Abstract

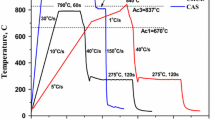

The dual-phase steel (martensite (M)/ferrite (F)) samples with different phase content were dynamic loaded simultaneously by one-stage light gas gun. The velocity of free surface particles was measured by Doppler pin system (DPS) during the loading experiment. The soft recovered samples were investigated with optical microscopy, nanoindentation, and EBSD techniques to study the effect of the phase content on dynamic damage evolution in dual-phase steel. The results show that the sample two (1000°C/60 min + 780°C/30 min+quenching) has a higher M area percentage (77.2%), larger M size, and smaller number of M and less M/F interfaces compared with the sample one (1000°C/60 min + 740°C/30 min+quenching, with M area percentage of 45.51%). Due to the reflection and transmission of shock wave at M/F interface, tensile stress will be generated inside M with higher shock impedance. Under the same dynamic loading conditions, the more M/F interface means the greater the probability of void nucleation inside M. Thus the sample two with less M/F interfaces has lower nucleation density and lower spallation strength. The microcrack propagation resistance increases with the increase in the area percentage of M and the size of M, which results in the lower damage evolution rate of the sample two. Meanwhile, the size of M will affect the direction of microcracks propagation. Each M with larger size in the sample two is composed of several prior austenite (A) grains, and the orientation of the martensite packets in prior A grains is very different. Therefore, the microcrack propagation in the sample two is limited to different regions, the direction of microcracks propagation is easy to be deflected.

Similar content being viewed by others

References

A.A. Griffith, The Phenomenon of Repture and Flow in Solids, Philos. Trans. R. Soc. Lond., 1921, A221, p 163–197.

L. Davison and R.A. Graham, Shock Compression of Solids, Phys. Rep., 1979, 55(4), p 255–379.

D.R. Curran, L. Seaman and D.A. Shockley, Dynamic Failure of Solids, Phys. Rep., 1987, 147, p 253–388.

M.A. Meyers, Dynamic Behavior of Materials, Wiley, New York, 1994.

T.H. Antoun, L. Seaman, D.R. Curran, G.I. Kanel, S.V. Razorenov and A.V. Utkin, Spall Fracture, Springer, New York, 2003.

S. Christy, H.R. Pak and M.A. Meyers, Metallurgical Applications of Shock-Wave and High-Strain-Rate Phenomena, Marcel Dekker, New York, 1986.

J.P. Escobedo, D. Denniskoller, E.K. Cerreta, B.M. Patterson, C.A. Bronkhorst, B.L. Hansen, D. Tonks and R.A. Lebensohn, Effects of Grain Size and Boundary Structure on the Dynamic Tensile Response of copper, J. Appl. Phys., 2011, 110, p 033513–033526.

J.P. Escobedo, E.K. Cerreta, D. Denniskoller, B.M. Patterson, R.A. Lebensohn and C.A. Bronkhorst, Effects of Microstructure and Shock Loading Conditions on the Damage Behavior of Polycrystalline Copper, EPJ Web Conf., 2012, 26, p 02008.

S. Razorenov, G. Kanel, A. Savinykh and V. Fortov, Large Tensions and Strength of IRON in Different Structure States, AIP Conf. Proc., 2006, 845, p 650–653.

K. Mackenchery, R.R. Valisetty, R.R. Namburu, A. Stukowski, A.M. Rajendran and A.M. Dongare, Dislocation Evolution and Peak Spall Strengths in Single Crystal and Nanocrystalline Cu, J. Appl. Phys., 2016, 119, p 817–822.

J.W. Wilkerson and K.T. Ramesh, Unraveling the Anomalous Grain Size Dependence of Cavitation, Phys. Rev. Lett., 2016, 117, p 21.

A.G. Perezbergquist, J.P. Escobedo, C.P. Trujillo, E.K. Cerreta, G.T. Gray III. and C. Brandl, The Role of the Structure of Grain Boundary Interfaces During Shock Loading, AIP Conf. Proc., 2012, 1426, p 1359–1362.

Y. Yang, Z.Q. Peng, X.Z. Chen, Z.L. Guo, T.G. Tang, H.B. Hu and Q.M. Zhang, Spall Behaviors of High Purity Copper Under Sweeping Detonation, Mater. Sci. Eng. A, 2016, 651, p 636–645.

