Abstract

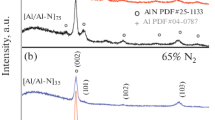

[CoN/AlN]n multilayer coatings with different bilayer numbers (n = 10, 20 and 30) were developed, showing an interesting evolution in the mechanical properties and tribological behavior. These coatings were deposited by pulsed laser deposition technique with a Nd: YAG laser (λ = 1064 nm) on Silicon (100) and AISI 302 steel substrates. The structural and chemical composition analysis was performed by (XRD) and (XPS), showing characteristic phases and the stoichiometry of AlN (111) and CoN (200) materials. The surface morphology by (AFM) presented a reduction in grain size and roughness as a function of the bilayer number. The mechanical evaluation found an increase of 40% in the hardness and 19.4% in the elastic modulus when comparing [CoN/AlN]30 to the cobalt nitride (CoN) single layer. The tribological analysis evidenced the values of 0.33 for the friction coefficient and 57 N for the critical load at which the adhesive failure of the coatings (LC2) appeared. The mechano-tribological results found in these transition metals-based multilayer nitrides open a possibility of future applications in mechanical devices that require high demands in service conditions due to the high mechanical performance observed in the [CoN/AlN]n multilayers.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Z.G. Wu, G.A. Zhang, M.X. Wang, X.Y. Fan, P.X. Yan and T. Xu, Structure and Mechanical Properties of Al/AlN Multilayer with Different AlN Layer Thickness, Appl. Surface Sci., 2006, 253(I–5), p 2733–2738.

W.F. Piedrahita, L. Emerson Coy, C. Amaya, J.C. Irantzu Llarena and L. Yate. Caicedo, Influence of the Negative R.F. Bias Voltage on the Structural, Mechanical and Electrical Properties of Hf-C-N Coatings, Surface Coat. Technol., 2016, 286, p 251–255.

C.I. Zandalazini, M.I. Oliva and J.C. Ferrero, Pulsed Laser Deposition: Development And implementation of the Technique of Grown of Multilayers, ANALES AFA, 2016, 27, p 40–46.

M. Matsuoka, K. Ono and T. Inukai, Magnetic Properties of Cobalt Nitride Thin Films, Phys. Lett., 1986, 49, p 977.

K. Oda, T. Yoshio and K. Oda, Preparation of Co-N Films by rf-Sputtering, J. Mater. Sci., 1987, 22, p 2729–2733.

J. Shiung Fang, L. Yang, C.-S. Hsu, G.-S. Chen, Y. Wei Lin and G.S. Chen, Phase Transition Behavior of Reactive Sputtering Deposited Co-N Thin Films Using Transmission Electron Microscopy, J. Vacuum Sci. Technol. A, 2004, 22, p 698.

A. Houari, S.F. Matar and M.A. Belkhir, DFT Study of Magneto-Volume Effects in Iron and Cobalt Nitrides, J. Magn. Magn. Mater., 2010, 322(6), p 658–660.

R. Gupta, N. Pandey, A. Tayal and M. Gupta, Phase formation, Thermal Stability and Magnetic Moment of Cobalt Nitride Thin Films, AIP Adv., 2015, 5, p 097131.

J.A. Pérez Taborda, J.C. Caicedo, M. Grisales, W. Saldarriaga and H. Riascos, Deposition Pressure Effect on Chemical, Morphological and Optical Properties of Binary Al-Nitrides, Optics Laser Technol., 2015, 69, p 92–103.

V. Moraes, H. Riedl, R. Rachbauer, S. Kolozsvári, M. Ikeda, L. Prochaska, S. Paschen and P.H. Mayrhofer, Thermal Conductivity and Mechanical Properties of AlN-Based Thin Films, J. Appl. Phys., 2016, 119, p 225304.

Y. Chiu, Ch. Yo Yen, M.-S. Chiang, G.J. Chen, Sh.R. Jian, C. Wang and H.L. Kao, Mechanical Properties and Fracture Toughness of AlN Thin Films Deposited Using Helicon Sputtering, Nanosci. Nanotechnol. Lett., 2017, 9(4), p 562–566.

A. Iqbal and F. Mohd-Yasin, Reactive Sputtering of Aluminum Nitride (002) Thin Films for Piezoelectric Applications: A Review, Sensors, 2018, 18, p 1797.

E. lmeriÖsterlund, J. Kinnunen, V. Rontu, A. Torkkeli and M. Paulasto-Kröckel, Mechanical Properties and Reliability of Aluminum Nitride Thin Films, J. Alloys Compounds, 2019, 772(25), p 306–313.

E. Alfaro-Pérez, F. Chiñas-Castillo, F.J. Flores-Ruiz, R. Alavez-Ramirez, M. Caballero-Caballero and J. Lara-Romero, Friction and Wear Behavior of Multilayer [Al/AlN]n Coatings Deposited on AISI52100 Steel, Prot. Met. Phys. Chem. Surf., 2019, 55, p 527–534.

