Abstract

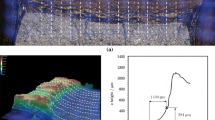

In the present study, an experimental investigation of the effects of the rolling direction on the fracture behavior of the IN625 superalloy by using the digital image correlation method is studied. The three different specimens in the different rolling directions (0°, 45°, and 90°) were interpreted using a hot-rolled IN625 plate for the tests. To evaluate the fracture behavior of the IN625, crack mouth opening displacement (CMOD), crack length, the full-field displacement of the CT specimens were measured using the digital image correlation method, and the KI, KII, and T-stress were calculated for all specimens. The scanning electron microscopy is used to evaluate fracture mechanisms and characteristics of the specimens. The results demonstrate that the fracture parameters of the IN625 superalloy can be affected by the rolling direction and specimen B has a greater CMOD value than other specimens. Also, the SIFs and T-stress increased at first and then decreased by increasing the crack length for all specimens. Furthermore, the fractography showed that a combination of ductile fracture dimples and quasi-cleavage facets, specific to the equiaxed Ni-based superalloy, have occurred in all specimens.

Similar content being viewed by others

References

B. Salehnasab, E. Poursaeidi, S.A. Mortazavi and G.H. Farokhian, Hot Corrosion Failure in the First Stage Nozzle of a Gas Turbine Engine, Eng. Fail. Anal., 2016, 60, p 316–325.

J. Wang, X. Hu, K. Yuan, W. Meng and P. Li, Impact Resistance Prediction of Superalloy Honeycomb using Modified Johnson-Cook Constitutive Model and Fracture Criterion, Int. J. Impact Eng, 2019, 131, p 66–77.

P. Wang, B. Zhang, C.C. Tan, S. Raghavan, Y.-F. Lim, C.-N. Sun, J. Wei and D. Chi, Microstructural Characteristics and Mechanical Properties of Carbon Nanotube Reinforced Inconel 625 Parts Fabricated by Selective Laser Melting, Mater. Des., 2016, 112, p 290–299.

C. Li, R. White, X.Y. Fang, M. Weaver and Y.B. Guo, Microstructure Evolution Characteristics of Inconel 625 Alloy from Selective Laser Melting to Heat Treatment, Mater. Sci. Eng. A, 2017, 705, p 20–31.

Z. Wang, A.D. Stoica, D. Ma and A.M. Beese, Diffraction and Single-Crystal Elastic Constants of Inconel 625 at Room and Elevated Temperatures Determined by Neutron Diffraction, Mater. Sci. Eng. A, 2016, 674, p 406–412.

A.M. Ganesh Puppala, S. Sathyanarayanan, G. Rakesh Kaul, R.C. Sasikala and L.M.K. Prasad, Evaluation of Fracture Toughness and Impact Toughness of Laser Rapid Manufactured Inconel-625 Structures and their Co-Relation, Mater. Design, 2014, 59, p 509–515.

A. Masoud Mirhosseini, S. Adib Nazari, A. Maghsoud Pour, S. Etemadi Haghighi and M. Zareh, Failure Analysis of First Stage Nozzle in a Heavy-Duty Gas Turbine, Eng. Fail. Anal., 2019, 109, p 104303.

H. Kazempour-Liasi, A. Shafiei and Z. Lalegani, Failure Analysis of First and Second Stage Gas Turbine Blades, J. Fail. Anal. Prevent., 2019, 19, p 1673–1682.

S.M. Muthu, Investigations of Hot Corrosion Resistance of HVOF Coated Fe Based Superalloy A-286 in Simulated Gas Turbine Environment, Eng. Fail. Anal., 2020, 107, p 104224.

E. Poursaeidi, M. Aieneravaie, R. Bannazadeh and K. Torkashvand, Failure Analysis of a GTD-111 Turbine Blade Using Metallurgical Analysis and Fractography, J. Fail. Anal. Prev., 2019, 19(5), p 1358–1369.

B. Salehnasab and E. Poursaeidi, Mechanism and Modeling of Fatigue Crack Initiation and Propagation in the Directionally Solidified CM186 LC Blade of a Gas Turbine Engine, Eng. Fract. Mech., 2020, 225, p 106842.

L.G.I. Jandejsek, M. Šperl and D. Vavrˇík, Analysis of Standard Fracture Toughness Test Based on Digital Image Correlation Data, Eng. Fract. Mech., 2017, 182, p 607–620.

Y. Li and M. Zhou, Effect of Competing Mechanisms on Fracture Toughness of Metals with Ductile Grain Structures, Eng. Fract. Mech., 2019, 205, p 14–27.

K. Han, J. Shuai, X. Deng, L. Kong, X. Zhao and M. Sutton, The Effect of Constraint on CTOD Fracture Toughness of API X65 Steel, Eng. Fract. Mech., 2014, 124–125, p 167–181.

T. Zhang, S. Wang and W. Wang, A Unified Energy Release Rate Based Model to Determine the Fracture Toughness of Ductile Metals from Unnotched Specimens, Int. J. Mech. Sci., 2019, 150, p 35–50.

