Abstract

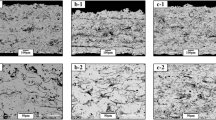

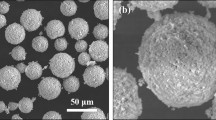

Calcium–magnesium–alumino-silicate (CMAS) corrosion is one of the important causes of failure in thermal barrier coatings (TBCs). Herein, 8YSZ (8%Y2O3-ZrO2) single and YAG (Y3Al5O12)/8YSZ double ceramic-layered (DCL) TBCs were deposited on the Al2O3 substrate by atmospheric plasma spraying, respectively. The CMAS corrosion tests were conducted at 1250 °C for 1, 4, and 12 h, as well as on YAG/CMAS mixed powder (mass ratio 1:1) for 12 h. The microstructure and the corrosion products were analyzed to reveal the CMAS corrosion processes and mechanisms of these two types of TBCs. Results showed that YAG particle surface layer is slightly corroded by molten CMAS after 12 h at 1250 °C, which proved the good CMAS corrosion resistance and high-temperature stability of YAG. For the pure 8YSZ TBCs, the coating phase started to transfer from the as-sprayed tetrahedral phase to a monoclinic phase after corrosion for 1 h, and CMAS infiltrated the 8YSZ ceramic layer completely after 12 h. However, for the YAG/8YSZ DCL TBCs, only the high-melting-point apatite phase formed on the surface of TBCs blocked the further infiltration of CMAS by slowing further corrosion of CMAS. The protective apatite phase isolated CMAS from the internal YAG, keeping the bottom 8YSZ ceramic layer intact and extensively reducing the further damage to these TBCs.

Similar content being viewed by others

References

Q. Chen, P. Hu, and J. Pu, Interfacial Interaction and Roughness Parameters Effects on the Residual Stresses in DCL-TBC System with Different Thickness Distributions, Ceram. Int., 2021, 47(2), p 2781–2792.

A.C. Karaoglanli, K.M. Doleker, B. Demirel, A. Turk, and R. Varol, Effect of shot Peening on the Oxidation Behavior of Thermal Barrier Coatings, Appl. Surf. Sci., 2015, 354, p 314–322.

R. Darolia, Thermal Barrier Coatings Technology: Critical Review, Progress Update, Remaining Challenges and Prospects, Int. Mater. Rev., 2013, 58(6), p 315–348.

T. Steinke, D. Sebold, and D.E. Mack, A novel Test Approach for plasma-Sprayed Coatings Tested Simultaneously under CMAS and Thermal Gradient Cycling Conditions, Surf. Coat. Tech., 2010, 205(7), p 2287–2295.

A. Sharma, G. Witz, P.C. Howell, and N. Hitchman, Interplay of the Phase and the Chemical Composition of the Powder Feedstock on the Properties of Porous 8YSZ Thermal Barrier Coatings, J. Eur. Ceram. Soc., 2020, 41, p 3706–3716.

L.Y. Chen, X.X. Tian, and H.Y. Wang, Phase Interaction Induced Texture in a Plasma Sprayed-Remelted NiCrBSi Coating during Solidification: An Electron Backscatter Diffraction Study, Surf. Coat. Tech., 2019, 358, p 467–480.

J.J. Gomezchavez, R. Naraparaju, and C. Mikulla, Comparative Study of EB-PVD Gadolinium-Zirconate and Yttria-Rich Zirconia Coatings Performance against Fe-Containing Calcium-Magnesium-Aluminosilicate (CMAS) Infiltration, Corros. Sci., 2021, 190, p 190660.

P. Sang, L.Y. Chen, and C. Zhao, Particle Size-Dependent Microstructure, Hardness and Electrochemical Corrosion Behavior of Atmospheric Plasma Sprayed NiCrBSi Coatings, Metals, 2019, 9(12), p 1342.

Y. Ozgurluk, A.C. Karaoglan, and H. Ahlatci, Comparison of Calcium-Magnesium-Alumina-Silicate (CMAS) Resistance Behavior of Produced with Electron Beam Physical Vapor Deposition (EB-PVD) Method YSZ and Gd2Zr2O7/YSZ Thermal Barrier Coatings Systems, Vacuum, 2021, 194, p 110576.

W. Fan, X. Song, and Y. Huang, Structure Change and Phase Transition Distribution Caused by CMAS Corrosion of YSZ Coating, J. Inorg. Mater., 2021, 36(10), p 1059.

A. Aygun, A.L. Vasiliev, N.P. Padture, and X. Ma, Novel Thermal Barrier Coatings that are Resistant to High-Temperature Attack by Glassy Deposits, Acta. Mater., 2007, 55(20), p 6734–6745.

H. Fang, W. Wang, J. Huang, and D. Ye, Investigation of CMAS Resistance of Sacrificial Plasma-Sprayed Mullite-YSZ Protective Layer on 8YSZ Thermal Barrier Coating, Corros. Sci., 2020, 173, p 108764.

S.H. Liu, C.X. Li, and H.Y. Zhang, A Novel Structure of YSZ Coatings by Atmospheric Laminar Plasma Spraying Technology, Scr. Mater., 2018, 153, p 73–76.