S.J. Fensin, J.P. Escobedo-Diaz, C. Brandl, E.K. Cerreta, G.T. Gray III., T.C. Germann and S.M. Valone, Effect of Loading Direction on Grain Boundary Failure Under Shock Loading, Acta Mater., 2014, 64, p 113–122.

A.D. Brown, L. Wayne, Q. Pham, K. Krishnan, P. Peralta, S.N. Luo, B.M. Patterson, S. Greenfield, D. Byler, K.J. McClellan, A. Koskelo, R. Dickerson and X.H. Xiao, Microstructural Effects on Damage Nucleation in Shock-Loaded Polycrystalline Copper Metal, Metall. Mater. Trans. A, 2015, 46, p 4539–4547.

K. Krishnan, A.D. Brown, L. Wayne, J. Vo, S. Opie, H. Lim, P. Peralta, S.N. Luo, D. Byler, K.J. McClellan, A. Koskelo and R. Dickerson, Three-Dimensional Characterization and Modeling of Microstructural Weak Links for Spall Damage in FCC Metals, Metall. Mater. Trans. A, 2015, 46, p 4527–4538.

S.J. Fensin, S.M. Valone, E.K. Cerreta, J.P. Escobedodiaz, G.T. Gray III., K. Kang and J. Wang, Effect of Grain Boundary Structure on Plastic Deformation During Shock Compression Using Molecular Dynamics, Model. Simul. Mater. Sci. Eng., 2012, 21, p 1–12.

L. Wayne, K. Krishnan, S. DiGiacomo, N. Kovvali, P. Peralta, S.N. Luo, S. Greenfield, D. Byler, D. Paisley, K.J. McClellan, A. Koskelo and R. Dickerson, Statistics of Weak Grain Boundaries for Spall Damage in Polycrystalline Copper, Scr. Mater., 2010, 63, p 1065–1068.

P. Peralta, S. DiGiacomo, S. Hashemian, S.N. Luo, D. Paisley, R. Dickerson, E. Loomis, D. Byler and K.J. Mcclellan, Characterization of Incipient Spall Damage in Shocked Copper Multicrystals, Int. J. Damage Mech., 2009, 18, p 393–413.

Y. Yang, J.X. Chen, Z.Q. Peng, Z.L. Guo, T.G. Tang, H.B. Hu and Y.N. Hu, X-ray Quantitative Analysis on Spallation Response in High Purity Copper Under Sweeping Detonation, Mater. Sci. Eng. A, 2016, 667, p 54–60.

Y. Yang, J.X. Chen, Z.L. Guo, T.G. Tang, H.B. Hu and Y.N. Fu, 3-D Characterization of Incipient Spallation Response in Cylindrical Copper Under Sweeping Detonation, J. Mater. Res., 2017, 32, p 1499–1505.

Y. Yang, Z. Jiang, J.X. Chen, Z.L. Guo, T.G. Tang and F.B. Hu, The Characteristics of Void Distribution in Spalled High Purity Copper Cylinder Under Sweeping detonation, Philos. Mag., 2018, 98, p 752–765.

Y. Yang, Z.Q. Peng, Z.L. Guo, S.H. Luo, T.G. Tang, H.B. Hu and Q.M. Zhang, Multidimensional Study on Spall Behavior of high-Purity Copper Under Sliding Detonation, Metall. Mater. Trans. A, 2015, 46, p 4070–4077.

A.G. Perez-Bergquist and J.P. Escobedo, The Role of the Structure of Grain Boundary Interfaces During Shock Loading, AIP Conf. Proc., 2012, 142(6), p 1359–1362.

N.A. Pedrazas, D.L. Worthington, D.A. Dalton, P.A. Sherek, S.P. Steuck and H.J. Quevedo, Effects of Microstructure and Composition on Spall Fracture in Aluminum, Mater. Sci. Eng. A, 2012, 536, p 117–123.

W.Z. Han, E.K. Cerreta, N.A. Mara, I.J. Beyerlein, J.S. Carpenter and S.J. Zheng, Deformation and Failure of Shocked Bulk Cu–Nb Nanolaminates, Acta Mater., 2014, 63, p 150–161.

S.J. Fensin, E.K. Walker, E.K. Cerreta, C.P. Trujillo, D.T. Martinez and G.T. Gray III., Dynamic Failure in Two-Phase Materials, J. Appl. Phys., 2015, 118, p 235305.