A. International, "ASTM E1820-18ae1, Standard Test Method for Measurement of Fracture Toughness," 2018

B. Lin, S. Alshammrei, T. Wigger and J. Tong, Characterisation of Fatigue Crack Tip Field in the Presence of Significant Plasticity, Theoret. Appl. Fract. Mech., 2019, 103, p 102298.

I. Yamaguchi, A Laser-Speckle Strain Gauge, J. Phys. E Sci. Instrum., 1981, 14(11), p 1270–1273.

S. Roux, J. Réthoré and F. Hild, Digital Image Correlation and Fracture: an Advanced Technique for Estimating Stress Intensity Factors of 2D and 3D Cracks, J. Phys. D Appl. Phys., 2009, 42(21), p 214004.

Z.L. Xie, H.F. Zhou, L.J. Lu and Z.A. Chen, An Investigation into Fracture Behavior of Geopolymer Concrete with Digital Image Correlation Technique, Constr. Build. Mater., 2017, 155, p 371–380.

K. Fujita and A. Yoshida, The Effect of Changing the Rolling Direction on the Rolling Contact Fatigue Lives of Annealed and Case-Hardened Steel Rollers, Wear, 1977, 43(3), p 315–327.

W.R. Tyfour and J.H. Beynon, The Effect of Rolling Direction Reversal on Fatigue Crack Morphology and Propagation, Tribol. Int., 1994, 27(4), p 273–282.

D. Rahmatabadi, M. Pahlavani, A. Bayati, R. Hashemi and J. Marzbanrad, Evaluation of Fracture Toughness and Rupture Energy Absorption Capacity of As-Rolled LZ71 and LZ91 Mg Alloy Sheet, Mater. Res. Express, 2018, 6(3), p 036517.

S.S. Raza, T. Ahmad, M. Kamran, X. Zhang, M.A. Basit, M.U. Manzoor, A. Inam, O.M. Butt and M. Abrar, Effect of Hot Rolling on Microstructures and Mechanical Properties of Ni Base Superalloy, Vacuum, 2020, 174, p 109204.

S. İriç and A.O. Ayhan, Dependence of Fracture Toughness on Rolling Direction in Aluminium 7075 Alloys, Acta Phys. Pol. A, 2017, 132(3), p 892–895.

G. Lesiuk, B. Rymsza, J. Rabiega, J.A.F.O. Correia, A.M.P. De Jesus and R. Calcada, Influence of Loading Direction on the Static and Fatigue Fracture Properties of the Long Term Operated Metallic Materials, Eng. Fail. Anal., 2019, 96, p 409–425.

I. Topic, H.W. Höppel and M. Göken, Influence of Rolling Direction on Strength and Ductility of Aluminium and Aluminium Alloys Produced by Accumulative Roll Bonding, J. Mater. Sci., 2008, 43(23), p 7320–7325.

R.B. Figueiredo and T.G. Langdon, Influence of Rolling Direction on Flow and Cavitation in a Superplastic Magnesium Alloy Processed by Equal-Channel Angular Pressing, Mater. Sci. Eng. A, 2012, 556, p 211–220.

R. Uscinowicz, The Effect of Rolling Direction on the Creep Process of Al–Cu Bimetallic Sheet, Mater. Des., 2013, 49, p 693–700.

H. Zhang, G. Huang, H.J. Roven, L. Wang and F. Pan, Influence of Different Rolling Routes on the Microstructure Evolution and Properties of AZ31 Magnesium Alloy Sheets, Mater. Des., 2013, 50, p 667–673.

W.C. Lee and Z.R. Liu, Effects of Specimen Width and Rolling Direction on the Mechanical Properties of Beryllium Copper Alloy C17200, IOP Conf. Series Mater. Sci. Eng., 2015, 103, p 012051.

L.M. Najib, A. Alisibramulisi, N.M. Amin, I.A.A. Bakar, S. Hasim, The Effect of Rolling Direction to the Tensile Properties of AA5083 Specimen, InCIEC 2014, R. Hassan, M. Yusoff, A. Alisibramulisi, N. Mohd Amin, Z. Ismail Eds., 2015//, 2015 (Singapore), Springer Singapore, pp 779-787

W. Khraisat, W. Abu Jadayil, Y. Al-Zain and S.E. Musmar, The Effect of Rolling Direction on the Weld Structure and Mechanical Properties of DP 1000 steel, Cogent Eng., 2018, 5(1), p 1491019.

P. Ganesh, R. Kaul, C.P. Paul, P. Tiwari, S.K. Rai, R.C. Prasad and L.M. Kukreja, Fatigue and Fracture Toughness Characteristics of Laser Rapid Manufactured Inconel 625 Structures, Mater. Sci. Eng. A, 2010, 527(29), p 7490–7497.

D. Martelo, D. Sampath, A. Monici, R. Morana and R. Akid, Correlative Analysis of Digital Imaging, Acoustic Emission, and Fracture Surface Topography on Hydrogen Assisted Cracking in Ni-alloy 625+, Eng. Fract. Mech., 2019, 221, p 106678.

