Abstract

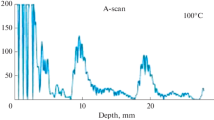

A material when exposed to high temperature under a constant load for a prolonged period, it experiences deformation due to Creep. The strength of precipitation hardening materials reduces when exposed to high temperature under load due to the coarsening of precipitates and their incoherency with the matrix. Growth of precipitates beyond a critical size introduces nonlinearity in the propagation of elastic waves through a material. This nonlinearity in the elastic waves can be measured by a parameter known as nonlinear ultrasonic (NLU) parameter which is proportional to the ratio of the amplitude of 2nd harmonic to the square of the amplitude of the fundamental frequency of the sinusoidal wave propagated through the material. This paper addresses the effect of generation and growth of precipitates and their sizes on the changes in NLU parameter in P92 steel, a prime candidate material for power plant, exposed at temperature 650 °C under a load of 120 MPa for a duration till the material ruptures due to creep. Two different mode of experiments under the same condition; multiple samples with single interruption (MSSI) and single sample with multiple interruptions (SSMI), were designed to establish NLU technique to assess the critical stage of the said material. It was observed that in both the test modes when the changes in the NLU parameter were plotted as a function of strain, the peak value of the NLU parameter corresponds to the onset of deterioration in the mechanical strength of the material. The results were verified through microstructural characterization and mechanical test.

Similar content being viewed by others

References

Y. Wang, K.H. Mayer, A. Scholz, C. Berger, H. Chilukuru, K. Durst and W. Blum, Development of New 11% Cr Heat Resistant Ferritic Steels with Enhanced Creep Resistance for Steam Power Plants with Operating Steam Temperatures up to 650 C, Mater. Sci. Eng. A, 2009, 510, p 180–184.

V. Skorobogatykh, I. Schenkova, V. Dudko, A. Belyakov, and R. Kaibyshev, Microstructure Evolution in a 9% Cr Heat Resistant Steel During Creep Tests, in Materials Science Forum, vol 638 (Trans Tech Publications, 2010), pp. 2315–2320

F. Abe, Long-Term Stabilization of Creep-Resistant Ferritic Steels for Highly Efficient Ultra-Supercritical Power Plants, in Advances in Science and Technology, vol 72 (Trans Tech Publications, 2010), pp. 12–21

K.H. Mayer, A. Scholz and Y. Wang, Investigations of Ferritic/Martensitic Super Heat Resistant 11–12% Cr Steels for 650 °C Power Plants, Mater. Wiss. Werkst., 2006, 37(10), p 806–811.

Y. Hasegawa, M. Ohgami and T. Murahi, Grain Boundary Strengthening Mechanism of Tungsten Containing 9 to 12% Chromium Ferritic Heat Resistant Steels at 650 deg C, J. Soc. Mater. Sci. Jpn., 2003, 52(7), p 843–850.

D. Rojas, J. Garcia, O. Prat, G. Sauthoff and A.R. Kaysser-Pyzalla, 9% Cr Heat Resistant Steels: Alloy Design, Microstructure Evolution and Creep Response at 650 C, Mater. Sci. Eng. A, 2011, 528(15), p 5164–5176.

K. Miyahara, J.H. Hwang and Y. Shimoide, Aging Phenomena Before the Precipitation of the Bulky Laves Phase in Fe-10% Cr Ferritic Alloys, Scr. Metall. Mater., 1995, 32(12), p 1917–1921.

J. Hald, Metallurgy and Creep Properties of new 9–12% Cr Steels, Steel Res. Int., 1996, 67(9), p 369–374.

A. Kostka, K.G. Tak, R.J. Hellmig, Y. Estrin and G. Eggeler, On the Contribution of Carbides and Micrograin Boundaries to the creep Strength of Tempered Martensite Ferritic Steels, Acta Mater., 2007, 55(2), p 539–550.

B. Raj, B.K. Choudhary and R.S. Raman, Mechanical Properties and Non-destructive Evaluation of Chromium–Molybdenum Ferritic Steels for Steam Generator Application, Int. J. Press. Vessels Pip., 2004, 81(6), p 521–534.

Z.J. Chen, M.R. Govindaraju, D.C. Jiles, S.B. Biner and M.J. Sablik, Assessment of Creep Damage of Ferromagnetic Material Using Magnetic Inspection, IEEE Trans. Magn., 1994, 30(6), p 4596–4598.

H. Willems, T. Jayakumar, T. Koble, and W. Theiner, in Proceedings of the 2nd annual report on project D4, Cost 501/II WP 5C, European Committee on Special Testing, IzfP Saarbrucken (1990)

H. Carreon, Detection of Creep Damage in a Nickel-Based Superalloy Turbine Bucket Using Eddy Current Imaging, Nondest. Test. Eval., 2009, 24(1–2), p 233–241.

A. Saxena, Electrical Potential Technique for Monitoring Subcritical Crack Growth at Elevated Temperatures, Eng. Fract. Mech., 1980, 13(4), p 741–750.

