Abstract

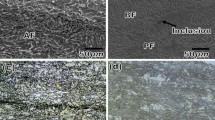

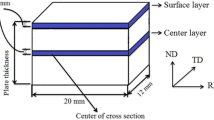

This research work focuses on the investigation of the correlation between hydrogen cathodic charging conditions and toughness properties of a welded X65 pipeline steels. The experimental technique which was applied to determine the characteristic parameters associated with toughness was the crack tip open displacement after hydrogen cathodic charging process. The hydrogen cathodic charging process was carried out in an electrolytic cell with applied current densities of 10, 20, 30 mA/cm2 and hydrogen cathodic charging duration 48 h. Through this study, interesting results were provided concerning the diffusion depth and the diffusion coefficient of atomic hydrogen as far as toughness properties. The maximum diffusion depth value is assigned for each current density field in the region of heat-affected zone and the minimum in the area of fusion zone. In addition, the highest diffusion coefficients are attributed to heat-affected zone and the lowest to fusion zone, for all applied current densities. Finally, the fusion zone is considered to be more prone to the occurrence of embrittlement phenomena compared to base metal. The rate of toughness parameters drop is higher for current densities between 0-10 and 20-30 mA/cm2, where the cathodic current promotes the electrochemical reduction in hydrogen cations to atomic hydrogen.

Similar content being viewed by others

References

R. Wang, Effects of Hydrogen on the Fracture Toughness of a X70 Pipeline Steel, Corros. Sci., 2009, 51, p 2803–2810

R. Thodla, M.T. Piza Paes, and B. Gerst, Hydrogen Assisted Cracking of AISI, 4137 M Steel in O&G Environments, Int. J. Hydrogen Energy, 2015, 40, p 17051–17064

C. Park, N. Kang, and S. Liu, Effect of Grain Size on the Resistance to Hydrogen Embrittlement of API, 2 W Grade 60 Steels Using In Situ Slow-Strain-raTe Testing, Corros. Sci., 2017, 128, p 33–41

S.P. Lynch, The Minerals, “Hydrogen Effects in Materials”, Met. Mater. Soc., 2003, 26, p 153–156

X. Ren, W. Chu, J. Li, Y. Su, and L. Qiao, The Effects of Inclusions and Second Phase Particles on Hydrogen-Induced Blistering in Iron, Mater. Chem. Phys., 2008, 107, p 231–235

M.C. Tiegel, M.L. Martin, A.K. Lehmberg, M. Deutges, C. Borchers, and R. Kirchheim, Crack and Blister Initiation and Growth in Purified Iron Due to Hydrogen Loading, Acta Mater., 2016, 115, p 24–34

D. Perez Escobar, C. Minambres, L. Duprez, K. Verbeken, and M. Verhaege, Internal and Surface Damage of Multiphase Steels and Pure Iron after Electrochemical Hydrogen Charging, Corros. Sci., 2011, 53, p 3166–3176

X.C. Ren, Q.J. Zhou, G.B. Shan, W.Y. Chu, J.X. Li, Y.J. Su, and L.J. Qiao, A Nucleation Mechanism of Hydrogen bliSter in Metals, Metall. Mater. Trans., 2008, 39, p 87–97

M. Elboujdaini, R. Winston Revie (ed.), Uhlig’s Corrosion Handbook, Hydrogen-Induced Cracking and Sulfide Stress Cracking, Wiley, Hoboken (2001)

E. De Bruycker, S. De Vroey, S. Huysmans, and J. Stubbe, Phenomenology of Hydrogen Flaking in Nuclear Reactor Pressure Vessels, Mater. Test., 2014, 56, p 439–444

K.D. Chang, J.L. Gu, H.S. Fang, Z.G. Yang, B.Z. Bai, and W.Z. Zhang, Effects of Heat-treatment Process of a Novel Bainite/Martensite Dual-phase High Strength Steel on Its Susceptibility to Hydrogen Embrittlement, ISIJ Int., 2001, 41, p 1397–1401