C. Appleget and A.M. Hodge, Optical and Mechanical Characterization of Sputtered AlN/Ag Multilayer Films, Adv. Eng. Mater., 2019, 21(5), p 18012.

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7, p 1564–1583.

ASTM G99-17, Standard test method for wear testing with a pin-on-disk apparatus. 1–6. (2017)

ASTM G171-03, Standard test method for scratch hardness of materials using a diamond stylus. 1–7 (2017)

L. Rosenberger, R. Baird, E. McCullen, G. Auner and G. Shreve, XPS Analysis of Aluminum Nitride Films Deposited by Plasma Source Molecular Beam Epitaxy, Surf. Interface Anal., 2008, 40(9), p 1254–1261.

P. Motamedi and K. Cadien, XPS Analysis of AlN Thin Films Deposited by Plasma Enhanced Atomic Layer Deposition, Appl. Surf. Sci., 2014, 315, p 104–109.

H. Li, G.M. Cai and W.J. Wang, Room Temperature Luminescence and Ferromagnetism of AlN:Fe, AIP Adv., 2016, 6, p 065025.

R. Dallaev, D. Sobola, P. Tofel, L. Škvarenina and P. Sedlák, Aluminum Nitride Nanofilms by Atomic Layer Deposition Using Alternative Precursors Hydrazinium Chloride and Triisobutylaluminum, Coatings., 2020, 10, p 954–968.

S. Il Kim, S. Ryull Lee, J. Ho and B. Tae Ahn, Epitaxial Growth of CoSi 2 Layer on a Si 100 Substrate Using a CoN x Interlayer Deposited by Reactive Sputtering, Korean J. Mater. Res., 2006, 16(1), p 30.

V.N. Antsiferov, V.G. Gilyov and V.I. Karmanov, IR-spectra and Phases Structure of Sialons. Vib. Spectros., 2002, 30(2), p 169–173. https://doi.org/10.1016/S0924-2031(02)00022-X.

Ch.M. Parnell, B. Chhetri, T. Mitchell and F. Watanabe, Simultaneous Electrochemical Deposition of Cobalt Complex and Poly(pyrrole) Thin Films for Supercapacitor Electrodes, Sci. Rep., 2019, 9(1), p 5650.

Y. Zhang, G. Long, H. Tan, Z. Wang, Z. Zhang, W. Gao, R.S. Rawat and H. Jin Fan, Enhancing Bifunctionality of CoN Nanowires by Mn Doping for Long-Lasting Zn-Air Batteries, Sci. China-Chem., 2020, 63(7), p 890.

S.-K. Tien and J.-G. Duh, Effect of Heat Treatment on Mechanical Properties and Microstructure of CoN/AlN Multilayer Coatings, Thin Solid Films, 2006, 494, p 173–178.

J.C. Caicedo, C. Amaya, L. Yate, M.E. Gómez, G. Zambrano, J. Alvarado-Rivera, J. Muñoz-Saldaña and P. Prieto, TiCN/TiNbCN Multilayer Coatings with Enhanced Mechanical Properties, Appl. Surf. Sci., 2010, 256, p 5898–5904.

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24(8), p 981–988.

P. Nledengvist and S. Hogmark, Experiences from Scratch Testing od Tribological PVD Coatings, Tribol. Int., 1997, 30, p 507–516.

J.-W. Lee, S.-K. Tien, Y.-C. Kuo and C.-M. Chen, The Mechanical Properties Evaluation of the CrN Coatings Deposited by the Pulsed DC Reactive Magnetron Sputtering, Surf. Coat. Technol., 2006, 200, p 3330.

A. Leyland and A. Matthews, On the Significance of the H/E Ratio in Wear Control: A Nanocomposite Coating Approach to Optimised Tribological Behaviour, Wear, 2000, 1, p 246.

C. Escobar, M. Villarreal, J.C. Caicedo, J. Esteve and P. Prieto, Mechanical and Tribological Behavior of VN And HfN Films Deposited Via Reactive Magnetron Sputtering, Surface Rev. Lett., 2013, 20(3 & 4), p 1350040.

J.C. Caicedo, L. Yate, G. Cabrera, W. Aperador, G. Zambrano and P. Prieto, Effect of Negative Bias Voltage on Mechanical and Electrochemical Nature in Ti-W-N Coatings, J. Mater. Sci., 2011, 46, p 1244–1252.

Acknowledgments

This research was supported by Universidad Militar Nueva Granada, Bogotá, Colombia; CIC biomaGUNE, San Sebastian, Spain; Centro de Desarrollo Tecnológico y Asistencia Técnica a la Industria del Servicio Nacional de Aprendizaje (CDT-ASTIN-SENA), Cali, Colombia; Universidad Autónoma de Occidente, Cali, Colombia.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Caicedo, J.C., Aperador, W. & Riascos, H. Mechanical and Tribological Response of [CoN/AlN]n Multilayers Obtained from Laser Ablation. J. of Materi Eng and Perform 31, 4354–4368 (2022). https://doi.org/10.1007/s11665-022-06593-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06593-y