Abstract

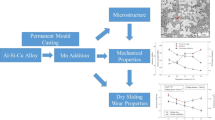

This work was carried out to evaluate the relationship between casting quality and wear properties of Al-12Si eutectic alloy with various Mg contents. Mg additions were selected as 0, 2, 3, and 4 wt.%. A permanent die tensile test mold, step-type mold, and RPT sand mold were used in the characterization of the properties of the castings. The bifilm index was measured for the determination of the casting quality. Mechanical properties such as hardness, UTS, YS, e (%), toughness, impact, and wear rate were investigated. All the results obtained in this study were evaluated via statistical analysis software. It was found that melt quality and bifilm index is the dominant factor that determines the mechanical properties. As Mg content was increased, the size of oxides was getting smaller and their number was increased. The highest wear properties were obtained with the highest Mg addition (4 wt.%) for ball-on-disk tests. According to the pin-on-disk test, in the lubricated conditions, there was no change in wear properties with Mg content. In the dry tests, as the bifilm index was increased, the friction coefficient was decreased due to the higher oxide content of the alloy.

Similar content being viewed by others

References

J.G. Kaufman and E.L. Rooy, Aluminum Alloy Castings: Properties, Processes, and Applications, ASM International, Cleveland, 2004

E. Sjölander and S. Seifeddine, The Heat Treatment of Al-Si-Cu-Mg Casting Alloys, J. Mater. Process. Technol., 2010, 210(10), p 1249–1259

K. Pratheesh et al., Effects of Sr and Pressure on Microstructure, Mechanical and Wear Properties of Near Eutectic Al-Si Piston Alloys, Int. J. Cast Met. Res., 2015, 28(5), p 301–309

M.M. Haque and A. Sharif, Study on Wear Properties of Aluminium–Silicon Piston Alloy, J. Mater. Process. Technol., 2001, 118(1), p 69–73

M. Harun, I.A. Talib, and A.R. Daud, Effect of Element Additions on Wear Property of Eutectic Aluminium-Silicon Alloys, Wear, 1996, 194(1), p 54–59

H. Murat Lus et al., Wear Properties of Squeeze Cast İn Situ Mg2Si-A380 Alloy, Int. J. Cast Met. Res., 2015, 28(1), p 59–64

T. Yasmin, A.A. Khalid, and M.M. Haque, Tribological (Wear) Properties of Aluminum–Silicon Eutectic Base Alloy Under Dry Sliding Condition, J. Mater. Process. Technol., 2004, 153–154, p 833–838

R.A. Al-Samarai, K.R.A. Haftirman, and Y. Al-Douri, The Tribological Behavior of Hypo-and Hyper-Eutectic Al-Si Alloys under Dry Sliding Conditions, International Journal of Mechanical and Production Engineering Research and Development (IJMPERD), 2013, 3(1), p 111–124

D.E. Lozano et al., Tribological Behaviour of Cast Hypereutectic Al-Si-Cu Alloy Subjected to Sliding Wear, Wear, 2009, 267(1), p 545–549

S. Hussain et al., Tribological Characteristics of Modified Hypo Eutectic Al-Si Alloy, in Key Engineering Materials. Trans Tech Publ. (2018)

Sunder Barangea, Sudhir Tiwarib, and Gautam Yadav, Tribological Investigations of Aluminum-Silicon (Al-Si) Alloys, International Journal for Scientific Research & Development, 2016, 4(08), p 398–401

R.A. Al-Samarai, A.K. Haftirman, and Y. Al-Douri, Effect of Load and Sliding Speed on Wear and Friction of Aluminum-Silicon Casting Alloy, Int. J. Sci. Res. Publ., 2012, 2(3), p 1–4

A. Sinha and Z. Farhat, Effect of Surface Porosity on Tribological Properties of Sintered Pure Al and Al 6061, Mater. Sci. Appl., 2015, 6(06), p 549

J. Campbell, Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design, Butterworth-Heinemann, Oxford, 2015

G.E. Bozchaloei et al., Effect of Oxide Bifilms on the Mechanical Properties of Cast Al-7Si-0.3 Mg Alloy and the Roll of Runner Height after Filter on Their Formation, Mater. Sci. Eng. A, 2012, 548, p 99–105

J. Campbell, An Overview of the Effects of Bifilms on the Structure and Properties of Cast Alloys, Metall. Mater. Trans. B, 2006, 37(6), p 857–863

D. Dispinar and J. Campbell, Use of Bifilm İndex as an Assessment of Liquid Metal Quality, Int. J. Cast Met. Res., 2006, 19(1), p 5–17

