Abstract

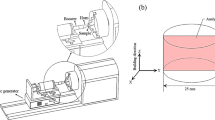

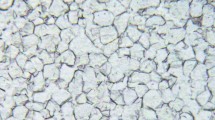

With the aim of controlling fatigue and elastic behaviors, the specimens of alpha-Ti were produced using the powder metallurgy (PM) technique and then subjected to plastic deformation induced by multiple sliding impacts by the specimen surface produced at ultrasonic impact treatment (UIT). The dependencies of residual porosity of the PM Ti specimens on the powder particle size, hydrogen content, compact pressures, and vacuum sintering temperature are analyzed. The diminishment in the elastic properties with increasing porosity is assessed. The effect of the UIT process on the stress-controlled fatigue response of the PM Ti is studied. The microstructure of the UIT-processed specimens was observed by XRD, LOM, TEM, and SEM techniques. The UIT process leads to approx. four times decrease in the surface roughness (Ra = 0.34 μm) parameter, three times increase in microhardness (HV ≈ 5 GPa), and forms compressive stresses of ~ 420 MPa. After UIT, fatigue strength was increased by about 36% on the base of 107 cycles, and the lifetime was prolonged by two orders of magnitude at the applied stress amplitude of 300 MPa. Cross sections of the UIT-processed specimens were revealed to have a multilayer structure comprising the outmost layer of ~ 30 to 50 μm thick contained nanoscale randomly oriented grains of 5-30 nm in size, intermediate condensed (pores free) layer of ~ 150 to 200 μm thick, and porous core. The UIT process combined with the PM route is concluded to be an effective technique to achieve superior fatigue behaviors of PM-titanium products both in LCF and HCF regimes owing to (1) the ultrafine-grained condensed sub-surface layer with inhibited strain localization and slowed down crack propagation and (2) the formation of the hardened top-surface layer with nanocrystalline structure, respectively.

Similar content being viewed by others

References

G. Lütjering and J.C. Williams, Gysler, Microstructure and of titanium Mechanical Properties Alloys, Microstructure and Properties of Materials. J.C.M. Li Ed., World Scientific Publ and Imperial College Press, 2000, p 1–77

M. Geetha, A.K. Singh, R. Asokamani and A.K. Gogia, Ti Based Biomaterials, the Ultimate Choice for Orthopaedic Implants: A Review, Progress, Mater. Sci., 2009, 54, p 397–425. https://doi.org/10.1016/j.pmatsci.2008.06.004

X. Liu, P.K. Chu and C. Ding, Surface Modification of Titanium, Titanium Alloys, and Related Materials for Biomedical Applications, Mater. Sci. Eng. R, 2004, 47, p 49–121. https://doi.org/10.1016/j.mser.2004.11.001

H.J. Rack and J.I. Qazi, Titanium Alloys for Biomedical Applications, Mater. Sci. Eng. C, 2006, 26, p 1269–1277. https://doi.org/10.1016/j.msec.2005.08.032

E. Alabort, D. Barba and R.C. Reed, Design of Metallic Bone by Additive Manufacturing, Scr. Mater., 2019, 164, p 110–114. https://doi.org/10.1016/j.scriptamat.2019.01.022

F.H. Froes, S.J. Mashl, V.S. Moxson, J.C. Hebeisen and V.A. Duz, The Technologies of Titanium Powder Metallurgy, JOM, 2004, 56(11), p 46–48. https://doi.org/10.1007/s11837-004-0252-x

A.A. Hidalgo, R. Frykholm, T. Ebel and F. Pyczak, Powder Metallurgy Strategies to Improve Properties and Processing of Titanium Alloys: A Review, Adv. Eng. Mater., 2017 https://doi.org/10.1002/adem.201600743

K. Pałka and R. Pokrowiecki, Porous Titanium Implants: A Review, Adv. Eng. Mater., 2018 https://doi.org/10.1002/adem.201700648

O.M. Ivasishin, V.M. Anokhin, A.N. Demidik and D.G. Savvakin, Cost-Effective Blended Elemental Powder Metallurgy of Titanium Alloys for Transportation Application, Key Eng. Mater., 2000, 188, p 55–62. https://doi.org/10.4028/www.scientific.net/KEM.188.55

