Abstract

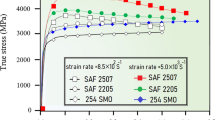

The deformation behavior of the selected stainless steels (UNS S31603, UNS S32205, UNS S32550 and UNS S32760) was evaluated at strain rates ranging between 10-2 and 10-7 s-1. Microstructural evaluation was conducted using optical and scanning electron microscopy, electron backscattered diffraction and x-ray diffraction. The total strain at fracture remained approximately constant as the strain rate increased from 10-7 to 10-3 s-1. Further increase in strain rate above 10-3 s-1 resulted in relatively lower strain. The strain rate sensitivity of each steel decreased with increasing strain. Also, the strain hardening rate and exponent of the alloys increased with decreasing strain rate. Post-deformation microstructure evaluation on UNS S31603 specimens showed slip, twinning and martensitic transformation, while the duplex alloys exhibited slip, twinning with less noticeable martensitic transformation. Fractographic examination after tensile test indicates an increase in dimple diameter with strain rate and subsequent decrease in dimple density.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

S.L. Chawla, and R.K. Gupta, Materials selection for corrosion resistance, ASM international, 2010.

P. Cunat, Alloying elements in stainless steel and other chromium-containing alloys, ICDA. (2004), p 1–24.

D. Eliezer, D.G. Chakrapani, C.J. Altstetter, and E.N. Pugh, The Influence of Austenite Stability on the Hydrogen Embrittlement and Stress- Corrosion Cracking of Stainless Steel, Metall. Trans. A., 1979, 10, p 935–941.

E. Otero, A. Pardo, M.V. Utrilla, E. Sáenz, and F.J. Perez, Influence of Microstructure on the Corrosion Resistance of AISI Type 304L and Type 316L Sintered Stainless Steels Exposed to Ferric Chloride Solution, Mater. Charact., 1995, 35, p 145–151.

C.R. de Farias Azevedo, H. Boschetti Pereira, S. Wolynec, A.F. Padilha, An Overview of the Recurrent Failures of Duplex Stainless Steels, Eng. Fail. Anal. 97 (2019), p 161–188.

R.M. Souto, I.C. Mirza Rosca, and S. González, Resistance to Localized Corrosion of Passive films on a Duplex Stainless Steel, Corrosion. 57 (2001), p 300–306.

R.N. Gunn, Duplex Stainless Steels: Microstructure, Properties and Applications, Woodhead Publishing Limited, 1997.

J.C. De Lacerda, L.C. Cândido, and L.B. Godefroid, Effect of Volume Fraction of Phases and Precipitates on the Mechanical Behavior of UNS S31803 Duplex Stainless Steel, Int. J. Fatigue., 2015, 74, p 81–87.

P. Marshall, Austenitic Stainless Steels: Microstructure and Mechanical Properties, Springer Science & Business Media, 1984.

D.M. Xu, X.L. Wan, J.X. Yu, G. Xu, and G.Q. Li, Effect of Strain Rate on Microstructures and Mechanical Properties of Fe–18Cr–8Ni Steel, Mater. Sci. Technol. (United Kingdom), 2019, 35, p 195–203.

M.G. Stout, and P.S. Follansbee, Strain Rate Sensitivity, Strain Hardening, and Yield Behavior of 304L Stainless Steel, J. Eng. Mater. Technol., 1986, 108, p 344.

Y. Estrin, and L.P. Kubin, Plastic Instabilities: Phenomenology and Theory, Mater. Sci. Eng. A., 1991, 137, p 125–134.

E. Cadoni, L. Fenu, and D. Forni, Strain Rate Behaviour in Tension of Austenitic Stainless Steel Used for Reinforcing Bars, Constr. Build. Mater., 2012, 35, p 399–407.

W.S. Lee, and H.F. Lam, Mechanical Response and Dislocation Substructure of High Strength Ni-Cr-Mo Steel Subjected to Impact Loading, J. Phys. IV JP., 1994, 4, p 307–312.

E.B. Zaretsky, and G.I. Kanel, Effect of Temperature, Strain, and Strain Rate on the Flow Stress of Aluminum Under Shock-Wave Compression, J. Appl. Phys. 112 (2012).

P.S. Follansbee, and U.F. Kocks, A Constitutive Description of the Deformation of Copper Based on the Use of the Mechanical Threshold Stress as an Internal State Variable, Acta Metall., 1988, 36, p 81–93.

