Abstract

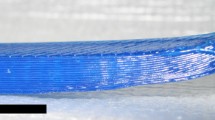

A comprehensive understanding of the 3D printing method—microstructure—material properties relationship of 3D printed parts is currently limited. In fused filament fabrication (fused deposition modeling/FDM) 3D printing technology, parts are fabricated by deposition of material layer upon layer. The printing process has a vital influence on the final quality of printed parts. Also, processing parameters control the microstructure of 3D printed components and thus, the parameters in-turn affect the component’s material properties. Experimental evaluation of this relationship is challenging, and an alternative solution is computational modeling. The computational models based on multi-physics provide deeper insights into the relationship of process-structure-property of printed parts. This chapter explores different computational models available for modeling the FDM process, computational material models for 3D printed parts and models for characterizing part’s material behavior.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Sun Q, Rizvi GM, Bellehumeur CT, Gu P (2008) Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp J 14(2):72–80

Coogan TJ, Kazmer DO (2017) Bond and part strength in fused deposition modeling. Rapid Prototyp J 23(2):414–422

Bellehumeur C, Li L, Sun Q, Gu P (2004) Modeling of bond formation between polymer filaments in the fused deposition modeling process. J Manuf Process 6(2):170–178

Das A, McIlroy C, Bortner MJ (2020) Advances in modeling transport phenomena in material–extrusion additive manufacturing: coupling momentum, heat, and mass transfer. Progress Addit Manuf. https://doi.org/10.1007/s40964-020-00137-3

Gurrala PK, Regalla SP (2014) Part strength evolution with bonding between filaments in fused deposition modelling: this paper studies how coalescence of filaments contributes to the strength of final FDM part. Virtual Phys Prototyp 9(3):141–149

Coogan TJ, Kazmer DO (2017) Healing simulation for bond strength prediction of FDM. Rapid Prototyp J 23(3):551–561

Tymrak BM, Kreiger M, Pearce JM (2014) Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater Des 58:242–246

Huang B, Singamneni S (2015) Raster angle mechanics in fused deposition modelling. J Compos Mater 49(3):363–383

Cantrell JT, Rohde S, Damiani D, Gurnani R, DiSandro L, Anton J, Young A, Jerez A, Steinbach D, Kroese C, Ifju PG (2017) Experimental characterization of the mechanical properties of 3D-printed ABS and polycarbonate parts. Rapid Prototyp J 23(4):811–824

Somireddy M, Czekanski A (2020) Anisotropic material behavior of 3D printed composite structures–material extrusion additive manufacturing. Mater Des 195:108953

Rajpurohit SR, Dave HK (2019) Analysis of tensile strength of a fused filament fabricated PLA part using an open-source 3D printer. Int J Adv Manuf Technol 101(5–8):1525–1536

Rezayat H, Zhou W, Siriruk A, Penumadu D, Babu SS (2015) Structure–mechanical property relationship in fused deposition modelling. Mater Sci Technol 31(8):895–903

Somireddy M, Singh CV, Czekanski A (2019) Analysis of the material behavior of 3D printed laminates via FFF. Exp Mech 59(6):871–881

Ning F, Cong W, Hu Y, Wang H (2017) Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: effects of process parameters on tensile properties. J Compos Mater 51(4):451–462

Li L, Sun Q, Bellehumeur C, Gu P (2002) Composite modeling and analysis for fabrication of FDM prototypes with locally controlled properties. J Manuf Process 4(2):129–141

Somireddy M, Czekanski A, Singh CV (2018) Development of constitutive material model of 3D printed structure via FDM. Mater Today Commun 15:143–152

Nasirov A, Gupta A, Hasanov S, Fidan I (2020) Three-scale asymptotic homogenization of short fiber reinforced additively manufactured polymer composites. Compos B Eng 202:108269

Somireddy M, Singh CV, Czekanski A (2020) Mechanical behaviour of 3D printed composite parts with short carbon fiber reinforcements. Eng Fail Anal 107:104232

Turner BN, Strong R, Gold SA (2014) A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp J 20(3):192–204

Turner BN, Gold SA (2015) A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp J 21(3):250–261

McIlroy C, Graham RS (2018) Modelling flow-enhanced crystallisation during fused filament fabrication of semi-crystalline polymer melts. Addit Manuf 24:323–340

