Abstract

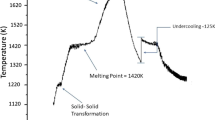

Rapid solidification with a high degree of undercooling is an important method for investigating the metastable solidification of metallic materials. In this paper, we study the microstructural evolution and applied performance characteristics of bulk Ni-5% Cu alloys with degrees of undercooling ranging from 53 to 380 K by a glass fluxing technique. The microstructure homogeneity increases, and the grain refinement increases with increasing degree of undercooling. The global microstructure transforms from a coarse dendrite microstructure into a refined equiaxed grain microstructure as the degree of undercooling increases. Additionally, EDS results illustrate that the segregation less solidification with a remarkable solute trapping effect is preferentially achieved under high undercooling conditions. The compressive yield strength, Vickers hardness and bending modulus of the bulk Ni-5% Cu alloy all increase with increasing melt undercooling. Moreover, the soft magnetic properties of the alloy are modulated when the degree of undercooling changes.

Similar content being viewed by others

Data Availability

The datasets generated and/or analyzed during this study are available from the author on reasonable request.

References

H.S. Lee, D.H. Kim, D.S. Kim, and K.B. Yoo, Microstructural Changes by Heat Treatment for Single Crystal Superalloy Exposed at High Temperature, J. Alloys Compd., 2013, 561, p 135–141.

H. Kasturi, T. Paul, S. Biswas, S.H. Alavi, and S.P. Harimkar, Sliding Wear Behavior of Spark-Plasma-Sintered Fe-Based Amorphous Alloy Coatings on Cu-Ni Alloy, J. Mater. Eng. Perform., 2018, 27, p 3629–3635.

J. Tang and X. Xue, Numerical Simulation of Multi-Grain Structure and Prediction of Microsegregation in Binary Ni-Cu Alloy Under Isothermal Conditions, Mater. Sci. Eng. A, 2009, 499, p 64–68.

L.F. Du, P. Zhang, J. Chen, and H.L. Du, Effects of Lateral Constraints on the Morphology Evolution and Solute Diffusion During Solidification in a Binary Alloy, Appl. Phys. A, 2017, 123(311), p 1–11.

X.H. Wu, G. Wang, L.Z. Zhao, D.C. Zeng, and Z.W. Liu, Phase Field Simulation of Dendrite Growth in Binary Ni-Cu Alloy Under the Applied Temperature Gradient, Comp. Mater. Sci., 2016, 117, p 286–293.

Y.W. Kim, Y.S. Chung, E. Choi, and T.H. Nam, Microstructure and Shape Memory Characteristics of Powder-Metallurgical-Processed Ti-Ni-Cu Alloys, Metall. Mater. Trans. A, 2012, 43A, p 2932–2937.

D. Liu, W.A. Miller, and K.T. Aust, Diffusion Induced Grain Boundary Migration in a Rapidly Solidified, Oxidized Ni-Cu Alloy, Scripta Metall., 1987, 21, p 643–647.

H.P. Wang, W.J. Yao, and B.B. Wei, Remarkable Solute Trapping Within Rapidly Growing Dendrites, Appl. Phys. Lett., 2006, 89(20), p 215502.

Y. Ruan, X.J. Wang, and S.Y. Chang, Two Hardening Mechanisms in High-Level Undercooled Al-Cu-Ge Alloys, Acta Mater., 2015, 91, p 183–191.

X. Li, A. Gagnoud, Y. Fautrelle, Z.M. Ren, R. Moreau, Y.D. Zhang, and C. Esling, Dendrite Fragmentation and Columnar-to-Equiaxed Transition During Directional Solidification at Lower Growth Speed Under a Strong Magnetic Field, Acta Mater., 2012, 60(8), p 3321–3332.

F. Liu, G. Yang, and X. Guo, Research of Grain Refinement in Undercooled DD3 Single Crystal Superalloy, Mater. Sci. Eng. A, 2001, 311(1–2), p 54–63.

N. Yan, Z.H. Wang, Y. Ruan, and B.B. Wei, Solute Redistribution and Micromechanical Properties of Rapidly Solidified Multicomponent Ni-Based Alloys, Sci. Chin., 2019, 62(3), p 472–477.

L.G. Cao, R.F. Cochrane, and A.M. Mullis, Lamella Structure Formation in Drop-Tube Processed Ni-25.3 at.% Si Alloy, J. Alloys Compd., 2015, 615(S1), p S599–S601.

N. Haque, R.F. Cochrane, and A.M. Mullis, Disorder-Order Morphologies in Drop-Tube Processed Ni3Ge: Dendritic and Seaweed Growth, J. Alloys Compd., 2017, 707, p 327–331.