K.L.S. Goi, D.L. Butler, A.E.W. Jarfors, J.M.S. Yong and D.C.S. Lim, Elastic Modulus of Sintered Porous Ti–Si–Zr, Using Activation by Ti–Si Mechanically Alloyed Powder and TiH2 Powder, Mater. Sci. Eng. A, 2008, 475, p 45–51. https://doi.org/10.1016/j.msea.2007.02.129

D.-W. Lee, H.-S. Lee, J.-H. Park, S.-M. Shin and J.-P. Wang, Sintering of Titanium Hydride Powder Compaction, Procedia Manuf., 2015, 2, p 550–557. https://doi.org/10.1016/j.promfg.2015.07

P.E. Markovsky, M. Ikeda, D.G. Savvakin and O.O. Stasyuk, Microstructure and Properties of New Ti–Al–Fe–Cr Transition Class Alloy Produced by Blended Elemental Powder Metallurgy Using TiH2 and Master Alloy, Metallogr. Microstruct. Anal., 2018, 7, p 184–193. https://doi.org/10.1007/s13632-018-0427-4

F.H. Froes, D. Eylon, Powder Metallurgy of Titanium Alloys: A Review, in: F.H. Froes, D. Eylon, and H.B. Bomberger (Eds.), Titanium Technology: Present Status and Future Trends, Warrendale, 1985, pp. 49–59, https://doi.org/10.1179/095066090790323984

A.I. Dekhtyar, I.V. Moiseeva and D.G. Savvakin, Tensile Deformation and Fracture of Alpha Plus Beta-Titanium Alloys Synthesized by Powder Metallurgy, Metallofiz. Noveish. Tekhnol., 2013, 35, p 889–908.

A.I. Dekhtyar, B.N. Mordyuk, D.G. Savvakin, V.I. Bondarchuk, I.V. Moiseeva and N.I. Khripta, Enhanced Fatigue Behavior of Powder Metallurgy Ti–6Al–4V Alloy by Applying Ultrasonic Impact Treatment, Mater. Sci. Eng. A, 2015, 641, p 348–359. https://doi.org/10.1016/j.msea.2015.06.072

J. Shen, B. Chen, J. Umeda and K. Kondoh, Microstructure and Mechanical Properties of CP-Ti Fabricated Via Powder Metallurgy with Non-Uniformly Dispersed Impurity Solutes, Mater. Sci. Eng. A, 2018, 716, p 1–10. https://doi.org/10.1016/j.msea.2018.01.031

I.-H. Oh, N. Nomura, N. Masahashi and S. Hanada, Mechanical Properties of Porous Titanium Compacts Prepared by Powder Sintering, Scr. Mater., 2003, 49, p 1197–1202. https://doi.org/10.1016/j.scriptamat.2003.08.018

H.W. Jeong, S.E. Kim, Y.T. Hyun, Y.T. Lee and J.K. Park, Microstructures and Elastic Moduli of Binary Titanium Alloys Containing Biocompatible Alloying Elements, Mater. Sci. Forum, 2005, 475–479, p 2291–2294. https://doi.org/10.4028/www.scientific.net/MSF.475-479.2291

D. Kuroda, M. Niinomi, M. Morinaga, Y. Kato and T. Yashiro, Design and Mechanical Properties of New β Type Titanium Alloys for Implant Materials, Mater. Sci. Eng. A, 1998, 243, p 244–249. https://doi.org/10.1016/S0921-5093(97)00808-3

F.A. Shah, M. Trobos, P. Thomsen and A. Palmquist, Commercially Pure Titanium (cp-Ti) Versus Titanium Alloy (Ti6Al4V) Materials as Bone Anchored Implants: Is One Truly Better Than the Other?, Mater. Sci. Eng. C, 2016, 62, p 960–966. https://doi.org/10.1016/j.msec.2016.01.032

