Abstract

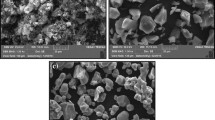

Automotive monocoque is in need of AA7075 with enhanced strength and hardness properties. Fabrication of Surface Hybrid Composites (SHCs) by Friction Stir Processing is a prominent technique to satisfactorily enhance the aforementioned characteristics. SHCs are formed through different volume proportions of Al2O3/SiC reinforcements. Heat generation during the processing stage shows a linear trend along the longitudinal axis due to the thermal conductivity of AA7075. Microstructure of composites is observed with fine grain formation and homogeneous distribution of reinforcements. X-ray Diffraction pattern confirms the existence of both reinforcements in matrix alloy. Specimens with identical volume ratio of Al2O3 and SiC particles depict the superior micro-hardness of 265 VHN which is 8.5 and 19.08% higher than the individual contribution of reinforcements. This is attributed to the homogeneous settlement of reinforcements and particle pinning with parent matrix. Addition of Al2O3 improves the impact toughness due to its wettability with base AA7075 as a result of Al-Al bond. Incorporation of SiC particles enhances the Ultimate Tensile Strength of the composites by virtue of its high load-bearing capacity. Fracto-graphic analysis of the specimens with different Al2O3/SiC weight ratios indicated the fractures along the breakdown of reinforcement particles.

Similar content being viewed by others

References

R.S. Mishra and Z. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R. Rep., 2005, 50(1-2), p 1-78.

H. Li, Y. Qiao, S. Lu, C. Li, F. Wang, C. Sun, and L. Jiao, Study on Microstructure Evolution and Strengthening and Toughening of Friction Stir Processed AA6082-4% Al3Zr In-Situ Composites, J. Mater. Eng. Perform., 2022, 31, p 5221–5230.

D.K. Sharma, V. Badheka, V. Patel and G. Upadhyay, Recent Developments in Hybrid Surface Metal Matrix Composites Produced by Friction Stir Processing: A Review, Journal of Tribology, 2021, 143(5), p 050801.

V. Patel, V. Badheka, W. Li and S. Akkireddy, Hybrid Friction Stir Processing with Active Cooling Approach to Enhance Superplastic Behavior of AA7075 Aluminum Alloy, Arch. Civil Mech. Eng., 2019, 19(4), p 1368-1380.

D. Yadav and R. Bauri, Effect of Friction Stir Processing on Microstructure and Mechanical Properties of Aluminium, Mater. Sci. Eng. A, 2012, 539, p 85-92.

S.R. Nathan, V. Balasubramanian, S. Malarvizhi and A. Rao, Effect of Tool Shoulder Diameter on Stir Zone Characteristics of Friction Stir Welded HSLA Steel Joints, Trans. Indian Inst. Met., 2016, 69(10), p 1861-1869.

S. Kandasamy, P. Rathinasamy, N. Nagarajan, K. Arumugam, R. Rathanasamy and G.V. Kaliyannan, Corrosion Behavioral Studies on AA7075 Surface Hybrid Composites Tailored Through Friction Stir Processing, Anti-Corrosion Methods Mater., 2020, 67(4), p 345-355.

A. Dolatkhah, P. Golbabaei, M.B. Givi and F. Molaiekiya, Investigating Effects of Process Parameters on Microstructural and Mechanical Properties of Al5052/SiC Metal Matrix Composite Fabricated via Friction Stir Processing, Mater. Des., 2012, 37, p 458-464.

H. Uzun, Friction Stir Welding of SiC Particulate Reinforced AA2124 Aluminium Alloy Matrix Composite, Mater. Des., 2007, 28(5), p 1440-1446.

S. Senthil, R. Parameshwaran, S.R. Nathan and S. Karthi, Non-Destructive Testing and Evaluation of Friction Stir Welded AA6063 Circularly Butted Pipes, Russ. J. Nondestr. Test., 2019, 55(12), p 957-966.

S. Senthil, S.R. Nathan and R. Parameshwaran, Experimental Investigation on Joining Process of Aluminium Alloy 6063-T6 Pipes Using Hybrid Friction Stir Welding, J. Braz. Soc. Mech. Sci. Eng., 2021, 43(7), p 1-9.

S. Senthil, S. Ragu Nathan, R. Parameshwaran, and M. Bhuvanesh Kumar, Comparative Study on Mechanical Performances of Circular and Flat Geometry Welds in Friction Stir Welding of Aluminium Alloy, Arch. Metall. Mater., 2021, 66, p 881–886.