Bellini A, Güçeri S, Bertoldi M (2004) Liquefier dynamics in fused deposition. J Manuf Sci Eng Trans ASME 126:237–246

Ramanath HS, Chua CK, Leong KF, Shah KD (2008) Melt flow behaviour of poly-ε-caprolactone in fused deposition modelling. J Mater Sci-Mater Med 19(7):2541–2550

Serdeczny MP, Comminal R, Mollah MT, Pedersen DB, Spangenberg J (2020) Numerical modeling of the polymer flow through the hot-end in filament-based material extrusion additive manufacturing. Addit Manuf 36:101454

Xia H, Lu J, Dabiri S, Tryggvason G (2018) Fully resolved numerical simulations of fused deposition modeling. Part I: fluid flow. Rapid Prototyp J 24(2):463–476

Comminal R, Serdeczny MP, Pedersen DB, Spangenberg J (2019) Motion planning and numerical simulation of material deposition at corners in extrusion additive manufacturing. Addit Manuf 29:100753

Serdeczny MP, Comminal R, Pedersen DB, Spangenberg J (2018) Experimental validation of a numerical model for the strand shape in material extrusion additive manufacturing. Addit Manuf 24:145–153

Xia H, Lu J, Tryggvason G (2018) Fully resolved numerical simulations of fused deposition modeling. Part II–solidification, residual stresses and modeling of the nozzle. Rapid Prototyp J 24(6):973–987

Phan DD, Swain ZR, Mackay ME (2018) Rheological and heat transfer effects in fused filament fabrication. J Rheol 62(5):1097–1107

Zhang Y, Chou YK (2006) Three-dimensional finite element analysis simulations of the fused deposition modelling process. Proc Inst Mech Eng B J Eng Manuf 220(10):1663–1671

Zhang Y, Chou K (2008) A parametric study of part distortions in fused deposition modelling using three-dimensional finite element analysis. Proc Inst Mech Eng B J Eng Manuf 222(8):959–968

Zhou Y, Nyberg T, Xiong G, Liu D (2016) Temperature analysis in the fused deposition modeling process. In: 2016 3rd international conference on information science and control engineering (ICISCE) IEEE, pp 678–682

Zhou X, Hsieh SJ, Sun Y (2017) Experimental and numerical investigation of the thermal behaviour of polylactic acid during the fused deposition process. Virtual Phys Prototyp 12(3):221–233

Parandoush P, Lin D (2017) A review on additive manufacturing of polymer-fiber composites. Compos Struct 182:36–53

Rodríguez JF, Thomas JP, Renaud JE (2003) Mechanical behavior of acrylonitrile butadiene styrene fused deposition materials modeling. Rapid Prototyp J 9(4):219–230

Somireddy M, Czekanski A (2017) Mechanical characterization of additively manufactured parts by FE modeling of mesostructure. J Manuf Mater Process 1(2):18

Chen R, Kaplan AF, Senesky DG (2020) Closed-form orthotropic constitutive model for aligned square array mesostructure. Addit Manuf 36:101463

Yuan Z, Fish J (2008) Toward realization of computational homogenization in practice. Int J Numer Meth Eng 73(3):361–380

Xia Z, Zhang Y, Ellyin F (2003) A unified periodical boundary conditions for representative volume elements of composites and applications. Int J Solids Struct 40(8):1907–1921

Anoop MS, Senthil P (2019) Homogenisation of elastic properties in FDM components using microscale RVE numerical analysis. J Braz Soc Mech Sci Eng 41(12):540

Calneryte D, Barauskas R, Milasiene D, Maskeliunas R, Neciunas A, Ostreika A, Patasius M, Krisciunas A (2018) Multi-scale finite element modeling of 3D printed structures subjected to mechanical loads. Rapid Prototyp J 24(1):177–187

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Prajapati, A.R., Rajpurohit, S.R., Somireddy, M. (2021). Computational Models: 3D Printing, Materials and Structures. In: Dave, H.K., Davim, J.P. (eds) Fused Deposition Modeling Based 3D Printing. Materials Forming, Machining and Tribology. Springer, Cham. https://doi.org/10.1007/978-3-030-68024-4_21

Download citation

DOI: https://doi.org/10.1007/978-3-030-68024-4_21

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-68023-7

Online ISBN: 978-3-030-68024-4

eBook Packages: EngineeringEngineering (R0)