L. Wagner, Mechanical Surface Treatments on Titanium, Aluminum and Magnesium Alloys, Mater. Sci. Eng. A, 1999, 263, p 210–216. https://doi.org/10.1016/S0921-5093(98)01168-X

O. Unal, A.C. Karaoglanli, R. Varol and A. Kobayashi, Microstructure Evolution and Mechanical Behavior of Severe Shot Peened Commercially Pure Titanium, Vacuum, 2014, 110, p 202–206. https://doi.org/10.1016/j.vacuum.2014.08.004

K.Y. Zhu, A. Vessel, F. Brisset, K. Lu and J. Lu, Nanostructure Formation Mechanism of α-Titanium Using SMAT, Acta Mater., 2004, 52, p 4101–4110. https://doi.org/10.1016/j.actamat.2004.05.023

Y. Yin, W. Xu, Q. Sun, L. Xiao and J. Sun, Deformation And Fracture Behavior of Commercially Pure Titanium with Gradient Nano-to-Micron-Grained Surface Layer, Trans. Nonferrous Met. Soc. China, 2015, 25, p 738–747. https://doi.org/10.1016/S1003-6326(15)63659-7

W.L. Li, N.R. Tao and K. Lu, Fabrication of a Gradient Nano-Micro-Structured Surface Layer on Bulk Copper by Means of a Surface Mechanical Grinding Treatment, Scripta Mater., 2008, 59, p 546–549. https://doi.org/10.1016/j.scriptamat.2008.05.003

S. Kumar, K. Chattopadhyay and V. Singh, Effect of Ultrasonic Shot Peening on LCF Behavior of the Ti–6Al–4V Alloy, J. Alloys Comp., 2017, 724, p 187–197. https://doi.org/10.1016/j.jallcom.2017.07.014

L. Zhu, Y. Guan, Y. Wang, Z. Xie, J. Lin and J. Zhai, Influence of Process Parameters of Ultrasonic Shot Peening on Surface Roughness and Hydrophilicity of Pure Titanium, Surf. Coat. Technol., 2017, 317, p 38–53. https://doi.org/10.1016/j.surfcoat.2017.03.044

P.E. Markovs’kyi, V.K. Pishchak, B.N. Mordyuk and P.N. Okrainets’, Improvement of the Fatigue Characteristics of VT1-0 Titanium Alloy by the Surface Mechanical and Rapid Thermal Treatment, Mater. Sci., 2006, 42, p 376–383. https://doi.org/10.1007/s11003-006-0092-7

B.N. Mordyuk and G.I. Prokopenko, Fatigue Life Improvement of α-Titanium by Novel Ultrasonically Assisted Technique, Mater. Sci. Eng. A, 2006, 437, p 396–405. https://doi.org/10.1016/j.msea.2006.07.119

M.O. Vasylyev, B.M. Mordyuk, D.V. Pavlenko and L.F. Yatsenko, Ultrasonic Impact Processing of Surface Layer of the BT1-0 Titanium in a Submicrocrystalline State, Metallofiz. Noveishie Tekhnol., 2015, 37, p 121–134.

A.V. Panin, M.S. Kazachenok, A.I. Kozelskaya, R.R. Balokhonov, V.A. Romanova, O.B. Perevalova and Yu.I. Pochivalov, The Effect of Ultrasonic Impact Treatment on the Deformation Behavior of Commercially Pure Titanium under Uniaxial Tension, Mater. Design, 2017, 117, p 371–381. https://doi.org/10.1016/j.matdes.2017.01.006

Y.F. Liu, Y. Cao, H. Zhou, X.F. Chen, Y. Liu, L. Xiao, X.W. Huan, Y.H. Zhao and Y.T. Zhu, Mechanical Properties and Microstructures of Commercial Purity Aluminum Processed by Rotational Accelerated Shot Peening Plus Cold Rolling, Adv. Eng. Mater., 2020, 22, p 1900478. https://doi.org/10.1002/adem.201900478

Y.F. Liu, Y.T. Zang, Y. Cao, W. Liu, Q.Z. Mao, H. Zhou, W. Jiang, Y.H. Zhao and Y.T. Zhu, Significance of Surface Layer Integrity for Sustaining the Ductility of Gradient-Structured Nickel, Mater. Lett., 2021, 303, 130491. https://doi.org/10.1016/j.matlet.2021.130491