O. Oloyede, T.D. Bigg, R.F. Cochrane, and A.M. Mullis, Microstructure Evolution and Mechanical Properties of Drop-Tube Processed, Rapidly Solidified Grey Cast Iron, Mater. Sci. Eng. A, 2016, 654, p 143–150.

S. Li, H.F. Wang, and F. Liu, Microstructure and Microtexture Evolution of Undercooled Ni-15% Cu Alloy, Trans. Nonferrous Met. Soc. Chin., 2013, 23, p 3265–3270.

E.G. Castle, A.M. Mullis, and R.F. Cochrane, Evidence for an Extended Transition in Growth Orientation and Novel Dendritic Seaweed Structures in Undercooled Cu-8.9wt.%Ni, J. Alloys Compd., 2014, 615, p S612–S615.

E.G. Castle, A.M. Mullis, and R.F. Cochrane, Evidence for an Extensive, Undercooling-Mediated Transition in Growth Orientation, and Novel Dendritic Seaweed Microstructures in Cu–8.9 wt.% Ni, Acta Mater., 2014, 66, p 378–387.

Y.K. An, X.L. Xu, L. Liang, Y.H. Zhao, and H. Hou, Microstructure Transformation and Grain Refinement During Non-Equilibrium Solidification of a Highly Undercooled Alloy System, J. Alloys Compd., 2021, 864, p 158821.

K. Ma, Y.H. Zhao, X.L. Xu, and H. Hou, The Effect of Undercooling on Growth Velocity and Microstructure of Ni95Cu5 Alloys, J. Cryst. Growth, 2019, 513, p 30–37.

P. Lv and H.P. Wang, Effects of Undercooling and Cooling Rate on Peritectic Phase Crystallization Within Ni-Zr Alloy Melt, Metall. Mater. Trans. B, 2018, 49B, p 499–507.

C.K. Deng, H.X. Jiang, J.Z. Zhao, J. He, and L. Zhao, Study on the Solidification of Ag-Ni Monotectic Alloy, Acta Metall. Sin., 2020, 56(2), p 212–219.

R. Ahmad, R.F. Cochrane, and A.M. Mullis, The Formation of Regular αNi-γ(Ni31Si12) Eutectic Structures from Undercooled Ni-25 at.% Si Melts, Intermetallics, 2012, 22, p 55–61.

T. Koseki and M.C. Flemings, Solidification of Undercooled Fe-Cr-Ni Alloys: Part III, Phase Select. Chill Cast., 1997, 28(11), p 2385–2395.

S.J. Chen, D.G. Howitt, and A.B. Harker, A Dynamical Bragg Equation for High-Order Laue Zone Reflections, Scanning, 2000, 22, p 157.

R.D. Li, X.S. Cao, Y.D. Qu, Y. Xie, R.X. Li, and C. Tian, Effect of Super High Pressure on Crystal Structure and Microstructure of ZA27 Alloy, Chin. J. Nonferrous Met., 2009, 19(9), p 1572.

N. Yan, L. Hu, Y. Ruan, W.L. Wang, and B.B. Wei, Liquid State Undercoolability and Crystal Growth Kinetics of Ternary Ni-Cu-Sn Alloys, Chin. Phys. Lett., 2016, 33(10), p 108103.

Z. Hussain, H. Jang, H.J. Choi, and B.S. Choi, Microstructure, Mechanical Behavior, and Thermal Conductivity of Three-Dimensionally Interconnected Hexagonal Boron Nitride - Reinforced Cu-Ni Composite, J. Mater. Eng. Perform., 2022, 31, p 2792–2800.

D. Goranova, G. Avdeev, and R. Rashkov, Electrodeposition and Characterization of Ni-Cu Alloys, Surf. Coat. Technol., 2014, 240, p 204–210.

G.J. Lee, J.H. Lee, D.J. Lee, K.I. Park, C.K. Jeong, J.J. Park, and M.K. Lee, Synthesis and Characterization of Carbon-Coated Cu-Ni Alloy Nanoparticles and Their Application in Conductive Films, Appl. Surf. Sci., 2021, 566, p 150672.

M. Negem and H. Nady, Electroplated Ni-Cu Nanocrystalline Alloys and Their Electrocatalytic Activity for Hydrogen Generation Using Alkaline Solutions, Int. J. Hydrog. Energy, 2017, 42(47), p 28386–28396.

H. Nady and M. Negem, Ni-Cu Nano-Crystalline Alloys for Efficient Electrochemical Hydrogen Production in Acid Water, RSC Adv., 2016, 6, p 51111–51119.

X.L. Xu, Y.H. Zhao, and H. Hou, Observation of Dendrite Growth Velocity and Microstructure Transition in Highly Undercooled Single Phase Alloys, Mater. Charact., 2019, 155, p 109793.

