Abstract

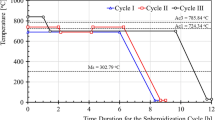

Spheroidization is a common technique to improve the formability and machinability of material. Multiple combinations of deformation level and annealing time were employed to optimize the microstructure in 22MnB5 steel, aiming to achieve maximum spheroidization and keeping the process most economical. The critical annealing temperature for spheroidization was decided through differential scanning calorimetry measurement. Spheroidization was achieved by annealing of as-received and three different amounts of cold-rolled material, namely 10, 20, and 30% reduction in thickness. Annealing was done at 720 °C for four different times, 10, 20, 40, and 60 h, at all deformation levels. Convoluted multiple whole profile fitting technique of x-ray diffraction pattern was used to estimate the stored dislocation density in the material after different deformation levels. The microstructural investigation was performed using optical microscopy, scanning electron microscopy and EBSD techniques. The extent of spheroidization was measured through the average aspect ratio of cementite precipitate. Mechanical properties were measured through surface and core micro-hardness of initial and spheroidized samples. Microstructural characterization showed that deformation produced sub-grains and low angle grain boundaries, facilitating an easy path for diffusion of carbon. However, it was also found that a very high amount of pre-strain is also detrimental to the spheroidization process because it results in the formation of very long and sharp cementite lamella, which required more annealing time for spheroidization. The best processing parameter for spheroidization of 22MnB5 steel, considering the optimum spheroidization and minimum cost of the process, was found as 20% cold rolling reduction followed by 20 h annealing.

Similar content being viewed by others

References

Y. Funakawa and Y. Nagataki, High Strength Steel Sheets for Weight Reduction of Automobiles, JFE Tech. Rep., 2019, 24, p 1–5.

J.H. Schmitt and T. Iung, New Developments of Advanced High-Strength Steels for Automotive Applications, C R Acad. Sci. II, 2018, 19, p 641–656.

H. Safari, H. Nahvi and M. Esfahanian, Improving Automotive Crash Worthiness Using Advanced High Strength Steels, Int. J. Crashworthiness, 2018, 23, p 645–659.

G. Venturato, S. Bruschi, A. Ghiotti and X. Chen, Numerical Modeling of the 22MnB5 Formability at High Temperature, Proced. Manuf., 2019, 29, p 428–434.

K. Ahn, Y. Jeong and J. Yoon, Thermo-Mechanical Constitutive Equation of 22MnB5 Steel Sheet for Hot Press Forming Process, Int. J. Precis. Eng. Manuf. Technol., 2019, 20, p 663–672.

P. Zhang, L. Zhu, C. Xi and J. Luo, Study on Phase Transformation in hot Stamping Process of USIBOR®1500 High-Strength Steel, Metals (Basel), 2019, 9, p 1–10.

E. Gracia-Escosa, I. García, J.J.D. Damborenea and A. Conde, Friction and Wear Behaviour of Tool Steels Sliding Against 22MnB5steel, J. Mater. Res. Technol., 2017, 6, p 241–50.

R. Song, D. Ponge, D. Raabe and R. Kaspar, Microstructure and Crystallographic Texture of an Ultrafine Grained C–Mn Steel and Their Evolution During Warm Deformation and Annealing, Acta Mater., 2005, 53, p 845–858.

R. Song, D. Ponge and D. Raabe, Mechanical Properties of an Ultrafine Grained C-Mn Steel Processed by Warm Deformation and Annealing, Acta Mater., 2005, 53, p 4881–4892.

R. Song, D. Ponge and D. Raabe, Improvement of the Work Hardening Rate Of Ultrafine Grained Steels Through Second Phase Particles, Scr. Mater., 2005, 52, p 1075–1080.

L. Storojeva, D. Ponge, R. Kaspar and D. Raabe, Development of Microstructure and Texture of Medium Carbon Steel During Heavy Warm Deformation, Acta Mater., 2004, 52, p 2209–2220.

N. Jia, Y.F. Shen, J.W. Liang, X.W. Feng, H.B. Wang and R.D.K. Misra, Nanoscale Spheroidized Cementite Induced Ultrahigh Strength-Ductility Combination in Innovatively Processed Ultrafine-Grained Low Alloy Medium-Carbon Steel, Sci. Rep., 2017, 7, p 2679.

G.E. Totten, Steel Heat Treatment Metallurgy and Technologies, CRC Press, Boca Raton, 2007.

D.X. Han, L.X. Du, B. Zhang et al., Effect of Deformation on Deformation-Induced Carbides and Spheroidization in Bearing Steel, J. Mater. Sci., 2019, 54(3), p 2612–2627.

H.L. Yi, Z.Y. Hou and Y.B. Xu, Acceleration of spheroidization in eutectoid steels by the addition of aluminium, Scr. Mater., 2012, 7–8(67), p 645–648.

H. Li, B. Wang, X. Song et al., New Spheroidizing Technique of Ultra-High Carbon Steel with Aluminium Addition, J. Iron. Steel Res. Int., 2006, 13(3), p 9–13.

