Abstract

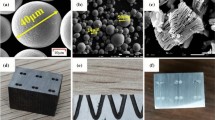

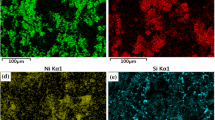

Improving the tribological properties and reducing the friction noise of Inconel 625 is of great significance for the extended application of Inconel 625 in mechanical parts and other fields. In this paper, composite anti-wear surfaces (CASs) with micro-texture filled by Sn-Ag-Cu (SAC) were prepared. The tribological and frictional noise properties of CASs and smooth surface (SS) with different texture spacing during dry sliding friction process were studied through a series of experiments, tests and analyses. The results show that CASs can improve tribological properties and noise suppression performance significantly. With the texture density of 25 % (CASs-1200), the friction coefficient is 0.464 under a load of 20 N, the wear rate is about 2.65×10−5 mm3/(N·m), and the friction noise is 88-89.5 dB. Due to the synergistic effect of surface microgrooves and solid lubricants, the excellent tribological performance of CASs was realized. Microgrooves make the lubricant mixture be easier precipitated onto the worn surface. An intact lubrication film with high shear fitness was formed on the worn surface, reducing the direct contact between the grinding ball and the substrate. Meanwhile, it reduces the radiated energy generated by the collision between the counterpart ball and matrix and the transition of counterpart ball on the uneven small platform, so as to achieve the effect of noise suppression. Especially, suppression effect of high-frequency noise in 2400-3000 Hz is close to 100 % in CASs-1200, inhibiting the high-frequency scream effectively.

Similar content being viewed by others

References

S.K. Rai, A. Kumar, V. Shankar, T. Jayakumar, K.B.S. Rao and B. Raj, Characterization of Microstructures in Inconel 625 using X-ray Diffraction Peak Broadening and Lattice Parameter Measurements, Scr. Mater., 2004, 51, p 59–63.

V. Shankar, K.B.S. Rao and S.L. Mannan, Microstructure and Mechanical Properties of Inconel 625 Superalloy, J. Nucl. Mater., 2001, 288, p 222–232.

G.P. Dinda, A.K. Dasgupta and J. Mazumder, Laser Aided Direct Metal Deposition of Inconel 625 Superalloy: Microstructural Evolution and Thermal Stability, Mater. Sci. Eng. A, 2009, 509, p 98–104.

M. Nakada, Trends in Engine Technology and Tribology, Tribol. Int., 1994, 27, p 3–8.

I. Etsion, State of the Art in Laser Surface Texturing, J. Tribol-T ASME, 2005, 127, p 248–253.

X.L. Wang, K. Adachi, K. Otsuka and K. Kato, optimization of the Surface Texture for Silicon Carbide Sliding in Water, Appl. Surf. Sci., 2006, 253, p 1282–1286.

A.S. Bychkov and V.N. Fedirko, analysis of the In-service Failures of Metal Structures of the Aircraft Equipment, Mater. Sci., 2016, 52, p 9–16.

J. Qu, P.J. Blau, T.R. Watkins, O.B. Cavin and N.S. Kulkarni, Friction and Wear of Titanium Alloys Sliding Against Metal, Polymer, and Ceramic Counterfaces, Wear, 2005, 258, p 1348–1356.

C. Muratore and A.A. Voevodin, Chameleon Coatings: Adaptive Surfaces to Reduce Friction and Wear in Extreme Environments, Annu. Rev. Mater. Res., 2009, 39, p 297–324.

X. Wang, S. Yuan and W. Huang, orientation Effects of Micro-grooves on Sliding Surfaces, Tribol. Int., 2011, 44, p 1047–1054.

L. Rapoport, A. Moshkovich, V. Perfilyev, I. Lapsker and I. Etsion, Friction and Wear of MoS2 Films on Laser Textured Steel Surfaces, Surf Coat Technol., 2008, 202, p 3332–3340.

D. He, S. Zheng, J. Pu, G. Zhang and L. Hu, Improving Tribological Properties of Titanium Alloys by Combining Laser Surface Texturing and Diamond-like Carbon Film, Tribol. Int., 2015, 82, p 20–27.

W.Z. Zhai, L.C. Bai, R.H. Zhou, X.L. Fan, G.Z. Kang, Y. Liu and K. Zhou, Recent Progress on Wear-Resistant Materials: Designs, Properties, and Applications, Adv. Sci., 2021, 8, p 2003739.

