Abstract

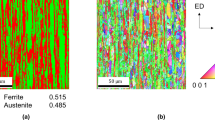

Expansion tube technology is important in supporting the oil drilling industry. The 2205 duplex stainless steel exhibits excellent corrosion resistance, offers superior mechanical properties, and demonstrates good expansion material in the downhole. During the expansion process, the deformation mechanism and grain orientation of 2205 duplex stainless steel were analyzed using TEM and EBSD. The stress state soft coefficient was used to compare the expansion and tensile states, which revealed that the expansion stress state was not conducive to plastic deformation. Further, microstructure analysis showed that α phase in 2205 duplex stainless steel consists of a body-centered cubic structure, its deformation mechanism was dislocation slip, and dislocation density was low. The γ phase consists of a face-centered cubic structure, and its deformation mechanism was twinning-induced plasticity, which is the major contribution region of plastic deformation. The comparison of the Taylor factor of the two phases showed that the γ phase is the “soft phase” and the α phase is the “hard phase,” and the deformation of the γ phase preferentially occurs during the expansion process. The grain orientation of the α phase after the expansion was <110>, while the grain orientation of the γ phase after the expansion was <111>.

Similar content being viewed by others

References

G.Q. Qi, Z. Yang, F.S. Shangguan, L.N. Yang, Q. Bai, and G. Wu, Research Progress and Engineering Application of Expandable Tube Technology, Oil Field Equip., 2012, 41(12), p 72–76. ((in Chinese))

Y.X. Wang, X.G. Liu, and Q.C. Zhou, Study on Expansion Tube Technology And its Application in Oil Field, Inner Mong. Petrochem. Ind., 2013, 39(24), p 112–113. (in Chinese)

W.Z. Shen, C.F. Li, Y. Yang, W.X. Yang, and X. Jin, Development Status of Expansion Pipe Steel, Hot work. Technol., 2015, 44(12), p 27–31. (in Chinese)

R.P. Xu, J. Liu, Y.X. Zhang, Y.R. Chen, and W.X. Liu, Standard for the Design of Petroleum Expansion Pipe Materials, China Pet. Mach., 2005, 33(11), p 35–38. (in Chinese)

W.Y. Zhang and S.Z. Hou, Application Progress of Duplex Stainless Steel at Home and Abroad, Equip. Mach., 2015, 03, p 62–66. (in Chinese)

W. Gao, J.M. Luo, and J.J. Yang, Research Progress and Application of Duplex Stainless Steel, Ordnance Mater. Sci. and Eng., 2005, 28(03), p 61–64. (in Chinese)

W.J. Yang, W.J. Meng, and X.B. Dai, Microstructure and Dry Friction of 2205 Dual-Phase Steel during Solution Precipitation, Shock Vib., 2021, 07, p 1–9.

X.J. Meng, F.Y. Meng, W.W. Song, X.Q. Mao, M.F. Zhao, Z.L. Chang, H.Y. Zang, and T. Zhang, Effect of Two Kinds of Heat Treatment on Corrosion Behavior of 2205 Duplex Stainless Steel, Corros. and Prot., 2012, 33(07), p 563–566. (in Chinese)

S.S. Xing, H.Y. Qi, and C.B. Zheng, Effect of Solution Treatment on Microstructure and Passivation Film Characteristics of 2205 Duplex Stainless Steel, Heat Treat. of Met., 2020, 45(3), p 146–150. (in Chinese)

H. Nima, L. Carina, H.S. Chen, Z.B. Chen, Q. Liu, X.P. Li, R. Gregory, X.Z. Liao, R. Simon, and P. Sophie, Evolution of Microstructure And Mechanical Properties In 2205 Duplex Stainless Steels During Additive Manufacturing And Heat Treatment, Mater. Sci. and Eng. A, 2022, 835, p 142695.

E.F. Oluwasegun, B.M. Edwin, R.O. Samuel, and A.O. Peter, Influence of Solution Heat Treatment on Microstructure and Mechanical Properties of a Hot-Rolled 2205 Duplex Stainless Steel, J. Mater. Eng. Perform., 2021, 30(10), p 7185–7194.