J. Shen, B. Chen, X. Ye, H. Imai, J. Umeda and K. Kondoh, The Formation of Bimodal Multilayered Grain Structure and its Effect on the Mechanical Properties of Powder Metallurgy Pure Titanium, Mater. Design, 2017, 116, p 99–108. https://doi.org/10.1016/j.matdes.2016.12.004

H. Toda, K. Minami, K. Koyama, K. Ichitani, M. Kobayashi, K. Uesugi and Y. Suzuki, Healing Behavior of Preexisting Hydrogen Micropores in Aluminum Alloys During Plastic Deformation, Acta Mater., 2009, 57, p 4391–4403. https://doi.org/10.1016/j.actamat.2009.06.012

D.A. Lesyk, S. Martinez, B.N. Mordyuk, V.V. Dzhemelinskyi, A. Lamikiz and G.I. Prokopenko, Post-processing of the Inconel 718 Alloy Parts Fabricated by Selective Laser Melting: Effects of Mechanical Surface Treatments on Surface Topography, Porosity, Hardness and Residual Stress, Surf. Coat. Technol., 2020, 381, 125136. https://doi.org/10.1016/j.surfcoat.2019.125136

D.H. Savvakin, M.M. Humenyak, M.V. Matviichuk and O.H. Molyar, Role of Hydrogen in the Process of Sintering of Titanium Powders, Mater. Sci., 2012, 47, p 651–661. https://doi.org/10.1007/s11003-012-9440-y

B.B. Panigrahi, Sintering Behaviour of Ti–2Ni and Ti–5Ni Elemental Powders, Mater. Lett., 2007, 61, p 152–155. https://doi.org/10.1016/j.matlet.2006.04.025

H.-W. Liu, D.P. Bishop and K.P. Plucknett, A Comparison of Ti–Ni and Ti-Sn Binary Alloys Processed Using Powder Metallurgy, Mater. Sci. Eng. A, 2015, 644, p 392–404. https://doi.org/10.1016/j.msea.2015.07.085

N. Chawla and X. Deng, Microstructure and Mechanical Behavior of Porous Sintered Steels, Mater. Sci. Eng. A, 2005, 390, p 98–112. https://doi.org/10.1016/j.msea.2004.08.046

N. Ramakrishnan and V.S. Arunachalam, Effective Elastic Moduli of Porous Ceramic Materials, J. Am. Ceram. Soc., 1993, 76, p 2745–2752. https://doi.org/10.1111/j.1151-2916.1993.tb04011.x

B.N. Mordyuk, M.O. Iefimov, G.I. Prokopenko, T.V. Golub and M.I. Danylenko, Structure, Microhardness and Damping Characteristics of Al Matrix Composite Reinforced with AlCuFe or Ti Using Ultrasonic Impact Peening, Surf. Coat. Technol., 2010, 204, p 1590–1598. https://doi.org/10.1016/j.surfcoat.2009.10.009

Y.K. Gao, Improvement of Fatigue Property in 7050–T7451 Aluminum Alloy by Laser Peening and Shot Peening, Mater. Sci. Eng. A, 2011, 528, p 3823–3828. https://doi.org/10.1016/j.msea.2011.01.077

Y.K. Gao, X.B. Li, Q.X. Yang and M. Yao, Influence of Surface Integrity on Fatigue Strength of 40CrNi2Si2MoVA Steel, Mater. Let., 2007, 61, p 466–469. https://doi.org/10.1016/j.matlet.2006.04.089

S. Wang, Y. Li, M. Yao and R. Wang, Fatigue Limits of Shot-Peened Metals, J. Mater. Proc. Technol., 1998, 73, p 57–63. https://doi.org/10.1016/S0924-0136(97)00212-4

A. Vinogradov, Fatigue Limit and Crack Growth in Ultra-Fine Grain Metals Produced by Severe Plastic Deformation, J. Mater. Sci., 2007, 42, p 1797–1808. https://doi.org/10.1007/s10853-006-0973-z

