Abstract

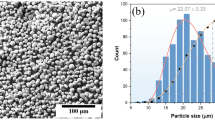

In order to study the thermal deformation behavior of a low-carbon steel, the samples were subjected to a single-pass thermal compression test on the Gleeble-1500 thermal simulator. The compression temperature was 900-1200 °C, and the strain rate was 0.01-10 s−1. Based on the experimental results, a strain-compensated Arrhenius constitutive model and a physical constitutive model based on dynamic recrystallization were established. The correlation coefficient and average absolute relative error were used to appraisal the accuracy of models. These models were compared and both models can be used to predict the hot deformation behavior of the test steel. Furthermore, processing maps were established at the strains of 0.2, 0.4, 0.6, 0.8 and 1.0 to study the optimal processing conditions for the tested steel. The processing maps imply that two plastic instability zones formed at the areas of low temperature with high strain rate and high temperature with high strain rate, where the hot working process should be avoided. The optimal processing conditions for the tested steel are 1100-1175 °C and 1.35×10−1–6×10−1 s−1.

Similar content being viewed by others

References

C.M. Sellars and W.J. Mctegart, On the Mechanism of Hot Deformation, Acta Metall., 1966, 14(9), p 1136–1138.

A. Bergstrom and B. Aronsson, The Application of a Dislocation Model to the Strain and Temperature Dependence of the Strain Hardening Exponent n, in the Ludwik-Hollomon Relation Between Stress and Strain in Mild Steels, Metall. Mater. Trans. B., 1972, 3(7), p 1951–1957.

A. Laasraoui and J.J. Jonas, Prediction of Steel Flow Stresses at High Temperatures and Strain Rates, Metall. Mater. Trans. A., 1991, 22(7), p 1545–1558.

R.B. Li, Y.Q. Chen, C.X. Jiang, R.L. Zhang, Y.P. Fu, T. Huang and T.T. Chen, Hot Deformation Behavior and Processing Maps of a 9Ni590B Steel International, J. Mater. Eng. Perform., 2020, 29, p 3858–3867.

R.X. Zhai, W. Wang, R. Ma, S.J. Zhang, S.B. Ma, L.P. Li, S.Y. Gong and H.J. Zhang, Hot Deformation Behavior and Processing Map of As-Cast 40CrNiMo Alloy Steel, J. Mater. Eng. Perform., 2020, 9(2), p 1929–1940.

W.L. Cheng, Y. Bai, S.C. Ma, L.F. Wang, H.X. Wang and H. Yu, Hot Deformation Behavior and Workability Characteristic of a Fine-Grained Mg-8Sn-2Zn-2Al Alloy with Processing Map, J. Mater. Sci. Technol., 2019, 35, p 1198–1209.

J.G. He, J.B. Wen, X.D. Zhou and Y.Y. Liu, Hot Deformation Behavior and Processing Map of Cast 5052 Aluminum Alloy, Procedia Manuf., 2019, 37, p 2–7.

J.B. Zhang, C.J. Wu, Y.Y. Peng, X.C. Xia, J.G. Li, J. Ding, C. Liu, X.G. Chen, J. Dong and Y.C. Liu, Hot Compression Deformation Behavior and Processing Maps of ATI 718Plus Superalloy, J. Alloys Compd., 2020, 835, p 155195.

W.Z. Bao, L.K. Bao, D. Liu, D.Y. Qu, Z.Z. Kong, M.J. Peng and Y.H. Duan, Constitutive Equations, Processing Maps, and Microstructures of Pb-Mg-Al-B-0.4Y Alloy Under Hot Compression, J. Mater. Eng. Perform., 2020, 29, p 607–619.

X.S. Xia, K. Zhang, M.L. Ma and T. Li, Constitutive Modeling of flow Behavior and Processing Maps of Mg-8.1Gd-4.5Y-0.3Zr alloy, J. Magnes. Alloys, 2020, 8(3), p 917–928.

