Abstract

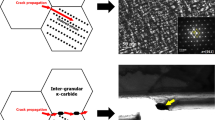

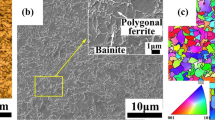

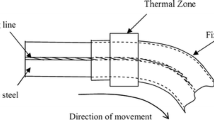

The effects of welding heat inputs and reheating processes with various cooling rates were investigated by thermally simulated experiments on the microstructure, tensile strength and impact toughness of high-strength weld metals containing 4% Ni. The microstructure was characterized by scanning electron microscopy (SEM) and electron backscatter diffraction (EBSD). As a result, an extended continuous cooling transformation (e-CCT) diagram was established. The change in the microstructures is affected from three perspectives. The coarser grains and the generated martensite-austenite (M-A) constituents lead to the deterioration of impact toughness and ultimate tensile strength with the increase in heat inputs. The reheating processes with various cooling rates can change the microstructure, hardness, impact toughness and large angle boundaries. When the heat input increases from 15.8 to 17.9 kJ/cm, the content of block ferrite decreases from the initial 18.9 to 8.5%, and the content of lath bainite increases accordingly. When the heat input is 20.6 kJ/cm, the content of block ferrite increases is 17.3% and the rest is lath bainite. The hardness first decreases in the lower cooling rate range (0.05~1 °C/s) and then increases at higher cooling rates. The minimum hardness at a cooling rate of 1 °C/s may be related to the decrease in the coarse block M-A constituents. The reheating process decreases the impact toughness at room temperature from 83 to 37.45 J for the specimen with a cooling rate of 30 °C/s and increases the impact toughness from 83 to 99.71 J for the specimen with a cooling rate of 0.5 °C/s. The impact toughness at −50 °C after the reheating processes decreases from 74 to 32 J, and the lowest impact toughness after the reheating processes reaches only 32 J. The proportion of high-angle grain boundaries (HAGBs) first increases from 12.13 to 26. 44% and then decreases to 16.34% with increasing cooling rate.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

References

R.O. Ritchie, The Conflicts Between Strength and Toughness, Nat. Mater., 2011, 10(11), p 817–822.

E. Surian, J. Trotti, A. Cassanelli and L. De Vedia, Influence of chromium on the mechanical properties and microstructure of weld metal from a high-strength SMA electrode, Weld. J., 1994, 73, p 45-s.

R. Pouriamanesh, K. Dehghani, R. Vallant and N. Enzinger, Effect of Ti Addition on the Microstructure and Mechanical Properties of Weld Metals in HSLA Steels, J. Mater. Eng. Perform., 2018, 27(11), p 6058–6068.

K. Xu, T. Fang, L. Zhao, H. Cui and F. Lu, Effect of trace element on microstructure and fracture toughness of weld metal, Acta Metall. Sin. (Engl. Lett.), 2020, 33(3), p 425–436.

Y. Kang, S. Jeong, J.-H. Kang and C. Lee, Factors affecting the inclusion potency for acicular ferrite nucleation in high-strength steel welds, Metall. Mater. Trans. A, 2016, 47(6), p 2842–2854.

J. Yang, C. Huang, C. Huang and J. Aoh, Influence of acicular ferrite and bainite microstructures on toughness for an ultra-low-carbon alloy steel weld metal, J. Mater. Sci. Lett., 1993, 12(16), p 1290–1293.

T. Zhang, Z. Li, S. Ma, S. Kou and H. Jing, High strength steel (600–900 MPa) deposited metals: microstructure and mechanical properties, Sci. Technol. Weld. Join., 2016, 21(3), p 186–193.

F. Liu, C. Tan, X. Gong, L. Wu, B. Chen, X. Song and J. Feng, A comparative study on microstructure and mechanical properties of HG785D steel joint produced by hybrid laser-MAG welding and laser welding, Opt. Laser Technol., 2020, 128, p 106247.

