Abstract

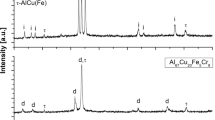

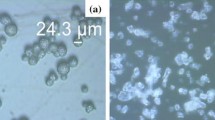

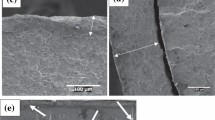

Nickel-aluminum bronze (NAB) alloys are widely used in hydraulic and pumping bodies due to their suitable mechanical properties and corrosion resistance. However, the tribological performance of these materials needs to be improved. In this study, the WC-10Co-4Cr, and Colmonoy-6 coatings were applied on a NAB alloy using high-velocity oxy-fuel (HVOF) spraying technique to enhance the corrosion and wear performance of the NAB substrate. The XRD phase analysis evidenced the dominant presence of the WC and W2C phases in the WC-10Co-4Cr coating and the Ni2Cr3 and Si2B3 compounds in the Colmonoy-6 coating. Morphological and surface analysis showed the formation of the coatings with roughness values of Ra = 4.9 ± 0.9 µm for Colmonoy-6 and Ra = 6.8 ± 1.1 µm for WC-10Co-4Cr coatings. The electrochemical measurement in a 3.5 wt.% NaCl solution revealed that applying WC-10Co-4Cr and Colmonoy-6 HVOF coatings improved the corrosion resistance of the NAB substrate by one order of magnitude. This improvement was more significant for Colmonoy-6 coating due to the presence of electrochemically nobler compounds containing Cr and Ni. Wear measurements obtained by pin-on-disk wear test and morphological analysis of the worn path showed the lowest friction coefficient and highest wear resistance for the WC-10Co-4Cr coating followed by Colmonoy-6 coating. The superior wear performance of the WC-10Co-4Cr coating was attributed to its comprehensive mechanical properties with a Vickers hardness of 1152 ± 25 HV30, while the hardness for Colmonoy-6 and NAB substate was 789 ± 65 and 164 ± 5 HV30, respectively.

Graphical Abstract

Similar content being viewed by others

References

Q.N. Song, N. Xu, X. Jiang, Y. Liu, Y. Tong, J.S. Li et al., Effect of Sulfide Concentration on the Corrosion and Cavitation Erosion Behavior of a Manganese-Aluminum Bronze in 3.5% NaCl Solution, J. Mater. Eng. Perform., 2019, 28, p 4053–4064. https://doi.org/10.1007/s11665-019-04150-8

S. Palani, P. Lakshmanan, and R. Kaliyamurthy, Experimental Investigations of Electrochemical Micromachining of Nickel Aluminum Bronze Alloy, Mater. Manuf. Process., 2020 https://doi.org/10.1080/10426914.2020.1813888

I. Richardson, Guide to Nickel Aluminium Bronze for Engineers, Copper Development Association Publication No. 222, 2016, p. 100

M.E. Moussa, M.A. Waly, and M. Amin, Effect of High Intensity Ultrasonic Treatment on Microstructural Modification and Hardness of a Nickel-Aluminum Bronze Alloy, J. Alloys Compd., 2018, 741, p 804–813. https://doi.org/10.1016/j.jallcom.2018.01.218

R. Manikandan, S.P. Kumaresh Babu, M. Murali, and A. Vallimanalan, A Study of Corrosion Enhanced Erosion in Nickel Aluminium Bronze with Niobium and Yttrium, Mater. Today Proc., 2019 https://doi.org/10.1016/j.matpr.2019.10.083

Q. Luo, Q. Zhang, Z. Qin, Z. Wu, B. Shen, L. Liu et al., The Synergistic Effect of Cavitation Erosion and Corrosion of Nickel-Aluminum Copper Surface Layer on Nickel-Aluminum Bronze Alloy, J. Alloys Compd., 2018, 747, p 861–868. https://doi.org/10.1016/j.jallcom.2018.03.103

P. Parameswaran, A. Godwin Antony, S. Dinesh, and K. Radhakrishnan, Experimental Study on Mechanical and Corrosion Characteristics of NAB Alloy with the Addition of Chromium, Materials Today: Proceedings, Vol. 5, Elsevier, Amterdam, 2018, p 8089–8094. https://doi.org/10.1016/j.matpr.2017.11.495