G. Mauer, M.O. Jarligo, D.E. Mack, and R. Vaßen, Plasma-Sprayed Thermal Barrier Coatings: New Materials, Processing Issues, and Solutions, J. Therm. Spray. Techn., 2013, 22(5), p 646–658.

S.H. Liu, J.P. Trelles, and A.B. Murphy, Low-Pressure Plasma-Induced Physical Vapor Deposition of Advanced Thermal Barrier Coatings: Microstructures, Modelling and Mechanisms, Mater. Today Phys., 2021, 21, p 100481.

S. Lakiza, O. Fabrichnay, C.H. Wang, M. Zinkevich, and Aldinger, Phase Diagram of the ZrO2-Gd2O3-Al2O3 System, J. Eur. Ceram. Soc., 2006, 26(3), p 233–246.

R. Vaßen, A. Stuke, and D. Stöver, Recent Developments in the field of Thermal Barrier Coatings, J. Therm. Spray. Techn., 2009, 18(2), p 181–186.

S. Kramer, J. Yang, and C.G. Levi, Infiltration-Inhibiting Reaction of Gadolinium Zirconate Thermal Barrier Coatings with CMAS Melts, J. Am. Ceram. Soc., 2008, 91(2), p 576–583.

G. Dwivedi, V. Viswanathan, S. Sampath, A. Shyam, E. Lara-Curzio, and K. Faber, Fracture Toughness of Plasma-Sprayed Thermal Barrier Ceramics: Influence of Processing, Microstructure, and Thermal Aging, J. Am. Ceram. Soc., 2014, 97(9), p 2736–2744.

R. Vaßen, X. Cao, F. Tietz, and D. Basu, Zirconates as New Materials for Thermal Barrier Coatings, J. Am. Ceram. Soc., 2000, 83(8), p 2023–2028.

Y.J. Su, R.W. Trice, K.T. Faber, H. Wang, and W.D. Porter, Thermal Conductivity, Phase Stability, and Oxidation Resistance of Y3Al5O12(YAG)/Y2O3-ZrO2(YSZ) Thermal-Barrier Coatings, Oxid. Met., 2004, 61, p 253–271.

S.W. Jung, S. Park, and D. Choi, Efficient Drug Delivery Carrier Surface without Unwanted Adsorption Using Sulfobetaine Zwitterion, Adv. Eng. Mater., 2020, 23, p 2001433.

M. Gell, J. Wang, R. Kumar, J. Roth, and E.H. Jordan, Higher Temperature Thermal Barrier Coatings with the Combined Use of Yttrium Aluminum Garnet and the Solution Precursor Plasma Spray Process, J. Therm. Spray. Techn., 2018, 27(4), p 543–555.

G.R. Li, J.G. Yang, and C.X. Li, A Comprehensive Mechanism for the Sintering of Plasma-Sprayed Nanostructured Thermal Barrier Coatings, Ceram. Int., 2017, 43, p 9600–9615.

R. Kumar, E. Jordan, M. Gell, J. Roth, C. Jiang, J. Wang, and S. Rommel, CMAS Behavior of Yttrium Aluminum Garnet (YAG) and Yttria-Stabilized Zirconia (YSZ) Thermal Barrier Coatings, Surf. Coat. Tech., 2017, 327, p 126–138.

M.J. Liu, G. Zhang, Y.H. Lu, J.Q. Han, G.R. Li, C.X. Li, C.J. Li, and G.J. Yang, Plasma Spray-Physical Vapor Deposition toward Advanced Thermal Barrier Coatings: A Review, Rare. Met., 2020, 39(5), p 479–497.

R. Wellman, G. Whitman, and R.J. Nicholls, CMAS Corrosion of EB PVD TBCs: Identifying the Minimum Level to Initiate Damage, Int. J. Refract. Met. H., 2010, 28(1), p 124–132.

K. Stephan, J. Yang, and C.G. Levi, Thermo Mechanical Interaction of Thermal Barrier Coatings with Molten CaO-MgO-Al2O3-SiO2 (CMAS) Deposits, J. Am. Ceram. Soc., 2006, 89(10), p 3167–3175.

Y. Kuru, O. Savasir, S.Z. Nergiz, C. Oncel, and P. Aken, Yttrium Aluminum Garnet as a Scavenger for Ca and Si, J. Am. Ceram. Soc., 2008, 91(11), p 3663–3667.

Acknowledgments

The work was supported by National Natural Science Foundation of China (51901093, 52075234), Hongliu Distinguished Young Talent Support Program of Lanzhou University of Technology, Major Special Projects of Gansu Province (21ZD4WA017), the International Science and Technology Correspondent Program of Gansu province (17JR7WA017), and the program of “Science and Technology International Cooperation Demonstrative Base of Metal Surface Engineering along the Silk Road”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, C., Cheng, B., Zhang, Y. et al. Corrosion Behavior of Atmospheric Plasma-Sprayed YAG/8YSZ Double Ceramic-Layered Thermal Barrier Coatings in a Calcium–Magnesium–Alumino-Silicate Melt. J. of Materi Eng and Perform 31, 10205–10212 (2022). https://doi.org/10.1007/s11665-022-07014-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07014-w