S.J. Fensin, D.R. Jones, E.K. Walker, A. Farrow, S.D. Imhoff, K. Clarke, C.P. Trujillo, D.T. Martinez, G.T. Gray III. and E.K. Cerreta, The Effect of Distribution of Second Phase on Dynamic Damage, J. Appl. Phys., 2016, 120, p 085901.

S.J. Fensin, S.M. Valone, E.K. Cerreta, P.A. Rigg, G.T. Gray III, Nucleation and evolution of dynamic damage at Cu/Pb interfaces using molecular dynamics. In: Shock Compression of Condensed Matter: Conference of the American Physical Society Topical Group on Shock Compression of Condensed Matter, 2015, 1793, p 070017.

S.J. Fensin, J.P. Escobedo, G.T. Gray III., B.M. Patterson, C.P. Trujillo and E.K. Cerreta, Dynamic Damage Nucleation and Evolution in Multiphase Materials, J. Appl. Phys., 2014, 115, p 203516–203523.

Y. Yang, C. Wang, X.Z. Chen, H.B. Hu, K.G. Chen and Y.N. Fu, Effects of the Phase Interface on Spallation Damage Nucleation and Evolution in Multiphase Alloy, J. Alloy. Compd., 2018, 740, p 321–329.

Y. Yang, C. Wang, X.Z. Chen, K.G. Chen, H.B. Hu and Y.N. Fu, The Void Nucleation Mechanism Within Lead Phase During Spallation of Leaded Brass, Philos. Mag., 2018, 98(21), p 1975–1990.

Y. Yang, Z. Jiang, C. Wang, H.B. Hu, T.G. Tang, H.S. Zhang and Y.N. Fu, Effects of the Phase Interface on Initial Spallation Damage Nucleation and Evolution in Dual Phase Titanium Alloy, Mater. Sci. Eng. A, 2018, 731, p 385–393.

Y. Yang, S.J. Yang and H.M. Wang, Effects of the Phase Content on Dynamic Damage Evolution in Fe50Mn30Co10Cr10 High Entropy Alloy, J. Alloy. Compd., 2021, 851, p 156883.

Y. Yang, H.M. Wang, C. Wang and L.W. Yang, Effects of the Phase Interface on Spallation Damage Nucleation and Evolution in Dual-Phase Steel, Steel Res. Int., 2020, 91, p 1900583.

Y. Yang, S.J. Yang and H.M. Wang, Effects of Microstructure on the Evolution of Dynamic Damage of Fe50Mn30Co10Cr10High Entropy Alloy, Mater. Sci. Eng. A, 2020, 802, p 140440.

A. Bag, K.K. Ray and E.S. Dwarakadasa, Influence of Martensite Content and Morphology on Tensile and Impact Properties of High-Martensite Dual-Phase Steels, Metall. Mater. Trans. A, 1999, 30(5), p 1193–1202.

W.Y. Liu and W.S. Wang, Application of Lightweight Technology in Automobile Body (in Chinese), Automot. Eng., 2011, 2, p 50–54.

C.C. Tasan, M. Diehl, D. Yan, M. Bechtold, F. Roters, L. Schemmann et al., An Overview of Dual-Phase Steels: Advances in Microstructure-Oriented Processing and Micromechanically Guided Design, Annu. Rev. Mater. Res., 2015, 45, p 391–431.

K.T. Ramesh, High Rates and Impact Experiments, Springer Handbook of Experimental Solid Mechanics, Springer, US, 2008.

J. Weng, H. Tan, X. Wang, Y. Ma, S. Hu and X. Wang, Optical-Fiber Interferometer for Velocity Measurements with Picosecond Resolution, Appl. Phys. Lett., 2006, 89, p 4669.

Y.G. Wang and H.L. He, Study on the Dynamic Tensile Fracture and Critical Damage of 20 # steel, Chin. J. Solid Mech., 2008, 29(4), p 354–360.

W.C. Oliver and G.M. Pharr, Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7(06), p 1564–1583.

A. Ghaheri, A. Shafyei and M. Honarmand, Effects of Inter-Critical Temperatures on Martensite Morphology, Volume Fraction and Mechanical Properties of Dual-Phase Steels Obtained From Direct and Continuous Annealing Cycles, Mater. Des., 2014, 62(10), p 305–319.

H. Kitahara, R. Ueji, N. Tsuji and Y. Minamino, Crystallographic Features of Lath Martensite in Low-Carbon Steel, Acta Mater., 2006, 54(5), p 1279–1288.

