Abstract

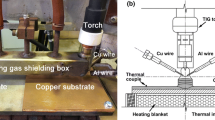

In this work, the cold metal transfer (CMT) welding technique was used to additive manufacture Cu-6.6%Al-3.2%Si alloy. A dual wire feeding approach was adopted to separately feed SAFRA CuSi3 wire and AlSi5-ER4043 wire into the molten pool. To overcome the defect of non-uniform sample height, the CMT welding head was used in the round-trip configuration to deposit the samples. The deposited samples were characterized for their (1) microstructure and (2) mechanical properties of hardness and tensile strength. Microstructural characterization was done using optical microscopy (OM), scanning electron microscopy and transmission electron microscopy. From the elemental analysis, the central region of the deposited layer was enriched in aluminum and depleted in silicon compared to the region at the border of the layer. Evaluation of the mechanical properties showed that the deposited samples had good strength and ductility. The addition of silicon and manganese effectively improved the hardness and tensile strength properties of the deposited alloy.

Similar content being viewed by others

References

J. Mohd Jani, M. Leary, A. Subic, and M.A. Gibson, A Review of Shape Memory Alloy Research, Applications and Opportunities, Mater. Des., 2014, 56, p 1078–1113. https://doi.org/10.1016/j.matdes.2013.11.084

T. Gustmann, A. Neves, U. Kühn, P. Gargarella, C.S. Kiminami, C. Bolfarini, J. Eckert, and S. Pauly, Influence of Processing Parameters on the Fabrication of a Cu-Al-Ni-Mn Shape-Memory Alloy by Selective Laser Melting, Addit. Manuf., 2016, 11, p 23–31. https://doi.org/10.1016/j.addma.2016.04.003

L.M. Dimaté Castllanos, J.J. Olaya Florez, and J.E. Alfonso Orjuela, Resistencia a la corrosión en recubrimientos Cu-Al producidos con el sistema de proyección térmica por llama, Ing. Invest., 2012, 32, p 18–23. (in Spanish)

O. Johari, and G. Thomas, Factors Affecting Dislocation Substructures in Deformed Copper, Acta Metall., 1964, 12, p 679–682. https://doi.org/10.1016/0001-6160(64)90044-6

C.X. Ren, Q. Wang, J.P. Hou, Z.J. Zhang, H.J. Yang, and Z.F. Zhang, Exploring the Strength and Ductility Improvement of Cu–Al Alloys, Mater. Sci. Eng. A, 2020 https://doi.org/10.1016/j.msea.2020.139441

O. Johari, and G. Thomas, Substructures in explosively deformed Cu and Cu-Al alloys, Acta Metall., 1964, 12, p 1153–1159. https://doi.org/10.1016/0001-6160(64)90095-1

Y.Z. Tian, L.J. Zhao, N. Park, R. Liu, P. Zhang, Z.J. Zhang, A. Shibata, Z. Zhang, and N. Tsuji, Revealing the Deformation Mechanisms of Cu–Al Alloys with High Strength and Good Ductility, Acta Mater., 2016, 110, p 61–72. https://doi.org/10.1016/j.actamat.2016.03.015

H. Yuan, C. Yiqing, L. Li, H. Huan-dong, and Z. Ziang, Microstructure and Properties of Al/Cu Bimetal in Liquid-Solid Compound Casting Process, Trans. Nonferrous Met. Soc. China, 2016, 26, p 1555–1563. https://doi.org/10.1016/S1003-6326(16)64261-9

Y. Wang, X. Chen, and S.V. Konovalov, Additive Manufacturing Based on Welding Arc: A Low-Cost Method, J Surf. Invest., 2017, 11, p 1317–1328. https://doi.org/10.1134/S1027451017060210

S.W. Williams, F. Martina, A.C. Addison, J. Ding, G. Pardal, and P. Colegrove, Wire + arc additive manufacturing, Mater. Sci. Technol. (United Kingdom), 2016, 32, p 641–647. https://doi.org/10.1179/1743284715Y.0000000073

Y. Guo, H. Pan, L. Ren, and G. Quan, Microstructure and Mechanical Properties of Wire Arc Additively Manufactured AZ80M Magnesium Alloy, Mater. Lett., 2019, 247, p 4–6. https://doi.org/10.1016/j.matlet.2019.03.063

R. Tino, M. Leary, A. Yeo, E. Kyriakou, T. Kron, and M. Brandt, Additive Manufacturing in Radiation Oncology: A Review of Clinical Practice, Emerging Trends and Research Opportunities, Int. J. Extrem. Manuf., 2020, 2, p 012003.