S.Y. Lee, S.I. Lee, and B. Hwang, Effect of Strain Rate on Tensile and Serration Behaviors of an Austenitic Fe-22Mn-0.7C Twinning-Induced Plasticity Steel, Mater. Sci. Eng. A. 711 (2018), p 22–28.

A. Benallal, T. Borvik, A. Clausen, and O. Hopperstad, Dynamic Strain Aging, Negative Strain- Rate Sensitivity and Related Instabilities, Strain. (2003), p 160–166.

G.X. Sun, Y. Jiang, X.R. Zhang, S.C. Sun, Z.H. Jiang, W.Q. Wang, and J.S. Lian, Strain Rate and Cold Rolling Dependence of Tensile Strength and Ductility in High Nitrogen Nickel-Free Austenitic Stainless Steel Project Supported by the National Natural Science Foundations of China (Grant Nos. 51371089 and 51401083), Chinese Phys. B. 26 (2017).

F.M.F. Serafim, W.O. Alabi, I.N.A. Oguocha, A.G. Odeshi, R. Evitts, R.J. Gerspacher, and E.G. Ohaeri, Stress Corrosion Cracking Behavior of Selected Stainless Steels in Saturated Potash Brine Solution at Different Temperatures, Corros. Sci., 2021, 178, p 109025.

Unknown, Etching Specialty Alloys, (2008) 1–6. https://www.google.co.kr/%5Cnpapers3://publication/uuid/7B149A4D-2255-4F6E-A331- EFE5F5D70DE7.

E. Ohaeri, U. Eduok, and J. Szpunar, Relationship Between Microstructural Features in Pipeline Steel and Hydrogen Assisted Degradation, Eng. Fail. Anal., 2019, 96, p 496–507.

A. Seret, C. Moussa, M. Bernacki, J. Signorelli, and N. Bozzolo, Estimation of Geometrically Necessary Dislocation Density from Filtered EBSD Data by a Local Linear Adaptation of Smoothing Splines, J. Appl. Crystallogr., 2019, 52, p 548–563.

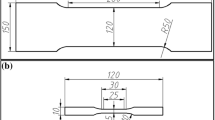

A. International, ASTM A484/A484M - 18a - Standard specification for general requirements for stainless steel bars, billets and forgings, 2005.

A. International, ASTM G49-85 - Standard practice for preparation and Use of Direct Tension Stress-Corrosion Test Specimens, 2000.

E. Bettini, U. Kivisäkk, C. Leygraf, and J. Pan, Study of Corrosion Behavior of a 2507 Super Duplex Stainless Steel: Influence of Quenched-in and Isothermal Nitrides, Int. J. Electrochem. Sci., 2014, 9, p 61–80.

Y. Jin, Annealing Twin Formation Mechanism, 2012.

V. Randle, Mechanism of Twinning-Induced Grain Boundary Engineering in Low Stacking- Fault Energy Materials, Acta Mater., 1999, 47, p 4187–4196.

J. Nomani, A. Pramanik, T. Hilditch, and G. Littlefair, Investigation on the Behavior of Austenite and Ferrite Phases at Stagnation Region in the Turning of Duplex Stainless Steel Alloys, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 47 (2016), p 3165–3177.

W. Wang, Y. Ma, M. Yang, P. Jiang, F. Yuan, and X. Wu, Strain Rate Effect on Tensile Behavior for a High Specific Strength Steel: From Quasi-Static to Intermediate Strain Rates, Metals (Basel)., 2017, 8, p 11.

R. Song, D. Ponge, D. Raabe, J.G. Speer, and D.K. Matlock, Overview of Processing, Microstructure and Mechanical Properties of Ultrafine Grained bcc Steels, Mater. Sci. Eng. A., 2006, 441, p 1–17.

M. Okayasu, and D. Ishida, Effect of Microstructural Characteristics on Mechanical Properties of Austenitic, Ferritic, and γ-α Duplex Stainless Steels, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 50 (2019), p 1380–1388.

J.W. Simmons, Influence of Nitride (Cr2N) Precipitation on the Plastic Flow Behavior of High-Nitrogen Austenitic Stainless Steel, Scr. Metall. Mater., 1995, 32, p 265–270.

S.P. Joshi, C. Eberl, B. Cao, K.T. Ramesh, and K.J. Hemker, On the Occurrence of Portevin-Le Chêtelier Instabilities in Ultrafine-Grained 5083 Aluminum Alloys, Exp. Mech., 2009, 49, p 207–218.