E.G. Castle, A.M. Mullis, and R.F. Cochrane, Mechanism Selection for Spontaneous Grain Refinement in Undercooled Metallic Melts, Acta Mater., 2014, 77, p 76–84.

A. Bagri, G. Weber, J.C. Stinville, W. Lenthe, T. Pollock, C. Woodward, and S. Ghosh, Microstructure and Property-Based Statistically Equivalent Representative Volume Elements for Polycrystalline Ni-Based Superalloys Containing Annealing Twins, Metall. Mater. Trans. A, 2018, 49, p 5727–5743.

T. Pinomaa and N. Provatas, Quantitative Phase Field Modeling of Solute Trapping and Continuous Growth Kinetics in Quasi-Rapid Solidification, Acta Mater., 2019, 168, p 167–177.

P.K. Galenko and D. Jou, Rapid Solidification as Non-Ergodic Phenomenon, Phys. Rep., 2019, 818, p 1–70.

G.D. Merz and T.Z. Kattamis, Mechanical Behavior of Cast Single Phase Alloys Solidified from Undercooled Melts, Metall. Trans. A, 1977, 8A, p 295–298.

C.Y. Zhang, Q.F. Wang, J.X. Rena, R.X. Li, M.Z. Wang, F.C. Zhang, and K.M. Sun, Effect of Martensitic Morphology on Mechanical Properties of an as-Quenched and Tempered 25CrMo48V Steel, Mater. Sci. Eng. A, 2012, 534, p 339–346.

O. Heczko, P. Svec, D. Janickovic, and K. Ullakko, Magnetic Properties of Ni-Mn-Ga Ribbon Prepared by Rapid Solidification, IEET. T Magn., 2002, 38(5), p 2841–2843.

R.H. Yu, S. Basu, Y. Zhang, A. Parvizi-Majidi, and John Q. Xiao, Pinning Effect of the Grain Boundaries on Magnetic Domain Wall in FeCo-Based Magnetic Alloys, J. Appl. Phys., 1999, 85(9), p 6655–6559.

S. Olvera, J. Sánchez-Marcos, F.J. Palomares, E. Salas, E.M. Arce, and P. Herrasti, Characterization and Corrosion Behaviour of CoNi Alloys Obtained by Mechanical Alloying, Mater. Charact., 2014, 93, p 79–86.

N. Hassan, I.A. Shah, M. Jelani, M. Naeem, S. Riaz, S. Naseem, F. Xu, and Z. Ullah, Effect of Ni-Mn Ratio on Structural, Martensitic and Magnetic Properties of Ni-Mn-Co-Ti Ferromagnetic Shape Memory Alloys, Mater. Res. Exp., 2018, 5(8), p 086102.

S. Tebbakh, A. Beniaiche, N. Fenineche, A. Azizi, G. Schmerber, and A. Dinia, Electrochemical Nucleation Behaviors and Properties of Electrodeposited Co-Ni Alloy Thin Films, Trans. Inst. Met. Finish., 2013, 91(1), p 17–22.

V. Vega, L. Gonzalez, J. Garcia, W.O. Rosa, D. Serantes, V.M. Prida, G. Badini, R. Varga, J.J. Sunol, and B. Hernando, Ni59.0Mn23.5In17.5 Heusler Alloy as the Core of Glass-Coated Microwires: Magnetic Properties and Magnetocaloric Effect, J. Appl. Phys., 2012, 112, p 033905.

J. Echigoya and R. Yue, Grain-Size Dependence of Coercive Force in Sputtered and Annealed Iron Films, J. Mater. Sci., 2005, 40(12), p 3209–3212.

D.S. Yao, S.H. Ge, X.Y. Zhou, and H.P. Zuo, Grain Size Dependence of Coercivity in Magnetic Metal-Insulator Nanogranular Films with Uniaxial Magnetic Anisotropy, J. Appl. Phys., 2010, 107(7), p 073902.

Acknowledgements

This work was financially supported by National Natural Science Foundation of China (Grant Nos, 51871186, 52074230 and U1904214). The analyses from the Analytical & Testing Center of Northwestern Polytechnical University are appreciated. We would like to thank the director of LMSS—Prof. B. Wei—for his consistent support.

Author information

Authors and Affiliations

Contributions

JZL: Conceptualization, methodology, data curation, investigation, writing-original draft, writing-review & editing. NY: Funding acquisition, project administration, investigation, supervision, writing – review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Jz., Yan, N. Microstructural Evolution and Applied Performance of a Highly Undercooled Bulk Ni-5% Cu Alloy. J. of Materi Eng and Perform 32, 7162–7172 (2023). https://doi.org/10.1007/s11665-022-07626-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07626-2