I.K. Duygun et al., Change in Sr Modification by Duration and Its Effect on Mechanical Properties of A360 and A413 Alloy, in Shape Casting. Springer. p. 353–361 (2019)

M. El-Sayed and W. Griffiths, Hydrogen, Bifilms and Mechanical Properties of Al Castings, Int. J. Cast Met. Res., 2014, 27(5), p 282–287

G. Gyarmati et al., The Effects of Rotary Degassing Treatments on the Melt Quality of an Al-Si Casting Alloy, Int. J. Metalcast., 2020, 2020, p 1–11

P. Ingle and B. Narkhede, Influence of Taguchi-Grey Relational Analysis of Gating System Design on Mechanical Properties of Casting. Archives of Foundry Engineering (2019)

H.S. Jang et al., Effects of Mg Content on Hydrogen Content and Melt Quality of Al-Mg Alloys, Metals, 2019, 9(11), p 1235

M.C. Mehta, D. Mandal, and S.K. Chaudhury, Microstructural Changes and Quality Improvement of Al7Si0.2Mg (356) Alloy by Die Vibration, Int. J. Metalcast., 2020, 2020, p 1–12

M. Tiryakioğlu and J. Campbell, Quality İndex for Aluminum Alloy Castings, Int. J. Metalcast., 2014, 8(3), p 39–42

T. Tunçay et al., Microstructure–Bifilm İnteraction and its Relation with Mechanical Properties in A356, Int. J. Cast Met. Res., 2017, 30(1), p 20–29

M. Uludağa et al., Mechanical Properties and Melt Quality Relationship of Sr-Modified Al-12Si Alloy, Arch. Foundry Eng., 2015, 15(4), p 134–140

C. Yüksel et al., Melt Cleaning Efficiency of Various Fluxes for A356 Alloy, in Shape Casting. Springer. p. 273–280 (2019)

E. Efzan et al., Effect of Alloying Element on Al-Si Alloys, in Advanced Materials Research. Trans Tech Publ. (2014)

Y. Liu and S. Kang, The Solidification Process of Al-Mg-Si Alloys, J. Mater. Sci., 1997, 32(6), p 1443–1447

A. Joenoes and J. Gruzleski, Magnesium Effects on the Microstructure of Unmodified and Modified Al-Si Alloys, Cast Met., 1991, 4(2), p 62–71

M. Tash et al., Effect of Metallurgical Parameters on the Hardness and Microstructural Characterization of As-Cast and Heat-Treated 356 and 319 Aluminum Alloys, Mater. Sci. Eng. A, 2007, 443(1), p 185–201

S. Kori, M. Prabhudev, and T. Chandrashekharaiah, Studies on the Microstructure and Mechanical Properties of A356 Alloy with Minor Additions of Copper and Magnesium, Trans. Indian Inst. Met., 2009, 62(4–5), p 353–356

M. Yıldırım and D. Özyürek, The Effects of Mg Amount on the Microstructure and Mechanical Properties of Al-Si-Mg Alloys, Mater. Des., 2013, 51, p 767–774

H.R. Ammar et al., Influences of Alloying Elements, Solution Treatment Time and Quenching Media on Quality İndices of 413-Type Al–Si Casting Alloys, Mater. Sci. Eng. A, 2008, 489(1), p 426–438

J. Parida et al., Effect of Heat Treatment on Wear Behaviour of Al-7wt%Si-X wt% Mg alloys. Materials Today: Proceedings (2020)

A. Hekmat-Ardakan et al., Wear Behaviour of Hypereutectic Al-Si-Cu-Mg Casting Alloys with Variable Mg Contents, Wear, 2010, 269(9), p 684–692

D.K. Dwivedi, Adhesive Wear Behaviour of Cast Aluminium–Silicon Alloys: Overview (1980-2015), Mater. Des., 2010, 31(5), p 2517–2531

B.P. Bai, E. Dwarakadasa, and S. Biswas, Subsurface DAMAGE in dry Wear of Al-Si Alloys, Wear, 1981, 71(3), p 381–384

J. Clarke and A.D. Sarkar, Wear Characteristics of as-Cast Binary Aluminium-Silicon Alloys, Wear, 1979, 54(1), p 7–16

Y. Sun and H. Ahlatci, Mechanical and Wear Behaviors of Al-12Si-XMg Composites Reinforced with İn Situ Mg2Si Particles, Mater. Des., 2011, 32(5), p 2983–2987