S. Arulvel, Development of Multi-pass Processed AA6082/SiCp Surface Composite Using Friction Stir Processing and its Mechanical and Tribology Characterization, Surf. Coat. Technol., 2020, 394, p 125900.

V. Patel, W. Li, X. Liu, Q. Wen, Y. Su, J. Shen and B. Fu, Tailoring Grain Refinement Through Thickness in Magnesium Alloy via Stationary Shoulder Friction Stir Processing and Copper Backing Plate, Mater. Sci. Eng., A, 2020, 784, p 139322.

M. Salehi, H. Farnoush and J.A. Mohandesi, Fabrication and Characterization of Functionally Graded Al-SiC Nanocomposite by Using a Novel Multistep Friction Stir Processing, Mater. Des., 2014, 63, p 419-426.

Y. Mazaheri, F. Karimzadeh and M. Enayati, A Novel Technique for Development of A356/Al2O3 Surface Nanocomposite by Friction Stir Processing, J. Mater. Process. Technol., 2011, 211(10), p 1614-1619.

H. Rana, V. Badheka and A. Kumar, Fabrication of Al7075/B4C Surface Composite by Novel Friction Stir Processing (FSP) and Investigation on Wear Properties, Procedia Technol., 2016, 23, p 519-528.

D.K. Sharma, V. Patel, V. Badheka, K. Mehta and G. Upadhyay, Fabrication of Hybrid Surface Composites AA6061/(B4C+ MoS2) via Friction Stir Processing, J. Tribol., 2019, 141(5), p 052201.

D. Sharma, V. Patel, V. Badheka, K. Mehta and G. Upadhyay, Different Reinforcement Strategies of Hybrid Surface Composite AA6061/(B4C+ MoS2) Produced by Friction Stir Processing, Materialwiss. Werkstofftech., 2020, 51(11), p 1493-1506.

K. Periasamy, M. Jayaraman and S. Rajkumar, Mechanical Properties of 7075-T6 Aluminium Alloy Surface Hybrid Composites Synthesised by Friction Stir Processing, Int. J. Rapid Manuf., 2019, 8(1-2), p 52-64.

D. Aruri, K. Adepu, K. Adepu and K. Bazavada, Wear and Mechanical Properties of 6061-T6 Aluminum Alloy Surface Hybrid Composites [(SiC+ Gr) and (SiC+ Al2O3)] Fabricated by Friction Stir Processing, J. Mater. Res. Technol., 2013, 2(4), p 362-369.

M. Azadi, M. Shamanian, and M.A. Golozar, Hardness and Wear Behavior of Al7075/TiC/MoS2 Surface Hybrid Composite Produced by Friction Stir Processing, Iran. J. Surf. Sci. Eng., 2017, 12(31), p 41–51.

N. Pol, G. Verma, R. Pandey and T. Shanmugasundaram, Fabrication of AA7005/TiB2-B4C Surface Composite by Friction Stir Processing: Evaluation of Ballistic Behaviour, Def. Technol., 2019, 15(3), p 363-368.

M. Bahrami, N. Helmi, K. Dehghani and M.K.B. Givi, Exploring the Effects of SiC Reinforcement Incorporation on Mechanical Properties of Friction Stir Welded 7075 Aluminum Alloy: Fatigue Life, Impact Energy, Tensile Strength, Mater. Sci. Eng. A, 2014, 595, p 173-178.

J. Han, H. Li, Z. Zhu, F. Barbaro, L. Jiang, H. Xu and L. Ma, Microstructure and Mechanical Properties of Friction Stir Welded 18Cr-2Mo Ferritic Stainless Steel Thick Plate, Mater. Des., 2014, 63, p 238-246.

H. Deore, J. Mishra, A. Rao, H. Mehtani and V. Hiwarkar, Effect of Filler Material and Post Process Ageing Treatment on Microstructure, Mechanical Properties and Wear Behaviour of Friction Stir Processed AA 7075 Surface Composites, Surf. Coat. Technol., 2019, 374, p 52-64.

L.S. Raju and A. Kumar, Influence of Al2O3 Particles on the Microstructure and Mechanical Properties of Copper Surface Composites Fabricated by Friction Stir Processing, Defence Technology, 2014, 10(4), p 375-383.

M. Santella, T. Engstrom, D. Storjohann and T.-Y. Pan, Effects of Friction Stir Processing on Mechanical Properties of the Cast Aluminum Alloys A319 and A356, Scripta Mater., 2005, 53(2), p 201-206.

Z. Ma, A. Pilchak, M. Juhas and J. Williams, Microstructural Refinement and Property Enhancement of Cast Light Alloys via Friction Stir Processing, Scripta Mater., 2008, 58(5), p 361-366.