T. Roland, D. Retraint, K. Lu and J. Lu, Fatigue Life Improvement Through Surface Nanostructuring of Stainless Steel by Means of Surface Mechanical Attrition Treatment, Scr. Mater., 2006, 54, p 1949–1954. https://doi.org/10.1016/j.scriptamat.2006.01.049

B.N. Mordyuk, G.I. Prokopenko, M.A. Vasylyev and M.O. Iefimov, Effect of Structure Evolution Induced by Ultrasonic Peening on the Corrosion Behavior of AISI-321 Stainless Steel, Mater. Sci. Eng. A, 2007, 458, p 253–261. https://doi.org/10.1016/j.msea.2006.12.049

B.N. Mordyuk, O.P. Karasevskaya, G.I. Prokopenko and N.I. Khripta, Ultrafine-Grained Textured Surface Layer on Zr–1% Nb Alloy Produced by Ultrasonic Impact Peening for Enhanced Corrosion Resistance, Surf. Coat. Technol., 2012, 210, p 54–61. https://doi.org/10.1016/j.surfcoat.2012.08.063

M.A. Vasylyev, B.N. Mordyuk, S.I. Sidorenko, S.M. Voloshko and A.P. Burmak, Influence of Microstructural Features and Deformation-Induced Martensite on Hardening of Stainless Steel by Cryogenic Ultrasonic Impact Treatment, Surf. Coat. Technol., 2018, 343, p 57–68. https://doi.org/10.1016/j.surfcoat.2017.11.019

M.A. Vasylyev, B.N. Mordyuk, V.P. Bevz, S.M. Voloshko and O.B. Mordiuk, Ultrasonically Nanostructured Electric-Spark Deposited Ti Surface Layer on Ti6Al4V Alloy: Enhanced Hardness and Corrosion Resistance, Int. J. Surf. Sci. Eng., 2020, 14(1), p 1–15. https://doi.org/10.1504/IJSURFSE.2020.10027541

B.N. Mordyuk, O.P. Karasevskaya and G.I. Prokopenko, Structurally Induced Enhancement in Corrosion Resistance of Zr–2.5% Nb Alloy in Saline Solution by Applying Ultrasonic Impact Peening, Mater. Sci. Eng. A, 2013, 559, p 453–461. https://doi.org/10.1016/j.msea.2012.08.125

L. Zhu, Y. Guan, J. Lin, J. Zhai and Z. Xie, A Nanocrystalline-Amorphous Mixed Layer Obtained by Ultrasonic Shot Peening on Pure Titanium at Room Temperature, Ultrasonics Sonochem., 2018, 47, p 68–74. https://doi.org/10.1016/j.ultsonch.2018.04.017

P.J. Hsieh, Y.P. Hung and J.C. Huang, Transformation into Nanocrystalline or Amorphous Materials in Zr-X Binary Systems Using ARB Route, Scripta Mater., 2003, 49, p 173–178. https://doi.org/10.1016/S1359-6462(03)00207-0

H. Jia, K. Marthinsen and Y. Li, Revealing Abnormal 112–1 Twins in Commercial Purity Ti Subjected to Split Hopkinson Pressure Bar, J. Alloys Comp., 2019, 783, p 513–523. https://doi.org/10.1016/j.jallcom.2018.12.092

A.I. Dekhtyar, V.I. Bondarchuk, V.V. Nevdacha and A.V. Kotko, The Effect of Microstructure on Porosity Healing Mechanism of Powder near-β Titanium Alloys under Hot Isostatic Pressing in α+ β-Region: Ti-10V-2Fe-3Al, Mater. Charact., 2020, 165, 110393. https://doi.org/10.1016/j.matchar.2020.110393

M.A. Vasylyev, S.P. Chenakin and L.F. Yatsenko, Ultrasonic Impact Treatment Induced Oxidation of Ti6Al4V Alloy, Acta Mater., 2016, 103, p 761–774. https://doi.org/10.1016/j.actamat.2015.10.041