H.T. Zhao, J.J. Qi, R. Su, H.Q. Zhang, H.W. Chen, L.J. Bai and C.G. Wang, Hot deformation Behaviour of 40CrNi Steel and Evaluation of Different Processing Map Construction Methods, J. Mater. Res. Technol., 2020, 9(3), p 2856–2869.

B. Ke, L.Y. Ye, J.G. Tang, Y. Zhang, S.D. Liu, H.Q. Lin, Y. Dong and X.D. Liu, Hot Deformation Behavior and 3D Processing Maps of AA7020aluminum Alloy, J. Alloys Compd., 2020, 845, p 156113.

Y.H. Sun, R.C. Wang, J. Ren, C.Q. Peng and Y. Feng, Hot Deformation Behavior of Mg-8Li-3Al-2Zn-02Zr Alloy Based on Constitutive Analysis, Dynamic Recrystallization Kinetics, and Processing Map, Mech. Mater., 2019, 131, p 158–168.

C. Zhang, L.W. Zhang, W.F. Shen, C.R. Liu, Y.N. Xia and R.Q. Li, Study on Constitutive Modeling and Processing Maps for Hot Deformation of Medium Carbon Cr-Ni-Mo Alloyed Steel, Mater. Des., 2016, 90, p 804–814.

H.C. Ji, H.L. Duan, Y.G. Li, W.D. Li, X.M. Huang, W.C. Pei and Y.H. Lu, Optimization the Working Parameters of as-Forged 42CrMo Steel by Constitutive Equation-Dynamic Recrystallization Equation and Processing Maps, J. Mater. Res. Technol., 2020, 9, p 7210–7224.

W.F. Shen, L.W. Zhang, C. Zhang, Y.F. Xu and X.H. Shi, Constitutive Analysis of Dynamic Recrystallization and Flow Behavior of a Medium Carbon Nb-V Microalloyed Steel, J. Mater. Eng. Perform., 2016, 25(5), p 2065–2073.

A. He, G.L. Xie, X.Y. Yang, X.T. Wang and H.L. Zhang, A Physically-Based Constitutive Model for a Nitrogen Alloyed Ultralow Carbon Stainless Steel, Comput. Mater. Sci., 2015, 98, p 64–69.

G.L. Ji, Q. Li and L. Li, A Physical-Based Constitutive Relation to Predict Flow Stress for Cu-0.4Mg Alloy During Hot Working, Mater. Sci. Eng. A., 2014, 615, p 247–254.

Y. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark and D.R. Barker, Modeling of Dynamic Material Behavior in Hot Deformation-Forging of Ti-6242, Metall. Trans. A., 1984, 15(10), p 1883–1892.

A. Lukaszek-Solek, J. Krawczyk, T. Sleboda and J. Grelowski, Optimization of the Hot Forging Parameters for 4340 Steel by Processing Maps, J. Mater. Res. Technol., 2019, 8(3), p 3281–3290.

Q.Y. Liao, Y.C. Jiang, Q.C. Le, X.R. Chen, C.L. Cheng, K. Hu and D.D. Li, Hot Deformation Behavior and Processing Map Development of AZ110 Alloy with and Without Addition of La-Rich Mish Metal, J. Mater. Sci. Technol., 2020, 61, p 1–15.

M. Patnamsetty, M.C. Somani, S. Ghosh, S. Ahmed and P. Peura, Processing Map for Controlling Microstructure and Unraveling Various Deformation Mechanisms During Hot Working of CoCrFeMnNi High Entropy Alloy, Mater. Sci. Eng. A., 2020, 793, p 139840.

Q.B. Yang, L. Lei, X.G. Fan, Z.H. Jia, Z.Q. Zhang, W.G. Li and Q. Liu, Microstructure Evolution and Processing Map of Al-Cu-Li-Mg-Ag Alloy, Mater. Chem. Phys., 2020, 254, p 123256.

X.W. Yang and W. Li, Flow Behavior and Processing Maps of a Low-Carbon Steel During Hot Deformation, Metall. Mater. Trans. A., 2015, 46A, p 6052–6064.