R. Butola, L. Tyagi, R.M. Singari, Q. Murtaza, H. Kumar and D. Nayak, Mechanical and Wear Performance of Al/SiC Surface Composite Prepared Through Friction Stir Processing, Mater. Res. Express, 2021, 8(1), p 016520.

G.M. Kumar and R.P. Kumar, Characterization of Pine Needle Ash Particulates Reinforced Surface Composite Fabricated by Friction Stir Process, Mater. Res. Express, 2019, 6(4), p 046539.

A.K. Srivastava, N.K. Maurya, A.R. Dixit, S.P. Dwivedi, A. Saxena and M. Maurya, Experimental Investigations of A359/Si3N4 Surface Composite Produced by Multi-pass Friction Stir Processing, Mater. Chem. Phys., 2021, 257, p 123717.

I. Lee, C. Hsu, C. Chen, N. Ho and P. Kao, Particle-Reinforced Aluminum Matrix Composites Produced from powder Mixtures via Friction Stir Processing, Compos. Sci. Technol., 2011, 71(5), p 693-698.

K.A. Kumar, S. Natarajan, M. Duraiselvam and S. Ramachandra, Synthesis, Characterization and Mechanical Behavior of Al 3003-TiO2 Surface Composites Through Friction Stir Processing, Mater. Manuf. Processes, 2019, 34(2), p 183-191.

D.M. Neto and P. Neto, Numerical Modeling of Friction Stir Welding Process: A Literature Review, Int. J. Adv. Manuf. Technol., 2013, 65(1-4), p 115-126.

E.R. Mahmoud, M. Takahashi, T. Shibayanagi and K. Ikeuchi, Wear Characteristics of Surface-Hybrid-MMCs Layer Fabricated on Aluminum Plate by Friction Stir Processing, Wear, 2010, 268(9-10), p 1111-1121.

K. Suganeswaran, R. Parameshwaran, P. Thangavel, N. Nithyavathy and T. Sivasakthivel, Investigations on Micro Hardness, Electrical and Thermal Conductivity of AA7075 Surface Hybrid Composites Produced Through Friction Stir Processing, Mater. Res. Express, 2019, 6(11), p 116548.

T. Prater, Solid-State Joining of Metal Matrix Composites: A Survey of Challenges and Potential Solutions, Mater. Manuf. Processes, 2011, 26(4), p 636-648.

K. Jata and S. Semiatin, Continuous Dynamic Recrystallization During Friction Stir Welding of High Strength Aluminum Alloys, Scr. Mater., 2000, 43(8), p 743–749.

G. Bussu and P. Irving, The Role of Residual Stress and Heat Affected Zone Properties on Fatigue Crack Propagation in Friction Stir Welded 2024-T351 Aluminium Joints, Int. J. Fatigue, 2003, 25(1), p 77-88.

A. Shafiei-Zarghani, S. Kashani-Bozorg and A. Zarei-Hanzaki, Microstructures and Mechanical Properties of Al/Al2O3 Surface Nano-composite Layer Produced by Friction Stir Processing, Mater. Sci. Eng., A, 2009, 500(1-2), p 84-91.

H.-K. Kang, Microstructure and Electrical Conductivity of High Volume Al2O3-Reinforced Copper Matrix Composites Produced by Plasma Spray, Surf. Coat. Technol., 2005, 190(2-3), p 448-452.

Q. Zeng, J. Guo, X. Gu, X. Zhao and X. Liu, Wetting Behaviors and Interfacial Reaction Between Sn-10Sb-5Cu High Temperature Lead-Free Solder and Cu Substrate, J. Mater. Sci. Technol., 2010, 26(2), p 156-162.

H.S. Grewal, H. Singh, A. Agrawal, H.S. Arora, Friction stir processing of mild steel to enhance its surface hardness, In: Advanced Materials Research, 2013, Trans Tech Publ, pp 117-121.

K. Suganeswaran, R. Parameshwaran, R. Sathiskumar, T. Ram Prabhu, N. Nithyavathy, Influence of Fly Ash and Emery based particulate reinforced AA7075 surface composite processed through friction stir processing, In: Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 09544089211072719 (2022)

A. Kurt, I. Uygur and E. Cete, Surface Modification of Aluminium by Friction Stir Processing, J. Mater. Process. Technol., 2011, 211(3), p 313-317.

K. Fuse, V. Badheka, V. Patel and J. Andersson, Dual Sided Composite Formation in Al 6061/B4C Using Novel Bobbin Tool Friction Stir Processing, J. Market. Res., 2021, 13, p 1709-1721.