S. Firstov, V. Kulikovsky, T. Rogul and R. Ctvrtlik, Effect of Small Concentrations of Oxygen and Nitrogen on the Structure and Mechanical Properties of Sputtered Titanium Films, Surf. Coat. Technol., 2012, 206, p 3580–3585. https://doi.org/10.1016/j.surfcoat.2012.02.039

J. Guo, M.J. Duarte, Y. Zhang, A. Bachmaier, C. Gammer, G. Dehm, R. Pippan and Z. Zhang, Oxygen-Mediated Deformation and Grain Refinement in Cu-Fe Nanocrystalline Alloys, Acta Mater., 2019, 166, p 281–293. https://doi.org/10.1016/j.actamat.2018.12.040

J.F. Nie, Y.F. Liu, F. Wang, H. Zhou, Y. Cao, X.F. Liu, X.H. An, X.Z. Liao, Y.T. Zhu and Y.H. Zhao, Key Roles of Particles in Grain Refinement and Material Strengthening for an Aluminum Matrix Composite, Mater. Sci. Eng. A, 2021, 801, 140414. https://doi.org/10.1016/j.msea.2020.140414

B.N. Mordyuk, S.M. Voloshko, V.I. Zakiev, A.P. Burmak and V.V. Mohylko, Enhanced Resistance of Ti6Al4V Alloy to High-Temperature Oxidation and Corrosion by Forming Alumina Composite Coating, J. Mater. Eng. Perform., 2021, 30, p 1780–1795. https://doi.org/10.1007/s11665-021-05492-y

I.P. Shatskyi, L.Y. Ropyak and M.V. Makoviichuk, Strength Optimization of a Two-Layer Coating for the Particular Local Loading Conditions, Strength Mater, 2016, 48, p 726–730. https://doi.org/10.1007/s11223-016-9817-5

V.V. Knysh, B.N. Mordyuk, G.I. Prokopenko and S.A. Solovey, Increasing Corrosion Fatigue of Welded Joints of Steel 15KhSND with Construction Defects by Electric Discharge Surface alloying and High Frequency Mechanical Impact, Metallofiz. Noveishie Tekhnol., 2019, 41, p 1631–1652. https://doi.org/10.15407/mfint.41.12.1631

V. Trush, V. Fedirko and A. Luk’yanenko, Surface Treatment of Titanium Alloys in Oxygen-Containing Gaseous Medium, Titanium Alloys: Novel Aspects of their Manufacturing and Processing. M. Motyka Ed., IntechOpen, 2019, p 1–27

S. Raynova, F. Yang and L. Bolzoni, The Effect of Thermomechanical Treatments on the Properties of Powder Metallurgy Ti–5Fe Alloy, Mater. Sci. Eng. A, 2021, 801, 140389. https://doi.org/10.1016/j.msea.2020.140389

N.G. Turner and W.T. Roberts, Fatigue Behavior of Titanium, Trans. AIME, 1968, 242, p 1223–1230.

A.Yu. Vinogradov, V.V. Stolyarov, S. Hashimoto and R.Z. Valiev, Cyclic Behavior of Ultrafine-Grain Titanium Produced by Severe Plastic Deformation, Mater. Sci. Eng. A, 2001, 318, p 163–173. https://doi.org/10.1016/S0921-5093(01)01262-X

K. Takahashi and E. Sato, Influence of Surface Treatments on Fatigue Strength of Ti6Al4V Alloy, Mater. Trans., 2010, 51(4), p 694–698. https://doi.org/10.2320/matertrans.MA200901

Acknowledgments

This work was supported by the National Academy of Sciences of Ukraine [Grant Numbers 94/14-H, 0119U001167, 0120U101261].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mordyuk, B.N., Dekhtyar, A.I., Savvakin, D.G. et al. Tailoring Porosity and Microstructure of Alpha-Titanium by Combining Powder Metallurgy and Ultrasonic Impact Treatment to Control Elastic and Fatigue Properties. J. of Materi Eng and Perform 31, 5668–5678 (2022). https://doi.org/10.1007/s11665-022-06633-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06633-7