Abstract

Compact components are prone to failure at brazed joints. A comprehensive understanding of the effect of brazing temperature on the metallurgical reactions and microstructure evolution of 316L/BNi-2 brazed joints will provide support for optimization of the brazing process and improving joints strength. In this paper, the brazing process was carried out at 966°C 991°C, 1033°C, 1065°C, 1100°C, 1137°C and 1170°C in a vaccum furnace. The morphology and crystal structure of different zones of the brazed joints including athermal solidification zone (ASZ), isothermal solidification zone, and diffusion-affected zone (DAZ) were investigated. Results show that the DAZ begins to form, and the Ni3B, Ni3Si, CrB, and γ-Ni in the ASZ gradually coarsen below 1033°C. When the temperature reaches 1065°C, the filler alloy completely liquidizes. The boron in the filler alloy diffuses into the base metal, resulting in isothermal solidification. The residual liquid phase generates binary and ternary eutectic reactions. According to TEM patterns analysis in the DAZ, borides, and carbon-boride are mainly distributed on grain boundaries and within grains, respectively. In addition, M5B3 boride in the DAZ gradually transforms into M2B boride due to its better thermodynamic stability. Above 1170°C, the borides in the DAZ partly dissolve, and meanwhile, the matrix transforms from martensite to austenite, forming the alternating distribution of austenite and boride. During the heating process, with increasing brazing temperature, the hardness and elastic modulus of brazed joint microregions gradually decrease.

Similar content being viewed by others

References

A. Amirkhani, B. Beidokhti, K. Shirvani and M. Rahimipour, Two-Step Heating Transient Liquid Phase Bonding of Inconel 738LC, J. Mater. Process. Technol., 2019, 266, p 1–9.

H. Asahi, Effects of Mo Addition and Austenitizing Temperature on Hardenability of Low Alloy B-Added Steels, ISIJ Int., 2002, 42(10), p 1150–1155.

I. Baker, J. Yuan and E.M. Schulson, Formation of L1 2-Structured Ni 3 Si, Metall. Trans. A, 1993, 24(2), p 283–292.

B. Binesh and A.J. Gharehbagh, Transient Liquid Phase Bonding of IN738LC/MBF-15/IN738LC: Solidification Behavior and Mechanical Properties, J. Mater. Sci. Technol., 2016, 32(11), p 1137–1151.

J. Cao, Y. Wang, X. Song, C. Li and J. Feng, Effects of Post-Weld Heat Treatment on Microstructure and Mechanical Properties of TLP Bonded Inconel718 Superalloy, Mater. Sci. Eng., A, 2014, 590, p 1–6.

A.T. Dinsdale, SGTE data for pure elements. calphad, 1991, 15(4), p 317–425.

P.-Y. Duan, D.-X. Wang, G.-Y. Zhou and S.-T. Tu, Experimental Study on Peeling Performance of T-type Brazing Joints, Int. J. Press. Vessels Pip., 2019, 172, p 70–78.

G. Elmanov, E. Ivanitskaya, O. Sevryukov, V. Skrytnyi and A. Suchkov, Structural Phase Transformations and Changes in the Surface Topology upon Crystallization of Amorphous Alloys Based on Nickel, Inorg. Mater. Appl. Res., 2014, 5(3), p 237–244.

X. Hu, H. Niu, X. Ma, A. Oganov, C. Fisher, N. Sheng, J. Liu, T. Jin, X. Sun and J. Liu, Atomic-Scale Observation and Analysis of Chemical Ordering in M3B2 and M5B3 Borides, Acta Mater., 2018, 149, p 274–284.

O. Idowu, O. Ojo and M. Chaturvedi, Microstructural Study of Transient Liquid Phase Bonded Cast Inconel 738LC Superalloy, Metall. and Mater. Trans. A., 2006, 37(9), p 2787–2796.

W. Jiang, J. Gong and S. Tu, A study of the Effect of Filler Metal Thickness on Tensile Strength for a Stainless Steel Plate-Fin Structure by Experiment and Finite Element Method, Mater. Des., 2010, 31(5), p 2387–2396.

P. Kontis, H.M. Yusof, S. Pedrazzini, M. Danaie, K. Moore, P. Bagot, M. Moody, C. Grovenor and R. Reed, On the Effect of Boron on Grain Boundary Character in a New Polycrystalline Superalloy, Acta Mater., 2016, 103, p 688–699.

M. Kuntz, S. Corbin and Y. Zhou, Quantifying Metallurgical Interactions in solid/liquid Diffusion Couples Using Differential Scanning Calorimetry, Acta Mater., 2005, 53(10), p 3071–3082.

P. Maitrepierre, D. Thivellier and R. Tricot, Influence of Boron on the Decomposition of Austenite in Low Carbon Alloyed Steels, Metall. Trans. A, 1975, 6(2), p 287.

G. McMahon, S. Burgess, M. Takakura, H. Takahashi and M. Burke, Low Voltage X-ray Mapping: The Complementary Methods of the Oxford Instruments X-Max Extreme Windowless EDS Detector and the JEOL Soft X-Ray Emission Spectroscopy (SXES), Microsc. Microanal., 2016, 22(S3), p 440–441.

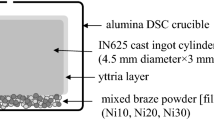

D. Murray and S. Corbin, Determining the Kinetics of Transient Liquid Phase Bonding (TLPB) of Inconel 625/BNi-2 Couples Using Differential Scanning Calorimetry, J. Mater. Process. Technol., 2017, 248, p 92–102.

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7(6), p 1564–1583.

D.Y. Park, S.K. Lee and Y.J. Oh, Taguchi Analysis of Relation Between Tensile Strength and Interfacial Phases Quantified via Image Processing, Metall. and Mater. Trans. A., 2018, 49(10), p 4684–4699.