E. Keehan, L. Karlsson, H.-O. Andrén and H. Bhadeshia, Influence of carbon, manganese and nickel on microstructure and properties of strong steel weld metals: part 3–increased strength resulting from carbon additions, Sci. Technol. Weld. Join., 2006, 11(1), p 19–24.

E.J. Barrick and J.N. DuPont, Microstructural characterization and toughness evaluation of 10 wt% Ni steel weld metal gas tungsten arc and gas metal arc weld fusion zones, Mater. Sci. Eng. A., 2020, 796, p 140043.

S. Khodir, T. Shibayanagi, M. Takahashi, H. Abdel-Aleem and K. Ikeuchi, Microstructural evolution and mechanical properties of high strength 3–9% Ni-steel alloys weld metals produced by electron beam welding, Mater. Des., 2014, 60, p 391–400.

J. Hu, L.X. Du and J.J. Wang, Effect of cooling procedure on microstructures and mechanical properties of hot rolled Nb–Ti bainitic high strength steel, Mater. Sci. Eng. A., 2012, 554, p 79–85.

J. Zhang, K. Cui, B. Huang, X. Mao and M. Zheng, Influence of heat input on the microstructure and mechanical properties of CLAM steel multilayer butt-welded joints, Fusion Eng. Des., 2020, 152, p 111413.

D.C. Ramachandran, J. Moon, C.H. Lee, S.D. Kim, J.H. Chung, E. Biro and Y.D. Park, Role of bainitic microstructures with MA constituent on the toughness of an HSLA steel for seismic resistant structural applications, Mater. Sci. Eng. A., 2021, 801, p 140390.

Ö. Üstündağ, S. Gook, A. Gumenyuk and M. Rethmeier, Hybrid laser arc welding of thick high-strength pipeline steels of grade X120 with adapted heat input, J. Mater. Process. Technol., 2020, 275, p 116358.

X. Yang, X. Di, X. Liu, D. Wang and C. Li, Effects of heat input on microstructure and fracture toughness of simulated coarse-grained heat affected zone for HSLA steels, Mater. Charact., 2019, 155, p 109818.

Q. Chu, S. Xu, X. Tong, J. Li, M. Zhang, F. Yan, W. Zhang, Z. Bi and C. Yan, Comparative study of microstructure and mechanical properties of X80 SAW welds prepared using different wires and heat inputs, J. Mater. Eng. Perform., 2020, 29(7), p 4322–4338.

R. Cao, J.J. Yuan, Z.K. Xiao, J.Y. Ma, G.J. Mao, X.K. Zhang and J.H. Chen, Sources of variability and lower values in toughness measurements of weld metals, J. Mater. Eng. Perform., 2017, 26, p 2472–2483.

Y. Kang, G. Park, S. Jeong and C. Lee, Correlation between microstructure and low-temperature impact toughness of simulated reheated zones in the multi-pass weld metal of high-strength steel, Metall. Mater. Trans. A, 2018, 49(1), p 177–186.

X. Wang, Y. Nan, Z. Xie, Y. Tsai, J. Yang and C. Shang, Influence of welding pass on microstructure and toughness in the reheated zone of multi-pass weld metal of 550 MPa offshore engineering steel, Mater. Sci. Eng. A., 2017, 702, p 196–205.

X. Wang, Y. Tsai, J. Yang, Z. Wang, X. Li, C. Shang and R. Misra, Effect of interpass temperature on the microstructure and mechanical properties of multi-pass weld metal in a 550-MPa-grade offshore engineering steel, Weld. World., 2017, 61(6), p 1155–1168.

P. Haslberger, S. Holly, W. Ernst and R. Schnitzer, Microstructure and mechanical properties of high-strength steel welding consumables with a minimum yield strength of 1100 MPa, J. Mater. Sci., 2018, 53(9), p 6968–6979.

E. Keehan, L. Karlsson, H.-O. Andrén and H. Bhadeshia, Influence of carbon, manganese and nickel on microstructure and properties of strong steel weld metals: part 2–impact toughness gain resulting from manganese reductions, Sci. Technol. Weld. Joining, 2006, 11(1), p 9–18.

