Abstract

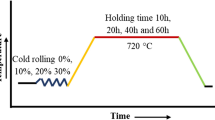

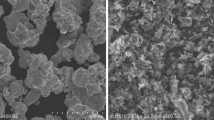

Variations in the microstructure of steel materials might change the alloy’s properties and characteristics and influence the performance of manufacturing processes. The literature on the materials characterization in this area has been limited to examining the effects of the spheroidization of microstructure in certain materials. Taking this into account, this study aims to assess the influence of the spheroidization rate on the microstructure and mechanical properties in a SAE 8640 steel subjected to different annealing cycles. Three different thermal cycles were tested, varying the time, temperature, and type parameters. The practical results of the annealing cycles were evaluated through optical microscopy, scanning electron microscopy, microhardness tests, and x-ray diffraction. Findings showed hardness reduction for all the cycles examined, particularly for Cycle III (isothermal annealing), whose reduction was approximately 98 Hv compared to the samples without heat treatment. The findings showed that hardness values below the average at 0.10 mm under the tested surfaces were observed in the three cycles examined, suggesting the occurrence of the decarburization process. A spheroidization rate of 79.93% was achieved in Cycle II (pendulum temperature behavior). The study’s findings make a positive contribution to the research that investigates the mapping of the metallurgical and mechanical aspects of spherical low-alloy and medium-carbon steels.

Similar content being viewed by others

References

E.D.R. Vieira, L.V. Biehl, J.L.B. Medeiros, V.M. Costa, and R.J. Macedo, Evaluation of the Characteristics of an AISI 1045 Steel Quenched in Different Concentration of Polymer Solutions of Polyvinylpyrrolidone, Sci. Rep., 2021, 11, p 1–8.

J.W. Seon et al., The Effect of a Non-Circular Drawing Sequence on Spheroidization of Medium Carbon Steel Wires, J. Mater. Process. Technol., 2016, 216, p 348356.

L.H.D. Santos, L. Schaeffer, and S.Q. Fortunato et al., Study of Full Annealing and Spheroidizing Heat Treatments in the ABNT 1045 Steel Cold Flow Stress Curves, Tecnologia Metalurgica de Materiais e Mineração, 2018, 15(1), p 75–79.

V. Alcántara et al., Spheroidizing in Steels: Processes, Mechanisms, Kinetic and Microstructure -A Review, IOSR J. Mech. Civ. Eng., 2021, 18, p 63–81.

A. Saha, D.K. Mondal, and J. Maity, An Alternate Approach to Accelerated Spheroidization in Steel by Cyclic Annealing, J. Mater. Eng. Perform., 2011, 20(1), p 114–119.

C. Prasad, P. Bhuian et al., Microstructure Engineering by Dispersing Nano-Spheroid Cementite in Ultrafine-Grained Ferrite and its Implications on Strength-Ductility Relationship in High Carbon Steel, Mater. Des., 2018, 139, p 324–335.

Z. Li et al., Microstructure of Hot Rolled 1.0C-1.5Cr Bearing Steel and Subsequent Spheroidization Annealing, Metall. Mater. Trans. A, 1987, 18A, p 1403–1414.

W. You et al., Materialometrical Approach of Predicting the Austenite Formation Temperatures, Mater. Sci. Eng. A, 2006, 419, p 276–282.

D. Zhenglin and S. Xianchong et al., Thermo-Metallurgical Simulation and Performance Evaluation of Hybrid Laser Arc Welding of Chromium-Molybdenum Steel, Mater. Des., 2021, 210, p 110029.

H. Zhao, J. Gao, J. Qi, Z. Tian, H. Chen, H. Zhang, and C. Wang, Modelling and Simulation of Isothermal and Continuous-Heating Surface Decarburization Behaviour of Fe-0.6C-1.8Si-0.8Mn Spring Steel, J. Mater. Res. Technol., 2021, 15, p 1076–10.

P.C. Hernandéz, J.E. Fonseca, and L.F. Dick, Development of Methodology for Evaluation of Spheroidized Steels, Tecnologia Metalúrgica de Materiais e Mineração, 2013, 6(3), p 158–61.

J.M. O’Brien and W.F. Hosford, Spheroidization Cycles for Medium Carbon Steels, Metall. Mater. Trans. A, 2002, 33(4), p 1255–1261.

I. Muda and D. P. Dunne, Effect of annealing cycle on drawability and microstructure of cold rolled steel sheet. in: IOP conference series: materials science and engineering, 2019, 547.

M. Çetin and Ç. Demirel, A Study on Abrasive Wear and Corrosion Behaviour of Boronized AISI 8640 CAST Steel, Eur. Int. J. Sci. Technol., 2018, 7(9), p 14–32.

J. Wei, Y. Zhou, J. Dong, X. He, and W. Ke, Effect of Cementite Spheroidization on Improving Corrosion Resistance of Pearlitic Steel Under Simulated Bottom Plate Environment of Cargo Oil Tank, Materialia, 2019, 6, p 100316.

Y. Yang, M.F. Yan, Y.X. Zhang, C.S. Zhang, and X.A. Wand, Self-Lubricating and Anti-Corrosion Amorphous Carbon/Fe3C Composite Coating on M50NiL Steel by Low Temperature Plasma Carburizing, Surf. Coat. Technol., 2016, 304, p 142–149.

L. Wei, K. Gao, and Q. Li, Corrosion of Low Alloy Steel Containing 0.5% Chromium in Supercriti-Cal CO2-Saturated Brine and Water-Saturated Supercritical CO2 Environments, Appl. Surf. Sci., 2018, 440, p 524–534.

R.C.L.M. Oliveira, L.V. Biehl, M.J.L. Braz, D. Ferreira Filho, and J.D. Souza, Análise Comparativa Entre A Têmpera e Partição Versus A Têmpera E Revenimento Para O Aço Sae 4340, Rev. Mater., 2019, 24, p 1–9.

Y. Su and L.J. Miao et al., Effect of Isothermal Quenching on Microstructure and Hardness of GCr15 Steel, J. Market. Res., 2021, 15, p 2820–2827.

A.Y.P. Sébastien et al., Microstructure-Based Behavior Law for Globular Pearlitic Steels, J. Market. Res., 2019, 8(3), p 3373–3376.

J.M. O’Brien and W.F. Hosford, Spheroidization of Medium-Carbon Steels, J. Mater. Eng. Perform., 1997, 6(1), p 69–72.

ASTM E112. Standard Test Methods for Determining Average Grain Size. ASTM, 2021.

J. Arruabarrena and J.M.R. Ibabe, Enhancement of the AISI 5140 Cold Heading Wire Steel Spheroidization by Adequate Control of the Initial As-Rolled Microstructure, Metals, 2021, 11, p 1–14.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nora, J.V.P.D., Medeiros, J.L.B., Biehl, L.V. et al. The Influence of Thermal Cycles on the Performance and Spheroidization Process of SAE 8640 Steels. J. of Materi Eng and Perform 32, 4932–4940 (2023). https://doi.org/10.1007/s11665-022-07466-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07466-0