M.B. Nandakumar, K.G. Sudhakar, H. Natu, and G.B. Jagadish, Experimental Investigation of Slurry Erosion Characteristics of Laser Treated Nickel Aluminum Bronze, Mater. Today Proc., 2018, 5, p 2641–2649. https://doi.org/10.1016/j.matpr.2018.01.044

S. Mehrazi, A.J. Moran, J.L. Arnold, R.G. Buchheit, and R.S. Lillard, The Electrochemistry of Copper Release from Stainless Steels and Its Role in Localized Corrosion, J. Electrochem. Soc., 2018, 165, p C860–C868. https://doi.org/10.1149/2.0071813jes

S. Siva, S. Sampathkumar, and J. Sudha, Microstructure and Mechanical Properties of Exothermic-Reaction-Assisted Friction-Stir-Welded Nickel-Aluminum Bronze Alloy, J. Mater. Eng. Perform., 2019, 28, p 2256–2270. https://doi.org/10.1007/s11665-019-03968-6

S. Thapliyal and D.K. Dwivedi, Study of the Effect of Friction Stir Processing of the Sliding Wear Behavior of Cast NiAl Bronze: A Statistical Analysis, Tribol. Int., 2016, 97, p 124–135. https://doi.org/10.1016/j.triboint.2016.01.008

W. Lu, W. Zhai, P. Zhang, M. Zhou, X. Liu, and L. Zhou, Effect of Different Levels of Free Water in Oil on the Fretting Wear of Nickel-Aluminum Bronze Based Composites, Wear, 2017, 390–391, p 376–384. https://doi.org/10.1016/j.wear.2017.09.007

Y. Li, T.L. Ngai, and W. Xia, Mechanical, Friction and Wear Behaviors of a Novel High-Strength Wear-Resisting Aluminum Bronze, Wear, 1996, 197, p 130–136. https://doi.org/10.1016/0043-1648(95)06890-2

W. Zhai, W. Lu, P. Zhang, M. Zhou, X. Liu, and L. Zhou, Microstructure, Mechanical and Tribological Properties of Nickel-Aluminium Bronze Alloys Developed Via Gas-Atomization and Spark Plasma Sintering, Mater. Sci. Eng. A, 2017, 707, p 325–336. https://doi.org/10.1016/j.msea.2017.09.047

S. Bharti, N.D. Ghetiya, and K.M. Patel, A Review on Manufacturing the Surface Composites by Friction Stir Processing, Mater. Manuf. Process., 2020 https://doi.org/10.1080/10426914.2020.1813897

S. Mohan and A. Mohan, Wear, Friction and Prevention of Tribo-Surfaces by Coatings/Nanocoatings, Elsevier, Amsterdam, 2014. https://doi.org/10.1016/B978-0-85709-211-3.00001-7

K.-S. Park, and S. Kim, Corrosion and Corrosion Fatigue Characteristics of Cast NAB Coated with NAB by HVOF Thermal Spray, J. Electrochem. Soc., 2011, 158, p C335. https://doi.org/10.1149/1.3622343

M. Koul and J. Gaies, An Environmentally Assisted Cracking Evaluation of UNS C64200 (Al–Si–Bronze) and UNS C63200 (Ni–Al–Bronze), J. Fail. Anal. Prevent., 2013, 13, p 8–19. https://doi.org/10.1007/s11668-012-9647-0

J. Stokes and L. Looney, FEA of Residual Stress During HVOF Thermal Spraying, J. Mater. Eng. Perform., 2009, 18, p 21–25. https://doi.org/10.1007/s11665-008-9262-0

G. Singh and M. Kaur, High-Temperature Wear Behaviour of HVOF Sprayed 65% (NiCrSiFeBC)−35% (WC–Co) coating, Surf. Eng., 2019 https://doi.org/10.1080/02670844.2019.1639932

D.R. Tobergte and S. Curtis, Handbook of Thermal Spray Technology, Vol. 53, 2013. https://doi.org/10.1017/CBO9781107415324.004

S.E. Mousavi, N. Naghshehkesh, M. Amirnejad, H. Shammakhi, and A. Sonboli, Wear and Corrosion Properties of Stellite-6 Coating Fabricated by HVOF on Nickel-Aluminium Bronze Substrate, Met. Mater. Int., 2020 https://doi.org/10.1007/s12540-020-00697-7