S.K. Rajput, G.P. Chaudhari and S.K. Nath, Characterization of Hot Deformation Behavior of a Low Carbon Steel Using Processing Maps, Constitutive Equations and Zener-Hollomon Parameter, J. Mater. Process. Technol., 2016, 237, p 113–125.

L. Wang, L.Z. Gu and D.C. Hu, High-Temperature Deformation Behaviour and Microstructural Evolution of Low Carbon Steel Based on Processing Map, Ironmaking Steelmaking., 2019, 46(4), p 335–342.

W. Wei, C.L. Yuan, R.D. Wu, W. Jiao and D.C. Liang, Constitutive Modeling and Analysis on High-Temperature Flow Behavior of 25 Steel, J. Iron Steel Res. Int., 2021, 28, p 76–85.

H. Mirzadeh, J.M. Cabrera and A. Najafizadeh, Constitutive Relationships for Hot Deformation of Austenite, Acta Mater., 2011, 59(16), p 6441–6448.

Y.C. Lin, F.Q. Nong, X.M. Chen, D.D. Chen and M.S. Chen, Microstructural Evolution and Constitutive Models to Predict Hot Deformation Behaviors of a Nickel-Based Superalloy, Vacuum, 2017, 137, p 104–114.

S.W. Wu, X.G. Zhou, G.M. Cao, Z.Y. Liu and G.D. Wang, The Improvement on Constitutive Modeling of Nb-Ti Micro Alloyed Steel by Using Intelligent Algorithms, Mater. Des., 2017, 116, p 676–685.

C. Zener and J.H. Hollomon, Effect of Strain Rate Upon Plastic Flow of Steel, J. Appl. Phys., 1944, 15(1), p 22–27.

P. Zhang, C. Yi, G. Chen, H.Y. Qin and C.J. Wang, Constitutive Model Based on Dynamic Recrystallization Behavior During Thermal Deformation of a Nickel-Based Superalloy, Metals., 2016, 6, p 161.

G.L. Ji, Q. Li, K.Y. Ding, L. Yang and L. Li, A Physically-Based Constitutive Model for High Temperature Deformation of Cu-0.36Cr-0.03Zr Alloy, J. Alloys Compd., 2015, 648, p 397–407.

A.M. Jorge Jr. and O. Balancin, Prediction of Steel Flow Stresses Under Hot Working Conditions, Mater. Res., 2005, 8(3), p 309–315.

J.J. Jonas, X. Quelennec, L. Jiang and E. Martin, The Avrami Kinetics of Dynamic Recrystallization, Acta Mater., 2009, 57, p 2748–2756.

Y.J. Li, Y. Zhang, Z.Y. Chen, Z.C. Ji, H.Y. Zhu, C.F. Sun, W.P. Dong, X. Li, Y. Sun and S. Yao, Hot Deformation Behavior and Dynamic Recrystallization of GH690 Nickel-Based Superalloy, J. Alloys Compd., 2020, 847, p 156507.

C.J. Wang, L.Q. Zhang, S.Z. Wei, X.Q. Li, X.C. Wu, Q.K. Li and K.M. Pan, Establishment of Processing Map, Microstructure and High-Temperature Tensile Properties of W-0.25 wt% Al2O3 Alloys, J. Alloys Compd., 2020, 831, p 154751.

J.J. Liu, K.L. Wang, S.Q. Lu, X.Y. Gao, X. Li and F. Zhou, Hot Deformation Behavior and Processing Map of Zr-4 Alloy, J. Nucl. Mater., 2020, 531, p 1511993.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51604058), Joint Research Fund of Natural Science Foundation of Liaoning—the State Key Laboratory of Rolling and Automation, Northeastern University (2019KF0506) the Ministry of Science and Technology of China (2019YFA0705304), and the Fundamental Research Funds for the Central Universities of China (DUT19JC26).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, C., Zhang, L., Li, F. et al. Constitutive Modeling of Flow Behavior and Processing Maps of a Low-Carbon Steel. J. of Materi Eng and Perform 31, 895–906 (2022). https://doi.org/10.1007/s11665-021-06233-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06233-x