Abstract

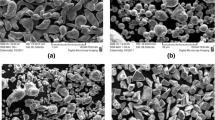

In this study, Al, Cu, Ni, Fe and Cr powders with equivalent molar ratio were taken and mechanically ball milled. Ball-milled AlCuNiFeCr was coated on the cleaned degreased Inconel-718 base material. Plasma Transferred Arc (PTA) method was adopted to get alloyed the coated particles on the base material. Phase formation, structural, elemental distribution in the alloyed region, enhancement of microhardness, wear behavior and wear mechanism of surface-modified Inconel-718 material were investigated. Result showed that the PTA treated sample possessed more BCC phases and large value of lattice distortion compared to the ball-milled powder. The top of the alloyed region mainly contained equiaxed crystals, inter-connected columnar dendrites, isolated inter-dendrites, secondary dendrite arm structure and Widmanstatten structure. The dendrites in the near interface region of the PTA alloyed region were gradually refined, became long and thin strips. The microhardness value of substrate, interface and alloyed surfaces were 348 ± 17.52 HV0.2, 643 ± 32.92 HV0.2 and 881 ± 44.64 HV0.2, respectively. The specific wear rate of PTA alloyed coatings was 0.0531 × 10–3 mm3/Nm which was less than that of Inconel-718 substrate (0.1711 ×10–3 mm3/Nm). The contact of the pin to the disc surface increased with the increase of the applied load from 40 N to 60 N. The COF of treated samples and Inconel-718 substrate at 40 N applied load with 1 m/s velocity were 0.28 and 0.46, respectively. Similarly, The COF at 60 N applied load with 0.8 m/s velocity were 0.42 and 0.81, respectively. Lower surface roughness was noticed on the treated worn-out samples due to less wear rate compared to the substrate material.

Similar content being viewed by others

Reference

S. Rani, A.K. Agrawal, and V. Rastogi, Failure Investigations of a First Stage Ni Based Super Alloy Gas Turbine Blade, Mater. Today: Proc., 2018, 5(1), p 477–486.

T. Wang, C. Wang, J. Li, L. Chai, Hu. Xing, Y. Ma, and Y. Huang, Microstructure and Wear Properties of Laser-Clad NiCo Alloy Coating on Inconel 718 Alloy, J. Alloy. Compd., 2021, 879, p 160412.

J. Liu, X. Zhang, Z. Cui, T. Ahmad, C. Wang, N. Hong, T. Liang, and B. Yang, Effects of Ultrasonic Surface Rolling Processing and Plasma Nitriding on the Fretting Wear Behavior of Inconel, Surf. Coat. Technol., 2020, 402, p 126312.

S.K. Sharma, K. Biswas, and J.D. Majumdar, Wear Behaviour of Electron Beam Surface Melted Inconel 718, Proc. Manufact., 2019, 35, p 866–873.

L. Fan, Y. Dong, H. Chen, L. Dong, and Y. Yin, Wear Properties of Plasma Transferred Arc Fe-based Coatings Reinforced by Spherical WC Particles, J. Wuhan Univ. Technol., 2019, 34(2), p 433–439.

J.B. Cheng, X.B. Liang, Z.H. Wang, and B.S. Xu, Formation and Mechanical Properties of CoNiCuFeCr High-Entropy Alloys Coatings Prepared by Plasma Transferred Arc Cladding Process, Plasma Chem. Plasma Process., 2013, 33(5), p 979–992.

T. Han, M. Xiao, Y. Zhang, and Y. Shen, Effect of Cr Content on Microstructure and Properties of Ni-Ti-xCr Coatings by Laser Cladding, Int. J. Light and Elect. Optics, 2019, 179, p 1042–1048.

H. Li, X. Zhou, X. Lu, and Y. Wang, Effect of La on-Arc Erosion Behaviors and Oxidation Resistance of Cu Alloys, T. Nonferr. Metal. Soc., 2017, 27, p 102–109.