R.J. Zhang, F.F. Gen, Z.L. Liu, and M. Wu, Effect of Heat Treatment Temperature ON Microstructure and Microhardness of Super Super Duplex Stainless Steel, Cast. Equip. Technol., 2019, 06, p 25–28. (in Chinese)

S. Zhao, K.X. Liao, C. Wu, X.Y. Liu, J.H. Leng, and M. Qin, Research Progress on Stress Corrosion Behavior and Protection Technology of Duplex Stainless Steel, Surf. Technol., 2022, 51(08), p 123–134. (in Chinese)

S.P. Qu, B.Z. Cheng, L.H. Dong, Y.S. Yin, and L.J. Yang, Corrosion Behavior of 2205 Steel in Simulated Deep-Sea Hydrothermal Zone, Acta Metal. Sin., 2018, 54(08), p 1094–1104. (in Chinese)

J. Liao and J.W. Liu, Effect of Aging Resolution Treatment on Mechanical and Corrosion Resistance of 2205 Duplex Stainless Steel, Chem. Equip. Pipeline, 2019, 56(04), p 73–76. (in Chinese)

J.G. Odhiambo, W.G. Li, Z. Li, Y.T. Zhao, and C.L. Li, Corrosion Behaviour of 2205 Duplex Stainless Steel in Marine Conditions Containing Erythrobacter Pelagi Bacteria, Mater. Chem. Phys., 2020, 239, p 122010.

N. Li, S. Hao, L. Chen, C. Peng, M. Jin, and C.Y. Song, Tensile and Cold Rolling Deformation Behavior of TriP-Type Duplex Stainless Steel, J. Plast. Eng., 2021, 28(11), p 102–108. (in Chinese)

X. Zhang, P. Wang, D.Z. Li, and Y.Y. Li, Multi-Scale Study on The Heterogeneous Deformation Behavior in Duplex Stainless Steel, J. Mater. Sci. Technol., 2021, 72, p 180–188.

A.M. Yuan, J.K. Li, X.D. Gao, and X.P. Ren, Effect of Cold Rolling and Aging Process On σ Phase Precipitation of 2205 Duplex Stainless Steel, Heat Treat. of Met., 2021, 46(10), p 26–30. (in Chinese)

J. Wang and Q. Zhang, Effect of Aging Process on Microstructure and Mechanical Properties of 2205 Duplex Stainless Steel, Mech. Res. Appl., 2011, 24(03), p 65–67. (in Chinese)

Y.J. Zhang and M.R. Lei, The Theoretical Model of Expansion Force of Solid Expansion Tube is Simplified, Mach. Tool Hydraul., 2019, 47(07), p 150–154. (in Chinese)

D.L. Shu, Mechanical properties of engineering materials, HeFei University of Technology, 2017, p 43

H.J. Dong, Comparative study on microscopic evolution of cyclic deformation of austenite and ferrite, Master Thesis, Dalian University of Technology, 2019

X. Zhang, Study on stress - strain distribution and microdeformation mechanism in duplex stainless steel, Doctoral thesis, University of Science and Technology of China, 2020

X.Z. Li, Study on two-phase deformation and slip transfer mechanism at interface in 2205 duplex stainless Steel based on EBSD and SEM-DIC, Master Thesis, Southwest Jiaotong University, 2020

A. Dumay, J.P. Chateau, S. Allain, S. Migot, and O. Bouaziz, Influence of Addition Elements on the Stacking-Fault Energy and Mechanical Properties of an Austenitic Fe-Mn-C Steel, Mater. Sci. and Eng. A, 2008, 483, p 184–187.

S. Allain, J.P. Chateau, O. Bouaziz, S. Migot, and N. Guelton, Correlations Between the Calculated Stacking Fault Energy and the Plasticity Mechanisms in Fe-Mn-C Alloys, Mater. Sci. Eng., 2004, 387, p 158–162.

X.M. Chen, Y.H. Wang, and T.S. Wang, Review on Factors Affecting Mechanical Properties of High Manganese Steel, Hot Work. Technol., 2022, 04, p 1–7. (in Chinese)

M. Koyama, Twinning-Induced Plasticity (TWIP) Steel, Ref. Modul. in Mater. Sci. Mater. Eng., 2020

D.Z. Li, Y.H. Wei, C.Y. Liu, L.F. Hou, D.F. Liu, X.Z. Jin, Effects of High Strain Rate on Properties and Microstructure Evolution of TWIP Steel Subjected to Impact Loading, J. of Iron and Steel Res. Int., 2010, 17(06), p 67–73

C.Y. Liu, K.H. Song, W. Wu, P. Jiang, Y.F. Jiang, X.C. Xia, B. Liao, 2021 Microstructure analysis and crack nucleation in TWIP steel tube at expansive deformation, Mater. Res. Express 8(12)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, W., Song, K.H., Liu, C.Y. et al. Study on Special Deformation Mechanism of 2205 Duplex Stainless Steel During Expansion Test. J. of Materi Eng and Perform 32, 8625–8636 (2023). https://doi.org/10.1007/s11665-022-07767-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07767-4