M. Pouranvari, A. Ekrami and A. Kokabi, Solidification and Solid State Phenomena During TLP Bonding of IN718 Superalloy using Ni–Si–B Ternary Filler Alloy, J. Alloy. Compd., 2013, 563, p 143–149.

S. Raju, N.A. Kumar, B. Jeyaganesh, E. Mohandas and U.K. Mudali, Characterization of Crystallization Kinetics of a Ni-(Cr, Fe, Si, B, C, P) Based Amorphous Brazing Alloy by Non-Isothermal Differential Scanning Calorimetry, J. Alloy. Compd., 2007, 440(1–2), p 173–177.

J. Ruiz-Vargas, N. Siredey-Schwaller, P. Bocher and A. Hazotte, First Melting Stages During Isothermal Brazing, of Ni/BNi-2 Couples, J. Mater. Process. Technol., 2013, 213(12), p 2074–2080.

J. Ruiz-Vargas, N. Siredey-Schwaller, N. Gey, P. Bocher and A. Hazotte, Microstructure Development During Isothermal Brazing of Ni/BNi-2 Couples, J. Mater. Process. Technol., 2013, 213(1), p 20–29.

N. Sheng, X. Hu, J. Liu, T. Jin, X. Sun and Z. Hu, M 3 B 2 and M 5 B 3 Formation in Diffusion-Affected Zone During Transient Liquid Phase Bonding Single-Crystal Superalloys, Metall. and Mater. Trans. A., 2015, 46(4), p 1670–1677.

C.J. Smithells, Metals Reference Book, Elsevier, 2013.

T. Sourmail, T. Okuda and J. Taylor, Formation of Chromium Borides in Quenched Modified 310 Austenitic Stainless Steel, Scripta Mater., 2004, 50(10), p 1271–1276.

J. Takahashi, K. Ishikawa, K. Kawakami, M. Fujioka and N. Kubota, Atomic-Scale Study on Segregation Behavior at Austenite Grain Boundaries in Boron-and Molybdenum-Added Steels, Acta Mater., 2017, 133, p 41–54.

M. Tojo, T. Tokunaga, H. Ohtani and M. Hasebe, Thermodynamic Analysis of Phase Equilibria in the Cr–Mo–B Ternary System, Calphad, 2010, 34(3), p 263–270.

T. Tokunaga, K. Nishio and M. Hasebe, Thermodynamic Study of Phase Equilibria in the Ni-Si-B System, Journal of phase equilibria, 2001, 22(3), p 291.

S. Wang, Y. Sun, C. Cui, X. Sun, Y. Zhou, Y. Ma and H. An, Effect of Post-Bond Heat Treatment on the Microstructure and High Temperature Mechanical Property of a TLP Bonded γ′-Strengthened Co-based Single Crystal Superalloy, J. Mater. Sci. Technol., 2021, 80, p 244–258.

Wang Z-J, Li Y-W, Wang G-D, Liu H-T (2020) Effects of Boron Content on the Microstructure and Mechanical Properties of Twin-Roll Strip Casting Borated Steel Sheets. Materials Science and Engineering: A 793:139847

N. Wikstrom, O. Ojo and M. Chaturvedi, Influence of Process Parameters on Microstructure of Transient Liquid Phase Bonded Inconel 738LC Superalloy with Amdry DF-3 Interlayer, Mater. Sci. Eng., A, 2006, 417(1–2), p 299–306.

Xiao C, Jiang W, Yu Y, Song M, Tu S-T, Gong J (2020) Influence of Borides Dissolution During the Homogenization Treatment on the Mechanical Properties and Fracture Behavior of Austenitic Stainless Steel Brazed Joints. Mater. Sci. Eng. A: 139200

K. Yamada, H. Ohtani and M. Hasebe, Thermodynamic Analysis of the Fe-Cr-B Ternary System, High Temp. Mater. Processes (London), 2008, 27(4), p 269–284.

G. Yan, A. Bhowmik, B. Nagarajan, X. Song, S.C. Tan and M.J. Tan, Bonding Temperature Effects on the Wide Gap Transient Liquid Phase Bonding of INCONEL 718 Using BNi-2 Paste Filler Metal, Appl. Surf. Sci., 2019, 484, p 1223–1233.

S. Yoshida, K. Ushioda and J. Ågren, Kinetic Model of the γ to α Phase Transformation at Grain Boundaries in Boron-bearing Low-alloy Steel, ISIJ Int., 2014, 54(3), p 685–692.

L. Zhang, Q. Chang, Z. Sun, Q. Xue and J. Feng, Effects of Boron and Silicon on Microstructural Evolution and Mechanical Properties of Transient Liquid Phase Bonded GH3039/IC10 joints, J. Manuf. Process., 2019, 38, p 167–173.

B. Zhang, G. Sheng, Y. Jiao, Z. Gao, X. Gong, H. Fan and J. Zhong, Precipitation and Evolution of Boride in Diffusion Affected Zone of TLP Joint of Mar-M247 Superalloy, J. Alloy. Compd., 2017, 695, p 3202–3210.

W. Zhu, H. Jiang, H. Zhang, S. Sun and Y. Liu, Microstructure and Strength of High Nitrogen Steel Joints Brazed with Ni-Cr-B-Si Filler, Mater. Sci. Technol., 2018, 34(8), p 926–933.

Acknowledgments

The work was supported by the National Natural Science Foundation of China (Grant No 51675181).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, HY., Duan, Py., Liao, Pp. et al. Effect of Temperature on Metallurgical Reactions and Microstructure Evolution of 316L/BNi-2 Brazed Joints. J. of Materi Eng and Perform 31, 1631–1641 (2022). https://doi.org/10.1007/s11665-021-06296-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06296-w