in Dualphase Equiaxial Nanocrystalline AgCu Alloy, J. Alloys Compd., 2019, 795, p 241–253.

A. Mahata and K. Sikdar, Molecular Dynamics Simulation of Nanometer Scale Mechanical Properties of Hexagonal Mg-Li Alloy, J. Magnes. Alloys, 2016, 4(1), p 36–43.

S. Plimpton, Fast Parallel Algorithms for Short-Range Molecular Dynamics, J. Comput. Phys., 1995, 117(1), p 1–19.

X.Y. Liu and J.B. Adams, Grain-Boundary Segregation in Al-10%Mg Alloys at Hot Working Temperatures, Acta Mater., 1998, 46(10), p 3467–3476.

A. Stukowski, Visualization and Analysis of Atomistic Simulation Data with OVITO–the Open Visualization Tool, Modelling Simul, Mater. Sci. Eng., 2009, 18(1), p 015012.

A. Stukowski, V.V. Bulatov, and A. Arsenlis, Automated Identification and Indexing of Dislocations in Crystal Interfaces, Modell, Simul. Mater. Sci. Eng., 2012, 20(8), p 085007.

S. Heredia-Avalos, C.D. Denton, J.C. Moreno-Marín, E. Martinez, and M.J. Caturl, Collision Cascade Effects Near an Edge Dislocation Dipole in Alpha-Fe: Induced Dislocation Mobility and Enhanced Defect Clustering, J. Nucl. Mater., 2021, 543, p 152459.

X. Sauvage, N. Enikeev, R. Valiev, Y. Nasedkina, and M. Murashkin, Atomic-Scale Analysis of the Segregation and Precipitation Mechanisms in A Severely Deformed Al-Mg Alloy, Acta Mater., 2014, 72, p 125–136.

F.B. Klose and F. Hagemann, Investigation of the Portevin–Le Châtelier Effect in Al-3wt.%Mg Alloys by Strain-Rate and Stress-Rate Controlled Tensile Tests, Mater. Sci. Eng. A, 2001, 387, p 93–97.

M.C. Cai, L.S. Niu, T. Yu, H.J. Shi, and X.F. Ma, Strain Rate and Temperature Effects on the Critical Strain for Portevin–Le Chatelier Effect, Mater. Sci. Eng. A, 2010, 527(20), p 5175–5180.

C. Brandl, P.M. Derlet, and H. Van Swygenhoven, Strain Rates in Molecular Dynamics Simulations of Nanocrystalline Metals, Philosoph. Mag., 2009, 89(34–36), p 3465–3475.

D. Wang, X. He, Y. Dou, S. Wu, L. Jia, H. Cao, and W. Yang, Effect of Edge Dislocation on Solute-Enriched Clusters in Reactor Pressure Vessel Steel, Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms, 2019, 451, p 55–60.

J. Schiotz, T. Leffers, and B.N. Singh, Dislocation Nucleation and Vacancy Formation During High-Speed Deformation of fcc Metals, Phil. Mag. Lett., 2001, 81(5), p 301–309.

H. Flor and H. Neuhauser, Quantitative Analysis of Stress Relaxation in Cu-30% Zn Single Crystals: Variation of Obstacle Strength and Athermal Stress, Acta Metall., 1980, 28(7), p 939–948.

J. Wang, L.M. Yu, C. Li, Y. Huang, H.J. Li, and Y.C. Liu, Effect of Different Temperatures on He Atoms Behavior in α-Fe with and without Dislocations, Acta Metall. Sin., 2019, 55(2), p 274–280.

A.H. Cottrell and B.A. Bilby, Dislocation Theory of Yielding and Strain Ageing of Iron, Proc. Phys. Soc. Sect. A, 1949, 62, p 49.

K.P. Peng, W.Z. Chen, and K.W. Qian, Study on Dynamic Strain Aging Phenomenon of 3004 Aluminum Alloy, Mater. Sci. Eng. A, 2006, 415(12), p 53–58.

W. Wen and J.G. Morris, The Effect of Cold Rolling and Annealing on the Serrated Yielding Phenomenon of AA5182 Aluminum Alloy, Mater. Sci. Eng. A, 2004, 373(1–2), p 204–216.

R. Zhang, C.G. Tian, C.Y. Cui, Y.Z. Zhou, and X.F. Sun, Portevin–Le Châtelier Effect in a Wrought Ni-Co Based Superalloy, J. Alloys Compd., 2020, 818, p 152863.

H. Dierke, F. Krawehl, S. Graff, S. Forest, J. Šachl, and H. Neuhäuser, Portevin-LeChatelier Effect in Al-Mg Alloys: Influence of Obstacles-Experiments and Modelling, Comput. Mater. Sci., 2007, 39(1), p 106–112.

R.S. Fertig and S.P. Baker, Dislocation Dynamics Simulations of Dislocation Interactions and Stresses in Thin Films, Acta Mater., 2010, 58(15), p 5206–5218.

Acknowledgments

This project is supported by National Natural Science Foundation of China for National Major Scientific Research Equipment (Grant No. 52127808).

Funding

This project is supported by Natural Science Foundation of Hebei Province, China (Grant No. E2019203005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Luo, J., Xue, H., Chu, R. et al. Molecular Dynamics Simulation of Portevin–Le Chatelier Effect in Al-Mg Alloys: Effects of Solute Concentration, Temperature, and Tensile Rate. J. of Materi Eng and Perform 32, 9884–9891 (2023). https://doi.org/10.1007/s11665-023-07825-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07825-5