F. Martina, J. Mehnen, S.W. Williams, P. Colegrove, and F. Wang, Investigation of the Benefits of Plasma Deposition for the Additive Layer Manufacture of Ti-6Al-4V, J. Mater. Process. Technol., 2012, 212, p 1377–1386. https://doi.org/10.1016/j.jmatprotec.2012.02.002

D. Ding, C. Shen, Z. Pan, D. Cuiuri, H. Li, N. Larkin, and S.V. Duin, Towards an Automated Robotic Arc-Welding-Based Additive Manufacturing System from CAD to Finished Part, CAD Comput. Aided Des., 2016, 73, p 66–75. https://doi.org/10.1016/j.cad.2015.12.003

D. Gu, M. Guo, H. Zhang, Y. Sun, R. Wang, and L. Zhang, Effects of Laser Scanning Strategies on Selective Laser Melting of Pure Tungsten, Int. J. Extrem. Manuf., 2020, 2, p 025001.

M. Balasubramanian, M.V. Choudary, A. Nagaraja, and K.O.C. Sai, Cold Metal Transfer Process—A Review, Mater. Today Proc., 2020 https://doi.org/10.1016/j.matpr.2020.05.225

B. Cong, J. Ding, and S. Williams, Effect of Arc Mode in Cold Metal Transfer Process on Porosity of Additively Manufactured Al-6.3%Cu Alloy, Int. J. Adv. Manuf. Technol., 2015, 76, p 1593–1606. https://doi.org/10.1007/s00170-014-6346-x

B. Cong, Z. Qi, B. Qi, H. Sun, G. Zhao, and J. Ding, A comparative study of additively manufactured thin wall and block structure with Al-6.3%Cu alloy using cold metal transfer process, Appl. Sci. (Switzerland), 2017 https://doi.org/10.3390/APP7030275

K. Liu, X. Chen, Q. Shen, Z. Pan, R.A. Singh, S. Jayalakshmi, and S. Konovalov, Microstructural Evolution and Mechanical Properties of Deep Cryogenic Treated Cu–Al–Si Alloy Fabricated by Cold Metal Transfer (CMT) Process, Mater. Charact., 2019 https://doi.org/10.1016/j.matchar.2019.110011

L. Kun, C. Xizhang, Z. Yupeng, P. Zengxi, R. Arvind Singh, S. Jayalakshmi, and K. Sergey, Location Dependence of Microstructure and Mechanical Properties of Cu-Al Alloy Fabricated by Dual Wire CMT, Mater. Res. Exp., 2019 https://doi.org/10.1088/2053-1591/ab583e

M. Zeren, Effect of Copper and Silicon Content on Mechanical Properties in Al-Cu-Si-Mg Alloys, J. Mater. Process. Technol., 2005, 169, p 292–298. https://doi.org/10.1016/j.jmatprotec.2005.03.009

X.M. Pan, C. Lin, J.E. Morral, and H.D. Brody, An Assessment of Thermodynamic Data for the Liquid Phase in the Al-Rich Corner of the Al-Cu-Si System and Its Application to the Solidification of a 319 Alloy, J. Phase Equilib. Diffus., 2005, 26, p 225–233. https://doi.org/10.1361/15477030523625

M. Weigl, F. Albert, and M. Schmidt, Enhancing the Ductility of Laser-Welded Copper-Aluminium Connections by Using Adapted Filler Material, Phys. Procedia, 2011, 12, p 335–341. https://doi.org/10.1016/j.phpro.2011.03.141

W. Yanhu, C. Xizhang, K. Sergey, S. Chuanchu, N.S. Arshad, and G. Namrata, In-Situ Wire-Feed Additive Manufacturing of Cu-Al Alloy by Addition of Silicon, Appl. Surf. Sci., 2019, 487, p 1366–1375. https://doi.org/10.1016/j.apsusc.2019.05.068

E. Aldalur, F. Veiga, A. Suárez, J. Bilbao, and A. Lamikiz, Analysis of the Wall Geometry with Different Strategies for High Deposition Wire Arc Additive Manufacturing of Mild Steel, Metals, 2020, 10, p 892. https://doi.org/10.3390/met10070892

Y. Ma, D. Cuiuri, N. Hoye, H. Li, and Z. Pan, Characterization of In-Situ Alloyed and Additively Manufactured Titanium Aluminides, Metall. Mater. Trans. B, 2014, 45, p 2299–2303. https://doi.org/10.1007/s11663-014-0144-6

R. Kainuma, N. Satoh, X.J. Liu, I. Ohnuma, and K. Ishida, Phase Equilibria and Heusler Phase Stability in the Cu-Rich Portion of the Cu-Al-Mn System, J. Alloys Comput., 1998, 266, p 191–200. https://doi.org/10.1016/S0925-8388(97)00425-8