M. Abbadi, P. Hähner, and A. Zeghloul, On the Characteristics of Portevin-Le Chatelier Bands in Aluminum Alloy 5182 Under Stress-Controlled and Strain-Controlled Tensile Testing, Mater. Sci. Eng. A., 2002, 337, p 194–201.

E. Pink, and S. Kumar, Patterns of Serrated Flow in a Low-Carbon Steel, Mater. Sci. Eng. A., 1995, 201, p 58–64.

P. Rodriguez, Serrated Plastic Flow, Bull. Mater. Sci., 1984, 6, p 653–663.

L.P. Kubin, and Y. Estrin, Dynamic Strain Ageing and the Mechanical Response of Alloys, J. Phys., 1991, III(1), p 929–943.

Y. Nakada, and A.S. Keh, Serrated Flow in Ni-C Alloys, Acta Metall., 1970, 18, p 437–443.

R.D.K. Misra, V.S.A. Challa, P.K.C. Venkatsurya, Y.F. Shen, M.C. Somani, and L.P. Karjalainen, Interplay Between Grain Structure, Deformation Mechanisms and Austenite Stability In Phase-Reversion-Induced Nanograined/Ultrafine-Grained Austenitic Ferrous Alloy, Acta Mater., 2015, 84, p 339–348.

J.A. Lichtenfeld, M.C. Mataya, and C.J. Van Tyne, Effect of Strain Rate on Stress-Strain Behaviour of Alloy 309 and 304L{} Austenitic Stainless Steel, Metall. Mater. Trans. A., 2006, 37, p 147–161.

G.S. Langdon, and G.K. Schleyer, Unusual Strain Rate Sensitive Behaviour of AISI 316L Austenitic Stainless Steel, J. Strain Anal. Eng. Des., 2004, 39, p 71–86.

Y.N. Dastur, and W.C. Leslie, Mechanism of Work Hardening in Hadfield Manganese Steel, Metall. Trans. A, Phys. Metall. Mater. Sci. 12 A (1981), p 749–759.

M. Koyama, T. Sawaguchi, and K. Tsuzaki, Overview of Dynamic Strain Aging and Associated Phenomena in Fe – Mn – C Austenitic Steels, 58 (2018), p 1383–1395.

X. Yang, H. Guo, Z. Yao, and S. Yuan, Strain Rate Sensitivity, Temperature Sensitivity, and Strain Hardening During the Isothermal Compression of BT25y Alloy, J. Mater. Res., 2016, 31, p 2863–2875.

F. Ozturk, A. Polat, S. Toros, and R.C. Picu, Strain Hardening and Strain Rate Sensitivity Behaviors of Advanced High Strength Steels, J. Iron Steel Res. Int., 2013, 20, p 68–74.

Z. Fan, H. Mingzhi, and S. Deke, The Relationship Between the Strain-Hardening Exponent n and the Microstructure of Metals, Mater. Sci. Eng. A., 1989, 122, p 211–213.

Y.Z. Tian, L.J. Zhao, S. Chen, A. Shibata, Z.F. Zhang, and N. Tsuji, Significant Contribution of Stacking Faults to the Strain Hardening Behavior of Cu-15%Al Alloy with Different Grain Sizes, Sci. Rep., 2015, 5, p 2–10.

Y.J. Xu, D.Q. Qi, K. Du, C.Y. Cui, and H.Q. Ye, Stacking Fault Effects on Dynamic Strain Aging in a Ni-Co-Based Superalloy, Scr. Mater., 2014, 87, p 37–40.

X.Y. San, X.G. Liang, L.P. Chen, Z.L. Xia, and X.K. Zhu, Influence of Stacking Fault Energy on the Mechanical Properties in cold-Rolling Cu and Cu-Ge Alloys, Mater. Sci. Eng. A., 2011, 528, p 7867–7870.

K.T. Park, K.G. Jin, S.H. Han, S.W. Hwang, K. Choi, and C.S. Lee, Stacking Fault Energy and Plastic Deformation of Fully Austenitic High Manganese Steels: Effect of Al Addition, Mater. Sci. Eng. A., 2010, 527, p 3651–3661.

A. Grajcar, A. Kozłowska, and B. Grzegorczyk, Strain hardening behavior and microstructure evolution of high-manganese steel subjected to interrupted tensile tests, Metals (Basel). 8 (2018).