F. Masuyama, Creep Degradation in Welds of Mod. 9Cr-1Mo Steel, Int. J. Press. Vessels Pip., 2006, 83(11–12), p 819–825.

S. Kirihara, M. Shiga, M. Sukekawa, T. Yoshioka and C. Asano, Fundamental Study on Non-Destructive Detection of Creep Damage for Low Alloy Steel, J. Soc. Mater. Sci. Jpn., 1984, 33(371), p 1097–1102.

B.J. Cane, Remaining Creep Life Estimation by Strain Assessment on Plant, Int. J. Press. Vessels Pip., 1982, 10(1), p 11–30.

A. Pyzalla, B. Camin, T. Buslaps, M. Di Michiel, H. Kaminski, A. Kottar, A. Pernack and W. Reimers, Simultaneous Tomography and Diffraction Analysis of Creep Damage, Science, 2005, 308(5718), p 92–95.

X. Wang, X. Wang, X.G. Niu, D.M. Xiao and X.L. Hu, Application of Nonlinear Ultrasonic Technique to Characterize the Creep Damage in ASME T92 Steel Welded Joints, NDT and E Int., 2018, 98, p 8–16.

T. Ohtani, H. Ogi and M. Hirao, Noncontact Evaluation of Surface-Wave Nonlinearity for Creep Damage in Cr–Mo–V Steel, Jpn. J. Appl. Phys., 2009, 48(7S), p 07GD02.

S. Baby, B.N. Kowmudi, C.M. Om Prakash, D.V.V. Satyanarayana, K. Balasubramaniam and V. Kumar, Creep damage assessment in titanium alloy using a nonlinear ultrasonic technique, Scr. Mater., 2008, 59(8), p 818–821.

J.S. Valluri, K. Balasubramaniam and R.V. Prakash, Creep Damage Characterization Using Non-linear Ultrasonic Techniques, Acta Mater., 2010, 58(6), p 2079–2090.

C. Kim, Creep Damage Characterization of Ni-Based Super Alloy by Acoustic Nonlinearity, Prog. Nat. Sci. Mater. Int., 2012, 22(4), p 303–310.

J. Park, M. Kim, B. Chi and C. Jang, Correlation of Metallurgical Analysis & Higher Harmonic Ultrasound Response for Long Term Isothermally Aged and Crept FM Steel for USC TPP Turbine Rotors, NDT E Int., 2013, 54, p 159–165.

J. Kang, J. Qu, A. Saxena, and l. Jacobs, On the Detection of Creep Damage in a Directionally Solidified Nickel Base Superalloy Using Nonlinear Ultrasound, in AIP Conference Proceedings, vol 700, no 1 (2004), pp. 1248–1255

Y. Xiang, M. Deng and F.Z. Xuan, Creep Damage Characterization Using Nonlinear Ultrasonic Guided Wave Method: A Mesoscale Model, J. Appl. Phys., 2014, 115(4), p 044914.

K.Y. Jhang, Nonlinear Ultrasonic Techniques for Non-destructive Assessment of Micro Damage in Material: A Review, Int. J. Precis. Eng. Manuf., 2009, 10(1), p 123–135.

A.N. Norris, in Nonlinear Acoustics, ed. M. Hamilton, D. Blackstock (Academic Press, San Diego, CA, 1998), pp. 263–264

D.C. Wallace, Thermoelasticity of Stressed Materials and Comparison of Various Elastic Constants, Phys. Rev., 1967, 162(3), p 776.

J.H. Cantrell, Crystalline Structure and Symmetry Dependence of Acoustic Nonlinearity Parameters, J. Appl. Phys., 1994, 76(6), p 3372–3380.

J. Melngailis, A.A. Maradudin and A. Seeger, Diffraction of Light by Ultrasound in Anharmonic Crystals, Phys. Rev., 1963, 131(5), p 1972.

M.D. Mathew, K.L. Murty, K.B.S. Rao and S.L. Mannan, Ball Indentation Studies on the Effect of Aging on Mechanical Behaviour of Alloy 625, Mater. Sci. Eng. A, 1999, 264(1), p 159–166.

G. Das, S. Ghosh and S.K. Sahay, Use of Ball Indentation Technique to Determine the Change of Tensile Properties of SS316L Steel Due to Cold Rolling, Mater. Lett., 2005, 59(18), p 2246–2251.

V. Karthik, P. Visweswaran, A. Bhushan, D.N. Pawaskar, K.V. Kasiviswanathan, T. Jayakumar and B. Raj, Finite Element Analysis of Spherical Indentation to Study Pile-Up/Sink-In Phenomena in Steels and Experimental Validation, Int. J. Mech. Sci., 2012, 54(1), p 74–83.

A. Metya, M. Ghosh, N. Parida and S.P. Sagar, Higher Harmonic Analysis of Ultrasonic Signal for Ageing Behaviour Study of C-250 Grade Maraging Steel, NDT E Int., 2008, 41(6), p 484–489.

Acknowledgments

Authors are grateful to the Director, CSIR-National Metallurgical Laboratory, Jamshedpur for his kind permission to publish this work. The first author also acknowledges the financial support from the Council of Scientific and Industrial Research (CSIR), India.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sahu, M., Sagar, S.P. A Non-invasive Technique to Estimate the Onset of Creep Strength Deterioration. J. of Materi Eng and Perform 31, 1642–1653 (2022). https://doi.org/10.1007/s11665-021-06272-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06272-4