E. Keehan, L. Karlsson and H.-O. Andrén, Influence of carbon, manganese and nickel on microstructure and properties of strong steel weld metals: part 1–effect of nickel content, Sci. Technol. Weld. Joining, 2006, 11(1), p 1–8.

X. Di, M. Tong, C. Li, C. Zhao and D. Wang, Microstructural evolution and its influence on toughness in simulated inter-critical heat affected zone of large thickness bainitic steel, Mater. Sci. Eng. A., 2019, 743, p 67–76.

S. Kou, Welding Metallurgy, Wiley, New Jersey, 2003.

G.J. Mao, R. Cao, X.L. Guo, Y. Jiang and J.H. Chen, In-situ observation of kinetic processes of lath bainite nucleation and growth by laser scanning confocal microscope in reheated weld metals, Metall. Mater. Trans. A, 2017, 48(12), p 5783–5799.

S. Zajac, V. Schwinn and K.H. Tacke, Characterization and quantication of complex bainitic microstructures in high and ultra-high strength linepipe steels, Mater. Sci., 2005, 500–501, p 387–394.

L. Morsdorf, C.C. Tasan, D. Ponge et al., 3D structural and atomic-scale analysis of lath martensite: Effect of the transformation sequence, Acta Mater., 2015, 95, p 366–377.

G.J. Mao, R. Cao, J. Yang, Y. Jiang, S. Wang, X.L. Guo and J.H. Chen, Effect of nickel contents on the microstructure and mechanical properties for low-carbon bainitic weld metals, J. Mater. Eng. Perform., 2017, 26(5), p 2057–2071.

J.H. Chen and R. Cao, Micromechanism of cleavage fracture of metals: a comprehensive microphysical model for cleavage cracking in metals, Butterworth-Heinemann, United Kingdom, 2014.

R. Cao, X.B. Zhang, Z. Wang, Y. Peng, W.S. Du, Z.L. Tian and J.H. Chen, Investigation of microstructural features determining the toughness of 980 MPa bainitic weld metal, Metall. Mater. Trans. A., 2014, 45(2), p 815–834.

K.F. Chung, H.C. Ho, Y.F. Hu, K. Wang and D.A. Nethercot, Experimental evidence on structural adequacy of high strength s690 steel welded joints with different heat input energy, Eng. Struct., 2020, 204, p 110151.

Q.W. Wang, C.S. Li, J. Chen and X.Y. Tu, Effects of heat input on microstructure and mechanical properties of Fe–2Cr–Mo–0.12C steel, Mater. Sci. Technol., 2017, 34, p 1–9.

N. Huda, A.R. Midawi, J. Gianetto, R. Lazor and A.P. Gerlich, Influence of martensite-austenite (MA) on impact toughness of X80 line pipe steels, Mater. Sci. Eng. A., 2016, 662, p 481–491.

L. Lan, C. Qiu, D. Zhao, X. Gao and L. Du, Analysis of microstructural variation and mechanical behaviors in submerged arc welded joint of high strength low carbon bainitic steel, Mater. Sci. Eng. A, 2012, 558, p 592–601.

A. Chabok, E. Van der Aa, J.T.M. De Hosson and Y. Pei, Mechanical behavior and failure mechanism of resistance spot welded DP1000 dual phase steel, Mater. Des., 2017, 124, p 171–182.

A. Lambert-Perlade, A.F. Gourgues and A. Pineau, Austenite to bainite phase transformation in the heat-affected zone of a high strength low alloy steel, Acta. Mater., 2004, 52, p 2337–2348.

Acknowledgments

This work was financially supported by National Nature Science Foundation of China (Nos. 51761027, 51675255, 51961024, 52071170). The Lanzhou Science and Technology Department Project (2019-1-49).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dong, W., Ma, C., Li, W. et al. Effects of Various Heat Inputs and Reheating Processes on the Microstructure and Properties of Low-Carbon Bainite Weld Metals Containing 4% Ni. J. of Materi Eng and Perform 31, 10187–10204 (2022). https://doi.org/10.1007/s11665-022-07061-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07061-3