D. Wang, B. Zhang, C. Jia, F. Gao, Y. Yu, K. Chu et al., Influence of Carbide Grain Size and Crystal Characteristics on the Microstructure and Mechanical Properties of HVOF-Sprayed WC-CoCr coatings, Int. J. Refract. Met. Hard Mater., 2017, 69, p 138–152. https://doi.org/10.1016/j.ijrmhm.2017.08.008

K. Farokhzadeh, R.M. Fillion, and A. Edrisy, The Effect of Deposition Rate on Microstructural Evolution in WC-Co-Cr Coatings Deposited by High-Velocity Oxy-Fuel Thermal Spray Process, J. Mater. Eng. Perform., 2019, 28, p 7419–7430. https://doi.org/10.1007/s11665-019-04502-4

P.R. Reinaldo and A.S.C.M. D’Oliveira, NiCrSiB Coatings Deposited by Plasma Transferred Arc on Different Steel Substrates, J. Mater. Eng. Perform., 2013, 22, p 590–597. https://doi.org/10.1007/s11665-012-0271-7

M. Gui, R. Eybel, B. Asselin, S. Radhakrishnan, and J. Cerps, Influence of Processing Parameters on Residual Stress of High Velocity Oxy-Fuel Thermally Sprayed WC-Co-Cr Coating, J. Mater. Eng. Perform., 2012, 21, p 2090–2098. https://doi.org/10.1007/s11665-012-0134-2

Q. Wang, Z. Tang, and L. Cha, Cavitation and Sand Slurry Erosion Resistances of WC-10Co-4Cr Coatings, J. Mater. Eng. Perform., 2015, 24, p 2435–2443. https://doi.org/10.1007/s11665-015-1496-z

S.W. Rukhande and W.S. Rathod, Tribological Behaviour of Plasma and HVOF-sprayed NiCrSiBFe Coatings, Surf. Eng., 2020, 36, p 745–755. https://doi.org/10.1080/02670844.2020.1730062

P. Mukhopadhyay and A. Ghosh, On Bond Wear, Grit-Alloy Interfacial Chemistry and Joint Strength of Synthetic Diamond Brazed with Ni-Cr-B-Si-Fe and Ti Activated Ag-Cu Filler Alloys, Int. J. Refract. Met. Hard Mater., 2018, 72, p 236–243. https://doi.org/10.1016/j.ijrmhm.2017.12.033

N. Jeyaprakash, C.H. Yang, and S.P. Tseng, Characterization and Tribological Evaluation of NiCrMoNb and NiCrBSiC Laser Cladding on near-Α Titanium Alloy, Int. J. Adv. Manuf. Technol., 2019 https://doi.org/10.1007/s00170-019-04755-2

A. Nouri, P.D. Hodgson, and C. Wen, Effect of Ball-Milling Time on the Structural Characteristics of Biomedical Porous Ti-Sn-Nb alloy, Mater. Sci. Eng. C, 2011, 31, p 921–928. https://doi.org/10.1016/j.msec.2011.02.011

M.J. Tobar, C. Álvarez, J.M. Amado, G. Rodríguez, and A. Yáñez, Morphology and Characterization of Laser Clad Composite NiCrBSi-WC Coatings on Stainless Steel, Surf. Coat. Technol., 2006, 200, p 6313–6317. https://doi.org/10.1016/j.surfcoat.2005.11.093

N. Jeyaprakash, C.-H. Yang, and S.-P. Tseng, Wear Tribo-Performances of Laser Cladding Colmonoy-6 and Stellite-6 Micron Layers on Stainless Steel 304 Using Yb:YAG Disk Laser, Met. Mater. Int., 2019 https://doi.org/10.1007/s12540-019-00526-6

H. Zhang, Y. Shi, M. Kutsuna, and G.J. Xu, Laser Cladding of Colmonoy 6 Powder on AISI316L Austenitic Stainless Steel, Nuclear Eng. Des., 2010, 240, p 2691–2696. https://doi.org/10.1016/j.nucengdes.2010.05.040

V. Shrivastava, G. Kumar, and I.B. Singh, Heat Treatment Effect on the Microstructure and Corrosion Behavior of Al-6061 alloy with Influence of a nanoalumina Reinforcement in 3.5% NaCl solution, J. Alloys Compd., 2019, 775, p 628–38. https://doi.org/10.1016/j.jallcom.2018.10.111