B. Wang, X. Song and H. Peng, Design of a Spheroidization Processing for Ultrahigh Carbon Steels Containing Al, Mater. Des., 2007, 28(2), p 562–568.

Z.Q. Lv, B. Wang, Z.H. Wang et al., Effect of Cyclic Heat Treatments on Spheroidizing Behaviour of Cementite in High Carbon Steel, Mater. Sci. Eng. A, 2013, 574, p 143–148.

D. Hernandez-Silva, The Spheroidization of Cementite in a Medium Carbon Steel by Means of Subcritical and Inter Critical Annealing, ISIJ Int., 1992, 32(12), p 1297–1305.

A. Saha, D.K. Mondal and J. Maity, Effect of Cyclic Heat Treatment on Microstructure and Mechanical Properties of 0.6 wt.% Carbon Steel, Mater. Sci. Eng. A, 2010, 527(16), p 4001–4007.

A. Saha, D.K. Mondal, K. Biswas et al., Development of High Strength Ductile Hypereutectoid Steel by Cyclic Heat Treatment Process, Mater. Sci. Eng. A, 2012, 541, p 204–215.

R. Sabban, S. Bahl, K. Chatterjee et al., Globularization Using Heat Treatment in Additively Manufactured Ti-6Al-4V for High Strength and Toughness, Acta Mater., 2019, 162, p 239–254.

W.T. Yu, J. Li, C.B. Shi et al., Effect of Spheroidizing Annealing on Microstructure and Mechanical Properties of high-Carbon Martensitic Stainless Steel 8Cr13MoV, J. Mater. Eng. Perform., 2017, 26(2), p 478–487.

W. Hui, H. Dong, Y. Weng et al., Effect of Heat Treatment Parameters on Mechanical Properties Of High Strength Cr-Mo-V Steel, Acta Metall. Sin.-Chin. Ed., 2002, 38(10), p 1009–1014.

J.D. Verhoeven and E.D. Gibson, The Divorced Eutectoid Transformation in Steel, Metall. Mater. Trans. A, 1998, 29(4), p 1181–1189.

J.D. Verhoeven, The Role of the Divorced Eutectoid Transformation in the Spheroidization of 52100 Steel, Metall. Mater. Trans. A, 2000, 31(10), p 2431–2438.

G. Ribárik, T. Ungár and J. Gubicza, MWP-fit: A Program for Multiple Whole-Profile Fitting of Diffraction Peak Profiles by ab Initio Theoretical Functions, J. Appl. Crystallogr., 2001, 34, p 669.

M. Wilkens, The Determination of Density and Distribution of Dislocations in Deformed Single Crystals from Broadened x-ray Diffraction Profiles, Phys. Status Solidi A, 1970, 2, p 359.

G. Ribárik, J. Gubicza and T. Ungár, Correlation Between Strength and Microstructure of Ball-Milled Al-Mg Alloys Determined by x-ray Diffraction, Mater. Sci. Eng. A, 2004, 387, p 343.

C. Prasad, P. Bhuyan, C. Kaithwas, R. Saha and S. Mandal, Microstructure Engineering by Dispersing Nano-Spheroid Cementite in Ultrafine-Grained Ferrite and Its Implications on Strength-Ductility Relationship in High Carbon Steel, Mater. Des., 2018, 139, p 324–335.

W.W. Mullins, Flattening of a Nearly Plane Solid Surface due to Capillarity, J. Appl. Phys., 1959, 30, p 77–83.

Y.L. Tian and R.W. Kraft, Kinetics of Pearlite Spheroidization, Metall. Trans. A., 1987, 18, p 1359–1369.

J. Moon, H. Jeong, J. Lee and C. Lee, Particle Coarsening Kinetics Considering Critical Particle Size in the Presence of Multiple Particles in the Heat-Affected Zone of a Weld, Mater. Sci. Eng. A, 2008, 483–484, p 633–636.

A.M. Cree, R.G. Faulkner and A.T. Lyne, Cementite Particle Coarsening During Spheroidization of Bearing Steel SAE 52100, Mater. Sci. Technol., 1995, 11, p 566–571.

R. Xie, S. Lu, W. Li, Y. Tian and L. Vitos, Dissociated Dislocation-Mediated Carbon Transport and Diffusion in Austenitic Iron, Acta Mater., 2020, 191, p 3–50.

Acknowledgments

The authors acknowledge the Department of materials engineering, IISc Bangalore, for providing all the necessary facilities to do this work. The authors also acknowledge the extensive use of microscopy facilities at the Advanced Facility for Microscopy and Microanalysis (AFMM) at Indian Institute of Science, Bangalore. The author acknowledges Aisin Automotive Haryana Pvt. Ltd., for providing funds to support the work.

Funding

This work was supported by Aisin Automotive Haryana Pvt. Ltd., Bangalore—563133, India.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shankar, G., Singh, V.K., Chepuri, A. et al. Influence of Pre-strain on the Cementite Spheroidization of 22MnB5 Steel and Its Effect on Mechanical Properties. J. of Materi Eng and Perform 31, 7484–7500 (2022). https://doi.org/10.1007/s11665-022-06785-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06785-6