Abstract

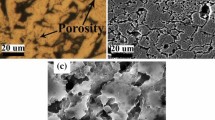

The low nickel austenitic stainless steel (LNiASS) is more economical than the conventional 300-series austenitic stainless steels as 60% (approx.) of the Ni is replaced by manganese; it exhibits similar mechanical properties but inferior corrosion resistance. In this work, low nickel austenitic stainless steel samples were coated with Ni-based metallic powders using a thermal spray coating technique. The microstructures, phase composition and properties of coatings were examined using SEM, EDS, XRD and Vickers’s microhardness. The corrosion behavior was investigated by potentiodynamic polarization test in 0.5 M H2SO4 solution and 3.5 wt.% NaCl solution both for the uncoated and coated specimen. In both test solutions, the coatings that contained molybdenum and more chromium showed better corrosion resistance. The coated low nickel austenitic stainless steel can, therefore, be a cost-effective alternative to replace the widely used austenitic stainless steel in commercial as well as industrial applications.

Similar content being viewed by others

References

R.V. Taiwade, R. Shukla, H. Vashishtha, A.V. Ingle and R.K. Dayal, Effect of Grain Size on Degree of Sensitization of Chrome-Manganese Stainless Steel, ISIJ Int., 2013, 53, p 2206–2212.

H. Vashishtha, R.V. Taiwade, R.K. Khatirkar, A.V. Ingle and R.K. Dayal, Welding Behaviour of Low Nickel Chrome-Manganese Stainless Steel, ISIJ Int., 2014, 54, p 1361–1367.

D. Gopi, P. Karthikeyan, L. Kavitha and M. Surendirana, Development of Poly(3,4-Ethylenedioxythiophene-Co-Indole-5-Carboxylic Acid) Co-Polymer Coatings on Passivated Low-Nickelstainless Steel for Enhanced Corrosion Resistance In The Sulphuricacid Medium, Appl. Surf. Sci., 2015, 357, p 122–130.

R. Dalipi, L. Borgese, A. Casaroli, M. Boniardi, U. Fittschen, K. Tsuji and L.E. Depero, Study of Metal Release from Stainless Steels in Simulated Food Contact by Means Of Total Reflection X-ray Fluorescence, J. Food Eng., 2016, 173, p 85–91.

H. Vashishtha, R.V. Taiwade, S. Sharma and A.P. Patil, Effect of Welding Processes on Microstructural and Mechanical Properties of Dissimilar Weldments Between Conventional Austenitic and High Nitrogen Austenitic Stainless Steels, J. Manuf. Process., 2017, 25, p 49–59.

C. Donik, I. Paulin and M. Jenko, Influence of MnS Inclusions on the Corrosion of Austenitic Stainless Steels, Mater. Technol., 2010, 44, p 67–72.

N.N. Khobragade, M.I. Khan and A.P. Patil, Corrosion Behaviour of Chrome-Manganese Austenitic Stainless Steels and AISI 304 Stainless Steel in Chloride Environment, Trans. Indian Inst. Met., 2014, 67, p 263–273.

D. Gopi, K.M. Govindaraju, L. Kavitha and K. Basha, Synthesis, Characterization and Corrosion Protection Properties of Poly(N-vinyl Carbazole-co-glycidyl Methacrylate) Coatings on Low Nickel Stainless Steel, Prog. Org. Coat., 2011, 71, p 11–18.

F.S. Rogers, Thermal Spray for Commercial Shipbuilding, J. Therm. Spray Technol, 1997, 6, p 291–293.

V.R.S. Sá Brito, Corrosion Resistance and Characterization of Metallic Coatings Deposited by Thermal Spray on Carbon Steel, Mater. Des., 2012, 41, p 282–288.

B.A. Kushner and E.R. Novinski, Thermal Spray Coatings, ASM Handbook, 1992, 18, p 829–833.

K. Holmberg and A. Matthews, Coatings Tribology, Elsevier, London, 2009.

N. Vashishtha, S.G. Sapate, P. Bagde and A.B. Rathod, Effect of Heat Treatment on Friction and Abrasive Wear Behaviour of WC-12Co and Cr3C2-25NiCr Coatings, Tribol. Int., 2018, 118, p 381–399.

N. Vashishtha, S.G. Sapate and P. Bagde, Effect of Tribo-Oxidation on Friction and Wear Behaviour of HVOF Sprayed WC-10Co-4Cr Coating, Tribol. Lett., 2018, 66, p 56.

J. Rodriuez, A. Martin, R. Fernández and N.D.J.E. Fernández, An Experimental Study of the Wear Performance of NiCrBSi Thermal Spray Coatings, Wear, 2003, 255, p 950–955.

S. Amin and H. Panchal, A Review on Thermal Spray Coating Processes, Int. J. Curr. Trend Eng. Res., 2016, 2, p 556–563.

P. Fauchais, and A. Vardelle, (2012) Thermal Sprayed Coatings Used Against Corrosion and Corrosive Wear, Advanced Plasma Spray Applications

F. Gärtner, T. Stoltenhoff, T. Schmidt and H. Kreye, The Cold Spray Process and Its Potential for Industrial Applications, J. Therm. Spray Technol., 2006, 15, p 223–232.