X. Liu, J. Kang, W. Yue, Z. Fu, L. Zhu, D. She et al., Performance Evaluation of HVOF Sprayed WC-10Co4Cr Coatings Under Slurry Erosion, Surf. Eng., 2019, 35, p 816–825. https://doi.org/10.1080/02670844.2019.1568661

H. Masoumi, S.M. Safavi, and M. Salehi, Grinding Force, Specific Energy and Material Removal Mechanism in Grinding of HVOF-Sprayed WC–Co–Cr Coating, Mater. Manuf. Process., 2014, 29, p 321–330. https://doi.org/10.1080/10426914.2013.872261

L. Rovatti, N. Lecis, D. Dellasega, V. Russo, and E. Gariboldi, Influence of Aging in the Temperature Range 250–350°C on the Tribological Performance of a WC-CoCr Coating produced by HVOF, Int. J. Refract. Met. Hard Mater., 2018, 75, p 218–224. https://doi.org/10.1016/j.ijrmhm.2018.04.017

K. Arunkarthikeyan, K. Balamurugan, and P.M.V. Rao, Studies on Cryogenically Treated WC-Co insert at Different Soaking Conditions, Mater. Manuf. Process., 2020, 35, p 545–555. https://doi.org/10.1080/10426914.2020.1726945

L. Hong, H. Zhang, Q. Tang, J. Wen, and P. Dai, High Temperature Oxidation Behavior of Al0.5CrCoFeNi High Entropy Alloy, Intermetallics, 2015, 44, p 424–8. https://doi.org/10.1016/j.intermet.2018.04.006

Q. Wang, S. Luo, S. Wang, H. Wang, and C.S. Ramachandran, Wear, Erosion and Corrosion Resistance of HVOF-Sprayed WC and Cr3C2 Based Coatings for Electrolytic Hard Chrome Replacement, Int. J. Refract. Met. Hard Mater., 2019, 81, p 242–252. https://doi.org/10.1016/j.ijrmhm.2019.03.010

H. Vashishtha, R.V. Taiwade, and S. Sharma, Effect of Acetic Acid on Corrosion Behavior of AISI 201, 304 and 430 stainless steels, Int. J. Mater. Res., 2017, 108, p 406–415. https://doi.org/10.3139/146.111493

M. Jafari, M.H. Enayati, M. Salehi, S.M. Nahvi, and C.G. Park, Comparison Between Oxidation Kinetics of HVOF Sprayed WC–12Co and WC–10Co–4Cr Coatings, Int. J. Refract. Met. Hard Mater., 2013, 41, p 78–84. https://doi.org/10.1016/j.ijrmhm.2013.02.006

ASTM B148-18, Standard Specification for Aluminum-Bronze Sand Castings, ASTM International, West Conshohocken, PA, 2018, https://www.astm.org. https://doi.org/10.1520/B0148-18

L. Ding, H. Torbati-Sarraf, and A. Poursaee, The Influence of the Sandblasting as a Surface Mechanical Attrition Treatment on the Electrochemical Behavior of Carbon Steel in Different pH Solutions, Surf. Coat. Technol., 2018, 352, p 112–119. https://doi.org/10.1016/j.surfcoat.2018.08.013

Coating, Thermal Spray High Velocity Oxygen/Fuel Process. AMS2447D, n.d.

ASTM E2109-01, Standard Test Methods for Determining Area Percentage Porosity in Thermal Sprayed Coatings, ASTM International, West Conshohocken, PA, 2014, https://www.astm.org. https://doi.org/10.1520/E2109-01R14

R.Q. Guo, C. Zhang, Y. Yang, Y. Peng, and L. Liu, Corrosion and Wear Resistance of a Fe-Based Amorphous Coating in Underground Environment, Intermetallics, 2012, 30, p 94–99. https://doi.org/10.1016/j.intermet.2012.03.026

D. Fu, H. Xiong, and Q. Wang, Microstructure Evolution and Its Effect on the Wear Performance of HVOF-Sprayed Conventional WC-Co Coating, J. Mater. Eng. Perform., 2016, 25, p 4352–4358. https://doi.org/10.1007/s11665-016-2278-y

C. Park, J. Kim, and S. Kang, Effect of Cobalt on the Synthesis and Sintering of WC-Co Composite Powders, J. Alloys Compd., 2018, 766, p 564–571. https://doi.org/10.1016/j.jallcom.2018.06.367