A. Bintu, G. Vincze, C.R. Picu, A.B. Lopes, J.J. Grácio, and F. Barlat, Strain Hardening Rate Sensitivity and Strain Rate Sensitivity in TWIP Steels, Mater. Sci. Eng. A., 2015, 629, p 54–59.

J. Friedel, Coldwork. Piled Up Groups, in: Dislocations, 1964, p 241–274.

K. Yvell, T.M. Grehk, P. Hedström, A. Borgenstam, and G. Engberg, Microstructure Development in a High-Nickel Austenitic Stainless Steel Using EBSD During In Situ Tensile Deformation, Mater. Charact., 2018, 135, p 228–237.

K.M. Rahman, V.A. Vorontsov, and D. Dye, The effect of grain size on the twin initiation stress in a TWIP steel, Acta Mater., 2015, 89, p 247–257.

A. Ghaderi, and M.R. Barnett, Sensitivity of Deformation Twinning to Grain Size in Titanium and Magnesium, Acta Mater., 2011, 59, p 7824–7839.

C. Herrera, D. Ponge, and D. Raabe, Design of a Novel Mn-Based 1 GPa Duplex Stainless TRIP Steel with 60% Ductility by a Reduction of Austenite Stability, Acta Mater., 2011, 59, p 4653–4664.

S. Wroński, J. Tarasiuk, B. Bacroix, A. Baczmański, and C. Braham, Investigation of Plastic Deformation Heterogeneities in Duplex Steel by EBSD, Mater. Charact., 2012, 73, p 52–60.

V. Yamakov, D. Wolf, S.R. Phillpot, and H. Gleiter, Deformation Twinning in Nanocrystalline Al by Molecular-Dynamics Simulation, Acta Mater., 2002, 50, p 5005–5020.

Y. Matsuoka, T. Iwasaki, N. Nakada, T. Tsuchiyama, and S. Takaki, Effect of Grain Size on Thermal and Mechanical Stability of Austenite in Metastable Austenitic Stainless Steel, ISIJ Int., 2013, 53, p 1224–1230.

K.T. Park, S.W. Hwang, J.H. Ji, and C.S. Lee, Static and Dynamic Deformation of Fully Austenitic High Mn Steels, Procedia Eng., 2011, 10, p 1002–1006.

Z. Li, L. Zhang, N. Sun, L. Fu, and A. Shan, Grain Size Dependence of the Serrated Flow in a Nickel Based Alloy, Mater. Lett., 2015, 150, p 108–110.

R. Alturk, S. Mates, Z. Xu, and F. Abu-Farha, Effects of Microstructure on the Strain Rate Sensitivity of Advanced Steels, Miner. Met. Mater. Ser. Part F, 2017, 6, p 243–254.

S. Harjo, N. Tsuchida, J. Abe, and W. Gong, Martensite Phase Stress and the Strengthening Mechanism in TRIP Steel by Neutron Diffraction, Sci. Rep., 2017, 7, p 2–4.

S. Lee, Y. Estrin, and B.C. De Cooman, Effect of the Strain Rate on the TRIP-TWIP Transition in Austenitic Fe-12 pct Mn-0.6 pct C TWIP STEEL, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 45 (2014), p 717–730.

S.H. Bak, S.S. Kim, and D.B. Lee, Effect of Hydrogen on Dislocation Structure and Strain- Induced Martensite Transformation In 316L Stainless Steel, RSC Adv., 2017, 7, p 27840–27845.

W. Liu, J. Lian, and S. Münstermann, Damage Mechanism Analysis of a High-Strength Dual- Phase Steel Sheet with Optimized Fracture Samples for Various Stress States and Loading Rates, Eng. Fail. Anal., 2019, 106, p 1–23.

A. Das, and S. Tarafder, Geometry of Dimples and Its Correlation with Mechanical Properties in Austenitic Stainless Steel, Scr. Mater., 2008, 59, p 1014–1017.

S. Sun, A. Zhao, and Q. Wu, Effect of Strain Rate on the Work-Hardening Rate in High-Mn Steel, Mater. Sci. Technol. (United Kingdom), 2017, 33, p 1306–1311.

Acknowledgments

The authors are grateful for the financial support provided by the International Mineral Innovation Institute (IMII) and by all participating industries in this research project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Serafim, F.M.F., Oguocha, I.N.A., Odeshi, A.G. et al. Mechanical Response of Stainless Steels at Low Strain Rate. J. of Materi Eng and Perform 30, 3771–3785 (2021). https://doi.org/10.1007/s11665-021-05671-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05671-x