Q. Wu and J. Zhang, Corrosion Behavior of Laser-Clad Cu-9Ni-6Sn Coating, Surf. Coat. Technol., 2018, 349, p 1117–1129.

Y. Zhang, T.F. Han, M. Xiao, and Y.F. Shen, Effect of Iron Content on Microstructure and Properties of FexNi2Co2CrTiNb High-entropy Alloy Coating, Optik, 2020, 204, p 164–168. https://doi.org/10.1016/j.ijleo.2020.164168

M. Sudheer, P. Ravikantha, K. Raju, and B. Thirumaleshwara, Modeling and Analysis for Wear Performance in Dry Sliding of Epoxy/Glass/PTW Composites Using Full Factorial Techniques, ISRN Tribology, 2013 https://doi.org/10.5402/2013/624813

D. Lu and S. Wei, Effect of Grinding Aids on Producing Ultrafine Particles, Adv. Powder Technol., 1992, 3, p 47–53. https://doi.org/10.1016/S0921-8831(08)60688-3

F. Hadef, A. Otmani, A. Djekoun, and J.M. Greneche, Structural and microstructural study of nanostructured Fe50Al40Ni10 powders produced by mechanical alloying, Mater. Charact., 2011, 62, p 751–759.

J.M. Wu, S.J. Lin, J.W. Yeh, S.K. Chen, Y.S. Huang, and H.C. Chen, Adhesive wear behavior of AlxCoCrCuFeNi high-entropy alloys as a function of aluminum content, Wear, 2006, 261, p 513–519. https://doi.org/10.1016/j.wear.2005.12.008

W.R. Wang, W.L. Wang, S.C. Wang, Y.C. Tsai, C.H. Lai, and J.W. Yeha, Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high entropy alloys, Intermetallics, 2012, 26, p 44–51. https://doi.org/10.1016/j.intermet.2012.03.005

D. Li, Z. Shu-ling, L. Wei-bing, G. Gui-hong, and Z. Yong, Superelasticity of Cu–Ni–Al Shape-Memory Fibers Prepared by Melt Extraction Technique, Int J Min, Metall Mater, 2016, 23, p 928.

Y. Lin, B. Yao, Z. Zhang, Y. Li, Y. Sohn, J.M. Schoenung, and E.J. LaVernia, Strain Energy During Mechanical Milling: Part I. Mathematical Modeling, Mater. Trans. A., 2012, 43, p 4247–4257. https://doi.org/10.1007/s11661-012-1223-4

Z. Adabavazeh, F. Karimzadeh, and M.H. Enayati, Thermodynamic Analysis of (Ni, Fe) 3Al Formation by Mechanical Alloying, Chem. Thermodyn., 2012, 54, p 406–411. https://doi.org/10.1016/j.jct.2012.05.027

T. Ghosh, A.P. Jena, and A. Mookerjee, Effects of Chemical Ordering and Composition on the Magnetic Properties of Disordered FeAl Alloys, J. Alloys Compd., 2015, 639, p 583–587. https://doi.org/10.1016/j.jallcom.2015.03.186

A. Cherif, T. Bachaga, J. Saurina, J.J. Sunol, M. Khitouni, and T. Makhlouf, Morphology and Structure Effect of Ti Additive on the Solid-State Reaction Between Ni and Al Powders During Mechanical Alloying, Int. J. Adv. Manuf. Technol., 2016, 86, p 2937–2943. https://doi.org/10.1007/s00170-016-8407-9

H. Liu, P.J. Chen, H.F. Yang, J.B. Hao, X.H. Tian, X.L. He, and G. Yu, Processing Window and Microstructure of NiCoCrAlY Coating Deposited on Cast IRON Using Multilayer Laser Cladding, J. Spectro., 2019, 2019, p 1–15. https://doi.org/10.1155/2019/9308294

J.H. Yao, J. Zhang, G.L. Wu, L. Wang, Q.L. Zhang, and R. Liu, Microstructure and Wear Resistance of Laser Cladded Composite Coatings Prepared from pre-alloyed WCNiCrMo Powder with Different Laser Spots, Opt. Laser Technol., 2018, 101, p 520–530. https://doi.org/10.1016/j.optlastec.2017.12.007