T. Rönnhult, B. Brox, and G. Fritze, The Influence of Surface Topography on the x-ray Intensity in Electron Microprobe Analysis (EDS/WDS), Scanning, 1987, 9, p 81–87. https://doi.org/10.1002/sca.4950090205

D.E. Newbury and N.W.M. Ritchie, Is Scanning Electron Microscopy/Energy Dispersive X-ray Spectrometry (SEM/EDS) Quantitative?, Scanning, 2013, 35, p 141–168. https://doi.org/10.1002/sca.21041

N.W.M. Ritchie, D.E. Newbury, and J.M. Davis, EDS Measurements of X-Ray Intensity at WDS Precision and Accuracy Using a Silicon Drift Detector, Microsc. Microanal., 2012, 18, p 892–904. https://doi.org/10.1017/S1431927612001109

D.E. Newbury, Mistakes Encountered During Automatic Peak Identification in Low Beam Energy X-ray Microanalysis, Scanning, 2007, 29, p 137–151. https://doi.org/10.1002/sca.20009

Y. Liu, W. Liu, Y. Ma, S. Meng, C. Liu, L. Long et al., A comparative Study on Wear and Corrosion Behaviour of HVOF- and HVAF-Sprayed WC–10Co–4Cr Coatings, Surf. Eng., 2017, 33, p 63–71. https://doi.org/10.1080/02670844.2016.1218194

L.M. Berger, P. Ettmayer, P. Vuoristo, T. Mäntylä, and W. Kunert, Microstructure and Properties of WC-10%Co-4% Cr Spray Powders and Coatings: Part 1 Powder characterization, J. Therm. Spray Technol., 2001, 10, p 311–325. https://doi.org/10.1361/105996301770349402

V.A.D. Souza and A. Neville, Mechanisms and Kinetics of WC-Co-Cr High Velocity Oxy-Fuel Thermal Spray Coating Degradation in Corrosive Environments, J. Therm. Spray Technol., 2006, 15, p 106–117. https://doi.org/10.1361/105996306X92677

Y. Qiao, Y.R. Liu, and T.E. Fischer, Sliding and Abrasive Wear Resistance of Thermal-Sprayed WC-Co Coatings, J. Therm. Spray Technol., 2001, 10, p 118–125. https://doi.org/10.1361/105996301770349583

H. Torbati-Sarraf, S.A. Torbati-Sarraf, A. Poursaee, and T.G. Langdon, Electrochemical Behavior of a Magnesium ZK60 Alloy Processed by High-Pressure Torsion, Corros. Sci., 2019, 154, p 90–100. https://doi.org/10.1016/j.corsci.2019.04.006

S. Mahdavi and S.R. Allahkaram, Characteristics of Electrodeposited Cobalt and Titania Nano-Reinforced Cobalt Composite Coatings, Surf. Coat. Technol., 2013, 232, p 198–203. https://doi.org/10.1016/j.surfcoat.2013.05.007

S. Hong, Y. Wu, Y. Zheng, B. Wang, W. Gao, and J. Lin, Microstructure and Electrochemical Properties of Nanostructured WC-10Co-4Cr Coating Prepared by HVOF Spraying, Surf. Coat. Technol., 2013, 235, p 582–588. https://doi.org/10.1016/j.surfcoat.2013.08.029

H. Torbati-Sarraf, I. Ghamarian, B. Poorganji, and S.A. Torbati-Sarraf, An Investigation on the Role of Crystallographic Texture on Anisotropic Electrochemical Behavior of a Commercially Pure Nickel Manufactured by Laser Powder Bed Fusion (L-PBF) Additive Manufacturing, Electrochim. Acta, 2020, 354, 136694. https://doi.org/10.1016/j.electacta.2020.136694

A. Toosinezhad, M. Alinezhadfar, and S. Mahdavi, Cobalt/Graphene Electrodeposits: Characteristics, Tribological Behavior, and Corrosion Properties, Surf. Coat. Technol., 2020, 385, 125418. https://doi.org/10.1016/j.surfcoat.2020.125418

M.H. Johar, H. Torbati-Sarraf, M. Ahangari, and M. Saremi, Inhibiting effect of Benzotriazole on the Stress Corrosion Cracking of Cu-27%Ni Cupronickel and Cu-30%Zn Brass in Mattsson’s Solution, Mater. Lett., 2021, 293, 129735. https://doi.org/10.1016/j.matlet.2021.129735