V. Abouei, S.G. Shabestari, and H. Saghafian, Dry Sliding Wear Behaviour of Hypereutectic Al-Si Piston Alloys Containing İron-Rich İntermetallics, Mater. Charact., 2010, 61(11), p 1089–1096

M.S. Kaiser, Solution Treatment Effect on Tensile, Impact and Fracture Behaviour of Trace Zr Added Al-12Si-1Mg-1Cu Piston Alloy, J. Inst. Eng. (India) Ser. D, 2018, 99(1), p 109–114

M. Gupta and S. Ling, Microstructure and Mechanical Properties of Hypo/hyper-Eutectic Al-Si Alloys Synthesized USİNG a near-Net Shape Forming Technique, J. Alloys Compd., 1999, 287(1–2), p 284–294

L. Pedersen and L. Arnberg, The Effect of Solution Heat Treatment and Quenching Rates on Mechanical Properties and Microstructures in AlSiMg Foundry Alloys, Metall. Mater. Trans. A, 2001, 32(3), p 525–532

R.X. Li et al., Age-Hardening Behavior of Cast Al-Si Base Alloy, Mater. Lett., 2004, 58(15), p 2096–2101

D. Apelian, S. Shivkumar, and G. Sigworth, Fundamental Aspects of Heat Treatment of Cast Al-Si-Mg Alloys, AFS Trans., 1989, 97, p 727–742

V. Shivaprasad, P.S. Dixit, and H. Nalatore, Changes in Structural Features of Al-12Si-3Cu Alloy Due to Age Hardening (2017)

G.-S. Ham et al., Effect of Heat Treatment on Tensile and Fatigue Deformation Behavior of Extruded Al-12 wt% Si Alloy, Met. Mater. Int., 2017, 23(1), p 35–42

R. Chen et al., Correlation of Solidification Microstructure Refining Scale, Mg Composition and Heat Treatment Conditions with Mechanical Properties in Al-7Si-Mg Cast Aluminum Alloys, Mater. Sci. Eng. A, 2017, 685, p 391–402

J.-H. Peng et al., Effect of Heat Treatment on Microstructure and Tensile Properties of A356 Alloys, Trans. Nonferr. Met. Soc. China, 2011, 21(9), p 1950–1956

R. Sharma, Anesh, and D.K. Dwivedi, Influence of Silicon (wt.%) and Heat Treatment on Abrasive Wear Behaviour of cast Al-Si-Mg Alloys, Mater. Sci. Eng. A, 2005, 408(1), p 274–280

D. Dispinar and J. Campbell, Determining Aluminium Melt Quality, Aluminium in India, 2005, 4(4), p 3–11

D. Dispinar and J. Campbell, Reduced Pressure Test (RPT) for Bifilm Assessment, in Shape Casting: 5th International Symposium 2014. Springer (2014)

M. Uludağ, L. Gemi, and D. Dispinar, Statistical Analysis on the Effect of the Solidification Rate and Quenching Mediums on Mechanical Properties in ETIAL 221 Alloy, in Uludağ University Journal of The Faculty of Engineering (2020)

H. Dvorak and E. Schwegtier, Statistical Distribution of Flaw Sizes, Int. J. Fract.Mech., 1972, 8(1), p 110–111

A.P. Hekimoğlu, M. Çalış, and G. Ayata, Effect of Strontium and Magnesium Additions on the Microstructure and Mechanical Properties of Al-12Si Alloys, Met. Mater. Int., 2019, 25(6), p 1488–1499

T. Gao et al., Phase Evolution of β-Al 5 FeSi During Recycling of Al-Si-Fe Alloys by Mg Melt, Int. J. Metalcast., 2019, 13(2), p 473–478

Y.C. Lin et al., Effects of Solution Treatment on Microstructures and Micro-hardness of a Sr-Modified Al-Si-Mg Alloy, Mater. Sci. Eng., A, 2018, 725, p 530–540

W. Kurz and D. Fisher, Fundamentals of Solidification; 1992. Trans Tech Publications (1989)

M. Uludağ, R. Çetin, and D. Dispinar, Freezing Range, Melt Quality, and Hot Tearing in Al-Si Alloys, Metall. Mater. Trans. A, 2018, 49(5), p 1948–1961

M. Uludağ et al., On the İnterpretation of Melt Quality Assessment of A356 Aluminum Alloy by the Reduced Pressure Test: The Bifilm İndex and its Physical Meaning, Int. J. Metalcast., 2018, 12(4), p 853–860

M. Uludağ et al., Characterization of the Effect of Melt Treatments on Melt Quality in Al-7wt% Si-Mg Alloys, Metals, 2017, 7(5), p 157