L. Seaman, D.R. Curran and D.A. Shockey, Computational Models for Ductile and Brittle Fracture, J. Appl. Phys., 1976, 47(11), p 4814–4826.

E.B. Zaretsky and G.I. Kanel, Response of Copper to Shock-Wave Loading at Temperatures Up to the Melting Point, J. Appl. Phys., 2013, 114(8), p S9-73.

Y.G. Wang and H.L. He, Investigation of PRECURSOR Decay and Stress Relaxation in Shock-Compressed 20 Steel, Chin. J. High Press. Phys., 2007, 21(1), p 35–39.

C. Li, B. Li, J.Y. Huang, H.H. Ma, M.H. Zhu, J. Zhu and S.N. Luo, Spall Damage of a Mild Carbon Steel: Effects of Peak Stress, Strain Rate and Pulse Duration, Mater. Sci. Eng. A, 2016, 660, p 139–147.

C. Li, J.Y. Huang, X.C. Tang, H.W. Chai, X.H. Xiao, Z.D. Feng and S.N. Luo, Effects of Structural Anisotropy on Deformation and Damage of a Duplex Stainless Steel Under High Strain Rate Loading, Mater. Sci. Eng. A, 2017, 705, p 265–272.

S.A. Novikov, Spall Strength of Materials Under Shock Load, J. Appl. Mech. Tech. Phys., 1967, 3, p 109.

G.V. Stepanov, Spall Fracture of Metals by Elastic-Plastic Loading Waves, Probl. Strength, 1976, 8, p 66–70.

G.I. Kanel, Distortion of the Wave Profiles in an Elastoplastic Body Upon Spalling, J. Appl. Mech. Tech. Phys., 2001, 42(2), p 358–362.

J.P. Escobedo, E.N. Brown, C.P. Trujillo and G.T. Gray, The Effect of Shock-Wave Profile on Dynamic Brittle Failure, J. Appl. Phys., 2013, 113(10), p 753.

X.Y. Pei, H. Peng, H.L. He and P. Li, Study on the Effect of Peak Stress on Dynamic Damage Evolution of High Pure Copper, Acta Phys. Sin., 2015, 64(5), p 1–6.

G.I. Kanel, S.V. Razorenov, A. Bogatch, A.V. Utkin and D.E. Grady, Simulation of Spall Fracture of Aluminum and Magnesium Over a Wide Range of Load Duration and Temperature, Int. J. Impact Eng., 1997, 20, p 467–478.

S.K. Yerra, G. Martin, M. Véron, Y. Bréchet, J.D. Mithieux, L. Delannay and T. Pardoen, Ductile Fracture Initiated by Interface Nucleation in Two-Phase Elastoplastic Systems, Eng. Fract. Mech., 2013, 102, p 77–100.

N. Saeidi, F. Ashrafizadeh, B. Niroumand and F. Barlat, EBSD Study of Damage Mechanisms in a High-Strength Ferrite-Martensite Dual-Phase Steel, J. Mater. Eng. Perform., 2015, 24(1), p 53–58.

X. Liu, F. Zhong, J.X. Zhang, M.X. Zhang, M.K. Kang and Z.Q. Guo, Lattice-Parameter Variation with Carbon Content of Martensite. I. X-ray-Diffraction Experimental Study, Phys. Rev. B, 1995, 52(14), p 9970–9978.

S. Morito, H. Tanaka, R. Konishi, T. Furuhara and T. Maki, The Morphology and Crystallography of Lath martensite in Fe-C alloys, Acta Mater., 2003, 51(6), p 1789–1799.

C.M. Deng, Z.D. Li, X.J. Sun, Y. Zhou and Q.L. Yong, Influence Mechanism of High Angle Boundary on Propagation of Cleavage Cracks in Low Carbon Lath Martensite Steel, Mater. Mech. Eng., 2014, 38(6), p 20–24.

G.R. Irwin, Fracture Strengths Relative to Onset and Arrest of Crack Propagation, Proc. Am. Soc. Test. Meter., 1958, 58, p 640–657.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 51871243, 51574290), Hunan Provincial Natural Science Foundation of China (No. 2019JJ40381). All data, models, and code generated or used during the study appear in the submitted article

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, Y., Wang, H. & Wang, C. Effects of the Phase Content on Spallation Damage Behavior in Dual-Phase Steel. J. of Materi Eng and Perform 30, 5614–5624 (2021). https://doi.org/10.1007/s11665-021-05811-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05811-3