S. Kumar, R.S. Panwar and O. Pandey, Effect of Dual Reinforced Ceramic Particles on High Temperature Tribological Properties of Aluminum Composites, Ceram. Int., 2013, 39(6), p 6333-6342.

K. Suganeswaran, R. Parameshwaran, T. Mohanraj and N. Radhika, Influence of Secondary Phase Particles Al2O3/SiC on the Microstructure and Tribological Characteristics of AA7075-Based Surface Hybrid Composites Tailored Using Friction Stir Processing, Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci., 2021, 235(1), p 161-178.

K. Suganeswaran, P. Muthukumar, R. Parameshwaran, N. Nithyavathy, T. Mohanraj, and K. Deepandurai, Optimization of FSP Parameters to Fabricate AA7075-Based Surface Composites Using Taguchi Technique and TOPSIS Approach, J. Adhes. Sci. Technol., 2022. https://doi.org/10.1080/01694243.2022.2046247.

B. Vijaya Ramnath, C. Elanchezhian, R. Annamalai, S. Aravind, T. Sri Ananda Atreya, V. Vignesh and C. Subramanian, Aluminium Metal Matrix Composites-A Review, Rev. Adv. Mater. Sci., 2014, 38(5), p 55-60.

P. Poddar, V. Srivastava, P. De and K. Sahoo, Processing and Mechanical Properties of SiC Reinforced Cast Magnesium Matrix Composites by Stir Casting Process, Mater. Sci. Eng. A, 2007, 460, p 357-364.

A. Kumar, K. Pal and S. Mula, Simultaneous Improvement Of Mechanical Strength, Ductility and Corrosion Resistance of Stir Cast Al7075-2% SiC Micro-and Nanocomposites by Friction Stir Processing, J. Manuf. Process., 2017, 30, p 1-13.

V. Patel, W. Li, A. Vairis and V. Badheka, Recent Development in Friction Stir Processing as a Solid-State Grain Refinement Technique: Microstructural Evolution and Property Enhancement, Crit. Rev. Solid State Mater. Sci., 2019, 44(5), p 378-426.

V. Patel, W. Li, X. Liu, Q. Wen and Y. Su, Through-Thickness Microstructure and Mechanical Properties in Stationary Shoulder Friction Stir Processed AA7075, Mater. Sci. Technol., 2019, 35(14), p 1762-1769.

R. Kapoor, K. Kandasamy, R. Mishra, J. Baumann and G. Grant, Effect of Friction Stir Processing on the Tensile and Fatigue Behavior of a Cast A206 Alloy, Mater. Sci. Eng., A, 2013, 561, p 159-166.

A. Mazahery, H. Abdizadeh and H. Baharvandi, Development of High-Performance A356/nano-Al2O3 Composites, Mater. Sci. Eng., A, 2009, 518(1-2), p 61-64.

P. Muthukumar and S. Jerome, Surface Coating (Al/Cu & Al/SiC) Fabricated by Direct Particle Injection Tool for Friction Stir Processing: Evolution of Phases, Microstructure and Mechanical Properties, Surf. Coat. Technol., 2019, 366, p 190-198.

S. Mishra and A. Satapathy, Ceramic Particulate Filled ZA-27 Metal Matrix Composites: Comparative Analysis, Mater. Sci. Technol., 2014, 30(12), p 1495-1499.

D. Zhang, S. Wang, C. Qiu and W. Zhang, Superplastic Tensile Behavior of a Fine-Grained AZ91 Magnesium Alloy Prepared by Friction Stir Processing, Mater. Sci. Eng., A, 2012, 556, p 100-106.

Acknowledgments

The authors are sincerely thankful to NIT-Trichy and Karunya University to complete the morphological analysis of fabricated specimens. The authors are thankful to Dr. V. Ganeshan, Emeritus Professor, Indian Institute of Technology (MADRAS), Chennai, for his valuable suggestions and support throughout this investigation.

Funding

There is no funding for this investigation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Research Involving Human Participants and/or Animals

The Author(s) are stating that no human participants or animals were involved to carry out this investigation.

Informed Consent

This manuscript has not been published or presented elsewhere in part or in entirety and is not under consideration by another journal. We have read and understood your journal’s policies, and we believe that neither the manuscript nor the study violates any of these. There are no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Suganeswaran, K., Ragu Nathan, S., Parameshwaran, R. et al. Characterization of AA7075 Surface Composites with Ex Situ Al2O3/SiC Reinforcements Tailored Using Friction Stir Processing. J. of Materi Eng and Perform 32, 3617–3632 (2023). https://doi.org/10.1007/s11665-022-07354-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07354-7