S.P. Brühl, R. Charadia, S. Simison, D.G. Lamas and A. Cabo, Corrosion Behavior of Martensitic and Precipitation Hardening Stainless Steels Treated by Plasma Nitriding, Surf. Coat. Technol., 2010, 204, p 3280–3286.

C.T. Liu, J. Stringer, J.N. Mundy, L.L. Horton and P. Angelini, Ordered Intermetallic Alloys: an Assessment, Intermetallics, 1997, 5, p 579–596.

H.M. Wang, C.M. Wang and L.X. Cai, Wear and Corrosion Resistance of Laser Clad Ni2SiyNiSi Composite Coatings, Surf. Coat. Technol., 2003, 168, p 202–208.

Y. Wang, Q. Zhou and Q. Zhong, A Magnetic Properties and Corrosion Resistance of Fe-Si Alloy Coating Prepared on Mild Steel, Mater. Sci., 2014, 20, p 1392–1320.

J.D. Bolton, E.R. Petty and G.B. Allen, The Mechanical Properties of α-Phase Low-Carbon Fe-Mn Alloys, Metallugical transaction, 1971, 2, p 2915–2923.

Y. Fu, X. Wu, E.H. Han, W. Ke, K. Yang and Z. Jiang, Effects of Cold Work and Sensitization Treatment on the Corrosion Resistance of High Nitrogen Stainless Steel in Chloride Solutions, Electrochim. Acta., 2009, 54, p 1618–1629.

M.J. Carmezim, A.M. Simões, M.F. Montemor and M.D.C. Belo, Capacitance Behaviour of Passive Films on Ferritic and Austenitic Stainless Steel, Corros. Sci., 2005, 47, p 581–591.

Q.Y. Wanga, S.L. Bai, Y.F. Zhanga and Z.D. Liu, Improvement of Ni–Cr–Mo Coating Performance by Laser Cladding Combined Re-melting, Appl. Surf. Sci., 2014, 308, p 285–292.

A. Kocijan, C. Donik and M. Jenko, The Corrosion Behaviour of Duplex Stainless Steel in Chloride Solutions Studied by XPS, Mater. Technol., 2009, 43, p 195–199.

J.A. Platt, A. Guzman, A. Zuccari, D.W. Thornburg, B.F. Rhodes, Y. Ossida and B.K. Moore, The Corrosion Behavior of Austenitic and Duplex Stainless Steel in Artificial Body Fluids”, Am. J. Ortodontics and Dentofacial Orthopedics, 1997, 112, p 69–79.

M.H. Brown, Behavior of Austenitic Stainless Steels in Evaluation Tests for Detection of Susceptibility to Intergranular Corrosion, Corrosion, 1974, 30, p 1–12.

R. Gonz´alez, M. Cadenas, R. Fern´andez, J.L. Cortizo, E. Rodr´ıguez, , Wear Behaviour of Flame Sprayed NiCrBSi Coating Remelted by Flame or by Laser, Wear, 2007, 262, p 301–307.

Z. Bergant and J. Grum, Quality Improvement of Flame sprayed, Heat Treated, and RemeltedNiCrBSi Coatings, J. of Therm. Spray Technol., 2009, 18, p 380–391.

T.W. Clyne and S.C. Gill, Residual Stresses in Thermal Spray Coatings and Their Effect on Interfacial Adhesion: A Review of Recent Work, ASM Int., 1996, 5, p 401–418.

P. Zhang, R.L. Peng, X.H. Li and S. Johansson, Investigation of Element Effect on High-Temperature Oxidation of HVOF NiCoCrAlX Coatings, Coatings, 2018, 8, p 129–146.

V. Kuzucu, M. Aksoy and M.H. Korkut, The Effect of Strong Carbide-forming Elements such as Mo, Ti, V and Nb on the Microstructure of Ferritic Stainless Steel, J. Mater. Process. Technol., 1998, 82, p 165–171.

T. Sundararajan, S. Kuroda and F. Abe, Steam Oxidation Studies on 50Ni-50Cr HVOF Coatings on 9Cr-1Mo Steel: Change in Structure and Morphology Across the Coating/Substrate Interface, Mater. Trans., 2004, 45, p 1299–1305.

J. Zhanga, S. Li, C. Lu, C. Sun, S. Pu, Q. Xue, Y. Lin and M. Huang, Anti-Wear Titanium Carbide Coating on Low-Carbon Steel By Thermo-Reactive Diffusion, Surf. Coat. Tech., 2019, 346, p 256–272.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Marodkar, A.S., Taiwade , R.V. & Vashishtha, H. Corrosion Behavior of Ni-Based Metallic Coatings Deposited by Thermal Spray Method on Low Nickel Austenitic Stainless Steel. J. of Materi Eng and Perform 31, 64–74 (2022). https://doi.org/10.1007/s11665-021-06200-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06200-6