D. Dudina, O. Lomovsky, K. Valeev, S. Tikhov, N. Boldyreva, A. Salanov, S. Cherepanova, V. Zaikovskii, A. Andreev, O. Lapina, and V. Sadykov, Phase Evolution During Early Stages of Mechanical Alloying of Cu-13 wt.% Al Powder Mixtures in a High-Energy Ball Mill, J. Alloys Comput., 2015, 629, p 343–350. https://doi.org/10.1016/j.jallcom.2014.12.120

J. Wang, Y. Iwahashi, Z. Horita, M. Furukawa, and T.G. Langdon, An Investigation of Microstructural Stability in an AlMg Alloy with Submicrometer Grain Size, Acta Mater., 1996, 44, p 2973–2982. https://doi.org/10.1016/1359-6454(95)00395-9

X.H. An, S.D. Wu, Z.G. Wang, and Z.F. Zhang, Significance of Stacking Fault Energy in Bulk Nanostructured Materials: Insights from Cu and Its Binary Alloys as Model Systems, Prog. Mater. Sci., 2019, 101, p 1–45. https://doi.org/10.1016/j.pmatsci.2018.11.001

H. Wang, R. Zhang, X. Hu, C.-A. Wang, and Y. Huang, Characterization of a Powder Metallurgy SiC/Cu–Al Composite, J. Mater. Process. Technol., 2008, 197, p 43–48. https://doi.org/10.1016/j.jmatprotec.2007.06.002

A.T. Adorno, and R.A. Silva, Ageing Behaviour in the Cu-10 wt.%Al and Cu-10 wt.%Al-4 wt.%Ag Alloys, J. Alloys Comput., 2009, 473, p 139–144. https://doi.org/10.1016/j.jallcom.2008.05.072

H.H. Kuo, W.H. Wang, and Y.F. Hsu, Microstructural Characterization of Precipitates in Cu-10 wt.%Al-08 wt.%Be Shape-Memory Alloy, Mater. Sci. Eng. A, 2006, 430, p 292–144. https://doi.org/10.1016/j.msea.2006.05.061

X. An, S. Qu, S.D. Wu, and Z.F. Zhang, Effects of Stacking Fault Energy on the Thermal Stability and Mechanical Properties of Nanostructured Cu–Al Alloys During Thermal Annealing, J. Mater. Res., 2011, 26, p 407–415. https://doi.org/10.1557/jmr.2010.39

M. Zeren, Effect of Copper and Silicon Content on Mechanical Properties in Al–Cu–Si–Mg Alloys, J. Mater. Process. Technol., 2005, 169, p 292–298. https://doi.org/10.1016/j.jmatprotec.2005.03.009

B.M. Gable, G.J. Shiflet, and E.A. Starke Jr., The Effect of Si Additions on Ω Precipitation in Al–Cu–Mg–(Ag) Alloys, Scr. Mater., 2004, 50, p 149–153. https://doi.org/10.1016/j.scriptamat.2003.09.004

L. Liu, J.H. Chen, S.B. Wang, C.H. Liu, S.S. Yang, and C.L. Wu, The Effect of Si on Precipitation in Al–Cu–Mg Alloy with a High Cu/Mg Ratio, Mater. Sci. Eng. A, 2014, 606, p 187–195. https://doi.org/10.1016/j.msea.2014.03.079

C.X. Ren, Q. Wang, J.P. Hou, Z.J. Zhang, H.J. Yang, and Z.F. Zhang, Exploring the Strength and Ductility Improvement of Cu–Al Alloys, Mater. Sci. Eng. A, 2020, 786, p 139441. https://doi.org/10.1016/j.msea.2020.139441

D. Han, Z.Y. Wang, Y. Yan, F. Shi, and X.W. Li, A Good Strength-Ductility Match in Cu-Mn Alloys with High Stacking Fault Energies: Determinant Effect of Short-Range Ordering, Scr. Mater., 2017, 133, p 59–64. https://doi.org/10.1016/j.scriptamat.2017.02.010

J.A. Yasi, L.G. Hector, and D.R. Trinkle, First-Principles Data for Solid-Solution Strengthening of Magnesium: From Geometry and Chemistry to Properties, Acta Mater., 2010, 58, p 5704–5713. https://doi.org/10.1016/j.actamat.2010.06.045

Acknowledgments

This work was sponsored by the National Natural Science Foundation of China under Grant No. 51975419 and Foreign Experts Bureau Project of China under Grant No. QN20200116001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Konovalov, S., Chen, X. et al. Research on Cu-6.6%Al-3.2%Si Alloy by Dual Wire Arc Additive Manufacturing. J. of Materi Eng and Perform 30, 1694–1702 (2021). https://doi.org/10.1007/s11665-021-05470-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05470-4