D.W. Wang, J.L. Mo, Z.Y. Zhu, H. Ouyang, M.H. Zhu and Z.R. Zhou, Debris Trapping and Space-varying Contact via Surface Texturing for Enhanced Noise Performance, Wear, 2018, 396–397, p 86–97.

D. Segu, J. Kim, S. Choi, Y.S. Jung and S.S. Kim, Application of Taguchi Techniques to Study Friction and Wear Properties of MoS2 Coatings Deposited on Laser Textured Surface, Surf. Coat. Tech., 2013, 232, p 504–514.

W. Zhai, X. Shi, J. Yao, Z. Xu and A. Mohanmed, Synergetic Lubricating Effect of WS2 and Ti3SiC2 on Tribological Properties of Ni3Al Matrix Composites at Elevated Temperatures, Tribol. Trans., 2015, 58, p 454–466.

S. Yan, Q. Ling, H. Rui and Z. Liu, A Novel Inward Gradient Self-Lubrication Layer with Soft Alloys and Its Lubricating Mechanism, Adv. Mater. Sci. Eng., 2016, 5, p 1–7.

C. Lin, M.S. Zou, C. Sima, S.X. Liu and L.W. Jiang, Friction-induced Vibration and Noise of Marine Stern Tube Bearings Considering Perturbations of the Stochastic Rough Surface, Tribol. Int., 2019, 131, p 661–671.

J.J. Sinou, A. Loyer, O. Chiello, G. Mogenier, X. Lorang, F. Cocheteux and S. Bellaj, A Global Strategy Based on Experiments and Simulations for Squeal Prediction on Industrial Railway Brakes, J. Sound Vib., 2013, 332, p 5068–5085.

J. Kang and K. Kim, Squeak Noise in Lead Screw Systems: Self-excited Vibration of Continuous Model, J. Sound Vib., 2010, 329, p 3587–3595.

J.L. Mo, Z.G. Wang, G.X. Chen, T.M. Shao, M.H. Zhu and Z.R. Zhou, The Effect of Groove-Textured Surface on Friction and Wear and Friction-Induced Vibration and Noise, Wear, 2013, 301, p 671–681.

M. Kchaou, A.R.M. Lazim, A.R.A. Bakar, J. Fajoui, R. Elleuch and F. Jacquemin, Effects of Steel Fibers and Surface Roughness on Squealing Behavior of Friction Materials, Trans. Indian Inst. Met., 2016, 69, p 1277–1287.

P. Koshy and J. Tovey, Performance of Electrical Discharge Textured Cutting Tools, CIRP Ann. Manuf. Technol., 2011, 60, p 153–156.

Y. Wan and D. Xiong, The Effect of Laser Surface Texturing on Frictional Performance of Face Seal, J. Mater. Process. Technol., 2008, 197, p 96–100.

T. Hu, Y. Zhang and L. Hu, Tribological Investigation of MoS2 Coatings Deposited on the Laser Textured Surface, Wear, 2012, 278–279, p 77–82.

B. Chen, Q. Bi, J. Yang, Y. Xia and J. Hao, Tribological Properties of Solid Lubricants (graphite, h-BN) for Cu-based P/M Friction Composites, Tribol. Int., 2008, 41, p 1145–1152.

X. Deng, X.L. Shi, X.Y. Liu and B. Xue, Study on the Thickness of Lubricating Film of M50-Ag Self-lubricating Composites, Lubr. Sci., 2019, 31, p 11–20.

H.B. Abdelounis, A.L. Bot, J. Perret-Liaudet and H. Zahouani, An Experimental Study on Roughness Noise of dry Rough Flat Surfaces, Wear, 2010, 268, p 335–345.

Acknowledgments

This work was supported by Guangdong Provincial Natural Science Foundation of China (2021A1515010624) and Fundamental Research Funds for the Central Universities (2019III138CG). Authors are also grateful to X.L. Nie, Y.M. Li, M.J. Yang, W.T. Zhu, S.L. Zhao and L.Q. Qin in Material Research and Test Center of WUT for their kind help with SEM, EPMA, FESEM and XRD.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, J., Wu, C., Shi, X. et al. Tribological Properties and Frictional Noise Behavior of Inconel 625 with Micro-texture Filled by Sn-Ag-Cu. J. of Materi Eng and Perform 31, 82–93 (2022). https://doi.org/10.1007/s11665-021-06157-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06157-6