Y.-C. Zhang, W. Jiang, S.-T. Tu, X.-C. Zhang, Y.-J. Ye and R.-Z. Wang, Experimental Investigation and Numerical Prediction on Creep Crack Growth Behavior of the Solution Treated Inconel 625 Superalloy, Eng. Fract. Mech., 2018, 199, p 327–342.

B. Bahrami, M.R. Ayatollahi and A.R. Torabi, Application of Digital Image Correlation Method for Determination of Mixed Mode Stress Intensity Factors in Sharp Notches, Opt. Lasers Eng., 2020, 124, p 105830.

M. Vormwald, Y. Hos, J.L.F. Freire, G.L.G. Gonzáles and J.G. Díaz, Crack tip Displacement Fields Measured by Digital Image Correlation for Evaluating Variable Mode-Mixity during Fatigue Crack Growth, Int. J. Fatigue, 2018, 115, p 53–66.

S.H. Ju, C.Y. Chiu and B.J. Jhao, Determination of V-notch SIFs in Multi-Material Anisotropic Wedges by Digital Correlation Experiments, Int. J. Solids Struct., 2010, 47(7), p 894–900.

A.B. Patil, S.P. Toppo and R.K.P. Singh, Digital Image Correlation (DIC) Technique for Fracture Toughness Calculation of Microalloyed Steel (38MnVS6), IOP Conf. Series Mater. Sci. Eng., 2018, 422, p 012016.

M.R. Ayatollahi and M. Moazzami, Digital Image Correlation Method for Calculating Coefficients of Williams Expansion in Compact Tension Specimen, Opt. Lasers Eng., 2017, 90, p 26–33.

W.H. Kan, C. Albino, D. Dias-da-Costa, K. Dolman, T. Lucey, X. Tang, J. Cairney and G. Proust, Fracture Toughness Testing using Photogrammetry and Digital Image Correlation, MethodsX, 2018, 5, p 1166–1177.

K.G. Kodancha and S.K. Kudari, Variation of Stress Intensity Factor and Elastic T-stress Along the Crack-Front in Finite Thickness Plates, Frattura ed Integrità Strutturale, 2013, 3(8), p 45–51.

J.J. Zhang, Chapter 4 - Basic rock fracture mechanics, Applied Petroleum Geomechanicsed., J.J. Zhang, Ed., Gulf Professional Publishing, 2019, p 133-161

M.L. Williams, G.A. Laboratory, On the Stress Distribution at the Base of a Stationary Crack, Guggenheim Aeronautical Laboratory, 1957

M. Abshirini, M.Y. Dehnavi, M.A. Beni and N. Soltani, Interaction of Two Parallel U-notches with Tip Cracks in PMMA Plates under Tension using Digital Image Correlation, Theoret. Appl. Fract. Mech., 2014, 70, p 75–82.

J.R. Yates, M. Zanganeh and Y.H. Tai, Quantifying Crack Tip Displacement Fields with DIC, Eng. Fract. Mech., 2010, 77(11), p 2063–2076.

M.R. Ayatollahi and M. Nejati, Determination of NSIFs and Coefficients of Higher Order Terms for Sharp Notches using Finite Element Method, Int. J. Mech. Sci., 2011, 53(3), p 164–177.

ASTM, "ASTM E399-20, Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness of Metallic Materials," ASTM International 2020

F.G.L. Pereira, J.M. Lourenço, R.M.D. Nascimento and N.A. Castro, Fracture Behavior and Fatigue Performance of Inconel 625, Mater. Res., 2018 https://doi.org/10.1590/1980-5373-mr-2017-1089

N. Saini, C. Pandey, M.M. Mahapatra, H.K. Narang, R.S. Mulik and P. Kumar, A Comparative Study of Ductile-Brittle Transition Behavior and Fractography of P91 and P92 Steel, Eng. Fail. Anal., 2017, 81, p 245–253.

C. Pandey, N. Saini, M.M. Mahapatra and P. Kumar, Study of the Fracture Surface Morphology of Impact and Tensile Tested Cast and Forged (C&F) Grade 91 Steel at Room Temperature for Different Heat Treatment Regimes, Eng. Fail. Anal., 2017, 71, p 131–147.

C. Pandey, M.M. Mahapatra, P. Kumar and N. Saini, Effect of Creep Phenomena on Room-Temperature Tensile Properties of Cast & Forged P91 Steel, Eng. Fail. Anal., 2017, 79, p 385–396.

Acknowledgments

The authors would like to thank Dr. M. Moazami from Fatigue and Fracture Laboratory of Iran University of Science and Technology, Dr. A. Ardeshiri Lordejani from Politecnico di Milano University for provided expertise that greatly assisted the research. Also, the first author would like to express his great appreciation to Ms. Z. Khoshkhou-Gilavaei from the University of Tehran for editorial helps that greatly improved the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Salehnasab, B., Zarifpour, D., Marzbanrad, J. et al. An Investigation into the Fracture Behavior of the IN625 Hot-Rolled Superalloy. J. of Materi Eng and Perform 30, 7171–7184 (2021). https://doi.org/10.1007/s11665-021-05895-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05895-x