L.Z. Zhao, X.Y. Jiang, M.J. Zhao, and J. Zhang, Phase-field Simulation of Dendrite Growth of Magnesium Alloy Under Non-isothermal Solidification, Adv Mater. Res., 2014, 848, p 231–235. https://doi.org/10.4028/www.scientific.net/AMR.848.231

T.W. Dipak, K.P. Chinmaya, P. Ritesh, and M. Manoj, NiTi Coating on Ti-6Al-4V alloy by TIG Cladding Process for Improvement of Wear Resistance: Microstructure Evolution and Mechanical Performances, J. Mater. Process. Technol., 2018, 262, p 551–561.

Y. Qiu, S. Thomas, D. Fabijanic, A.J. Barlow, H.L. Fraser, and N. Birbilis, Microstructural Evolution, Electrochemical and Corrosion Properties of AlxCoCrFeNiTiy High Entropy Alloys, Mater. Des., 2019, 170, p 107698. https://doi.org/10.1016/j.matdes.2019.107698

W. Fei, Yu. Huijun, and C. Chuanzhong, Effect of Processparameters on the Microstructure Evolution and Wearproperty of the Laser Cladding Coatings on Ti-6Al-4V Alloy, J. Alloys Compd., 2017, 692, p 989–996.

N. Jeyaprakash and C.-H. Yang, Microstructure and Wear Behaviour of SS420 Micron Layers on Ti–6Al–4V Substrate Using Laser Cladding Process, Trans. Indian Inst. Metals, 2020, 73(6), p 1527–1533.

M. Danek, F. Fernandes, A. Cavaleiro, and T. Polcar, Influence of Cr Additions on the Structure and Oxidation Resistance of Multilayered TiAlCrN Films, Surf. Coat. Technol., 2017, 313, p 158–167.

J.J. Zhang, Y.M. Gao, J.D. Xing, S.Q. Ma, D.W. Yi, and J.B. Yan, Effects of Chromium Addition on Microstructure and Abrasion Resistance of Fe–B Cast Alloy, Tribol. Lett., 2011, 44, p 31–39.

N. Jeyaprakash and C.-H. Yang, Improvement of Tribo-mechanical Properties of Directionally Solidified CM-247 LC Nickel-Based Super Alloy Through Laser Material Processing, Int. J. Adv. Manufact. Technol., 2020, 106, p 4805–4814.

J.M. Wu, S.J. Lin, J.W. Yeh, S.K. Chen, Y.S. Huang, and H.C. Chen, Adhesive Wear Behavior of AlxCoCrCuFeNi High-Entropy, Wear, 2006, 261, p 513–519. https://doi.org/10.1016/j.wear.2005.12.008

Y. Yu, W. Liu, T. Zhang, J. Li, J. Wang, H. Kou, and J. Li, Microstructure and Tribological Properties of AlCoCrFeNiTi0.5, High-Entropy Alloy in Hydrogen Peroxide Solution, Metall. Mater. Trans. A, 2014, 45, p 201–207.

J. Joseph, N. Haghdadi, K. Shamlaye, P. Hodgson, M. Barnett, and D. Fabijanic, The Sliding Wear Behaviour of CoCrFeMnNi and AlxCoCrFeNi High Entropy Alloys at Elevated Temperatures, Wear, 2019, 428–429, p 32–44.

Acknowledgments

We are grateful for the support from the Ministry of Science and Technology, Taiwan for providing the financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jeyaprakash, N., Prabu, G. & Yang, CH. The Influence of Different Phases on the Microstructure and Wear of Inconel-718 Surface Alloyed with AlCuNiFeCr Hard Particles Using Plasma Transferred Arc. J. of Materi Eng and Perform 31, 9921–9934 (2022). https://doi.org/10.1007/s11665-022-06982-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06982-3