M. Takeda, N. Morihiro, R. Ebara, Y. Harada, R. Wang, and M. Kido, Corrosion Behavior of Thermally Sprayed WC Coating in Na2SO4 Aqueous Solution, Mater. Trans., 2002, 43, p 2860–2865. https://doi.org/10.2320/matertrans.43.2860

A. Human, B. Roebuck, and H. Exner, Electrochemical Polarisation and Corrosion Behaviour of Cobalt and Co(W, C) Alloys in 1 N Sulphuric Acid, Mater. Sci. Eng. A, 1998, 241, p 202–210. https://doi.org/10.1016/S0921-5093(97)00492-9

A.M. Human, and H.E. Exner, Electrochemical Behaviour of Tungsten-Carbide Hardmetals, Mater. Sci. Eng. A, 1996, 209, p 180–191. https://doi.org/10.1016/0921-5093(95)10137-3

S. Lillard, D.M. Salgado, and S. Mehrazi, A One Dimensional Crevice Experiment for Determining the Critical Factors Contributing to Crevice Corrosion Stability and Repassivation, ECS Meeting Abstracts, 2018 https://doi.org/10.1149/MA2018-02/11/619

R.S. Lillard and S. Mehrazi, Quantifying Alloy 625 Crevice Corrosion Using an Image Differencing Technique: Part III. The Transition from Diffusion to Activation Control and the Implications for the Measured Electrochemical Potentials, J. Electrochem. Soc., 2021, 168(2), p 021511. https://doi.org/10.1149/1945-7111/abe47b

M.E. Orazem, N. Pébère, B. Tribollet, J.E. Soc, M.E. Orazem et al., Enhanced Graphical Representation of Electrochemical Impedance Data Service Enhanced Graphical Representation of Electrochemical, J. Electrochem. Soc., 2006, 153, p 128–136. https://doi.org/10.1149/1.2168377

H. Hassannejad, M. Moghaddasi, E. Saebnoori, and A.R. Baboukani, Microstructure, deposition mechanism and corrosion behavior of nanostructured cerium oxide conversion coating modified with chitosan on AA2024 aluminum alloy, J. Alloys Compd., 2017, 725, p 968–975. https://doi.org/10.1016/j.jallcom.2017.07.253

A. Toosinezhad, M. Alinezhadfar, and S. Mahdavi, Cobalt / graphene electrodeposits: Characteristics, tribological behavior, and corrosion properties, Surf. Coat. Technol., 2020, 385, 125418. https://doi.org/10.1016/j.surfcoat.2020.125418

S. Hong, Y. Wu, W. Gao, J. Zhang, Y. Zheng, and Y. Zheng, Slurry Erosion-Corrosion Resistance and Microbial Corrosion Electrochemical Characteristics of HVOF Sprayed WC-10Co-4Cr Coating for Offshore Hydraulic Machinery, Int. J. Refract. Met. Hard Mater., 2018, 74, p 7–13. https://doi.org/10.1016/j.ijrmhm.2018.02.019

J.B. Cheng, X.B. Liang, Z.H. Wang, and B.S. Xu, Dry Sliding Friction and Wear Properties of Metallic Glass Coating and Martensite Stainless Coating, Tribol. Int., 2013, 60, p 140–146. https://doi.org/10.1016/j.triboint.2012.11.010

H. Wang, X. Wang, X. Song, X. Liu, and X. Liu, Sliding Wear Behavior of Nanostructured WC-Co-Cr Coatings, Appl. Surf. Sci., 2015, 355, p 453–460. https://doi.org/10.1016/j.apsusc.2015.07.144

M. Xie, S. Zhang, and M. Li, Comparative Investigation on HVOF Sprayed Carbide-Based Coatings, Appl. Surf. Sci., 2013, 273, p 799–805. https://doi.org/10.1016/j.apsusc.2013.03.010

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Moghaddasi, M., Bozorg, M., Aghaie, E. et al. Corrosion and Wear Analysis of High-Velocity Oxy-Fuel Sprayed WC-10Co-4Cr and Colmonoy-6 Coatings on Nickel-Aluminum Bronze Alloy Substrate. J. of Materi Eng and Perform 30, 7564–7576 (2021). https://doi.org/10.1007/s11665-021-05965-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05965-0