J. Campbell, Discussion of “Investigation of Oxide Bifilms in Investment Cast Superalloy IN100 Parts I, and II”, Metall. Mater. Trans. A, 2017, 48(10), p 5151–5153

M. El-Sayed, H. Hassanin, and K. Essa, Bifilm Defects and Porosity in Al Cast Alloys, Int. J. Adv. Manuf. Technol., 2016, 86(5–8), p 1173–1179

M. Uludağ et al., Change in Porosity of A356 by Holding Time and its Effect on Mechanical Properties, J. Mater. Eng. Perform., 2018, 27(10), p 5141–5151

M. Uludağ et al., The Effect of Holding Time and Solidification Rate on Porosity of A356, Am. J. Eng. Res, 2016, 5(12), p 271–275

M. Uludağ et al., Relationship Between Machinability, Microstructure, Mechanical Properties of Al-7Si Alloy, J. Test. Eval., 2018, 46(6), p 2592–2603

J.T. Staley, Jr., M. Tiryakioğlu, and J. Campbell, The Effect of İncreased HIP Temperatures on Bifilms and Tensile Properties of A206-T71 Aluminum Castings, Mater. Sci. Eng. A, 2007, 460, p 324–334

X. Cao and J. Campbell, Oxide İnclusion Defects in Al-Si-Mg Cast Alloys, Can. Metall. Q., 2005, 44(4), p 435–448

S.M. Miresmaeili et al., Precipitation of Sr-Rich İntermetallic Particles and Their İnfluence on Pore Formation in Sr-Modified A356 Alloy, Metall. Mater. Trans. A, 2005, 36(9), p 2341–2349

M. Divandari and J. Campbell, Mechanisms of Bubble Damage in Castings (2001)

B.N. Sutrisno, and H.C.K. Agustin, Effects of Bifilm on the Response of Artificial Aging of Aluminium Alloy ADC12, in AIP Conference Proceedings. AIP Publishing LLC (2019)

P. Davami, S. Kim, and M. Tiryakioğlu, The Effect of Melt Quality and Filtering on the Weibull Distributions of Tensile Properties in Al-7% Si-Mg Alloy Castings, Mater. Sci. Eng. A, 2013, 579, p 64–70

M.A. El-Sayed et al., Effect of Holding Time Before Solidification on Double-Oxide Film Defects and Mechanical Properties of Aluminum Alloys, Metall. Mater. Trans. B, 2011, 42(6), p 1104–1109

D. Lee, J. Park, and S.W. Nam, Enhancement of Mechanical Properties of Al-Mg-Si Alloys by Means of Manganese Dispersoids, Mater. Sci. Technol., 1999, 15(4), p 450–455

Y. Liu et al., Effect of Mg on Microstructure and Mechanical Properties of Al-Mg Alloys Produced by High Pressure Torsion, Scripta Mater., 2019, 159, p 137–141

A.S. Anasyida, A.R. Daud, and M.J. Ghazali, Dry Sliding Wear Behaviour of Al-12Si-4Mg Alloy with Cerium Addition, Mater. Des., 2010, 31(1), p 365–374

B.K. Yen and T. Ishihara, Effect of Humidity on Friction and Wear of Al-Si Eutectic Alloy and Al-Si Alloy-Graphite Composites, Wear, 1996, 198(1), p 169–175

P. Davami et al., Effect of Oxide Films, İnclusions and Fe on Reproducibility of Tensile Properties in Cast Al-Si-Mg Alloys: Statistical and İmage Analysis, Mater. Sci. Eng. A, 2012, 558, p 134–143

M. Tiryakioğlu, Fracture Toughness Potential of Cast Al-7% Si-Mg Alloys, Mater. Sci. Eng. A, 2008, 497(1–2), p 512–514

G. Timelli, G. Camicia, and S. Ferraro, Effect of Grain Refinement and Cooling Rate on the Microstructure and Mechanical Properties of Secondary Al-Si-Cu Alloys, J. Mater. Eng. Perform., 2014, 23(2), p 611–621

M.A. Nozari et al., Effect of Be Modification on the Oxide Bifilms and Tensile Strength Reliability of Al-Si-Mg Alloys Containing Excess Fe, Metall. Mater. Trans. B, 2018, 49(3), p 1236–1245

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Uludağ, M. A Statistical Assessment of Casting Quality–Tribological Properties of Eutectic Al-12Si Alloy: Effect of Mg. J. of Materi Eng and Perform 29, 7526–7543 (2020). https://doi.org/10.1007/s11665-020-05225-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05225-7