M. Cabrini, S. Lorenzi, S. Pelegrini, and T. Pastore, Environmentally Assisted Cracking and Hydrogen Diffusion in Traditional and High-Strength Pipeline Steels, Corros. Rev., 2015, 3, p 529–545

M.B. Djukic, V. SijackiZeravcic, G.M. Bakic, A. Sedmak, and B. Rajicic, Hydrogen Damage of Steels: A Case Study and Hydrogen Embrittlement Model, Eng. Fail. Anal., 2015, https://doi.org/10.1016/j.engfailanal.2015.05.017

M.B. Djukic, G.M. Bakic, V. Sijacki Zeravcic, A. Sedmak, and B. Rajicic, The Synergistic Action and Interplay of Hydrogen Embrittlement Mechanisms in Steels and Iron: Localized Plasticity and Decohesion, Eng. Fract. Mech., 2019, https://doi.org/10.1016/j.engfracmech.2019.106528

F. Huang, J. Liu, Z.J. Deng, J.H. Cheng, Z.H. Lu, and X.G. Li, Effect of Microstructure and Inclusions on Hydrogen Induced Cracking Susceptibility and Hydrogen Trapping Efficiency of X120 Pipeline Steel, Mater. Sci. Eng., 2010, 527, p 6997–7001

H.B. Xue and Y.F. Cheng, Hydrogen Permeation and Electrochemical Corrosion Behavior of the X80 Pipeline Steel Weld, J. Mater. Eng. Perform., 2012, 22, p 170–175

W. Zhao, Y. Wang, T. Zhang, and Y. Wang, Study on the Mechanism of High-Cycle Corrosion Fatigue Crack Initiation in X80 Steel, Corros. Sci., 2012, 57, p 99–103

R. Pamnani, T. Jayakumar, M. Vasudevan, and T. Sakthivel, Investigations on the Impact Toughness of HSLA Steel Arc Welded Joints, J. Manuf. Process., 2016, 21, p 75–86

R. Pamnani, V. Karthik, T. Jayakumar, M. Vasudevan, and T. Sakthivel, Evaluation of Mechanical Properties across Micro Alloyed HSLA Steel Weld Joints Using Automated Ball Indentation, Mater. Sci. Eng., 2016, 651, p 214–223

J.J.M. Jebaraj, D.J. Morrison, and I.I. Suni, Hydrogen Diffusion Coefficients through Inconel 718 in Different Metallurgical conditions, Corros. Sci., 2014, 80, p 517–522

T. Boiadjieva, L. Mirkova, H. Kronberger, T. Steck, and M. Monev, Hydrogen Permeation Through Steel Electroplated with Zn or Zn-Cr coati-ngs, Electrochim. Acta, 2013, 114, p 790–798

Y. Kyo, A.P. Yadav, A. Nishikata, T. Tsuru, T. Zhang et al., Comparison of Hydrogen Embrittlement Susceptibility of Three Cathodic Protected Subsea Pipeline Steels from a Point of View of Hydrogen Permeation, Corros. Sci., 2018, 131, p 104–115

K. Xu, “Evaluation of API 5L X80 Steel in High Pressure Hydrogen Gas”, ASTM G1 Hydrogen Embrittlement Workshop, 2005

R.J. Walter and W.T. Chandler, “Cyclic-Load Crack Growth in ASME SA-105 Grade II Steel in High-Pressure Hydrogen at Ambient Temperature”, Effect of Hydrogen on Behavior of Materials Moran”, WY, 1976, p 273–286

H.J. Cialone and J.H. Holbrook, Effects of Gaseous Hydrogen on Fatigue Crack Growth in Pipeline Steel, Metall. Trans. A, 1985, 16(1), p 115–122

Q. Robert, L. Amaro, A. NehaRustagia, O. Kip, B. Findley, S. Elizabeth, A. Drexler, J. Andrew, and A. Slifka, Modeling the Fatigue Crack Growth of X100 Pipeline Steel in Gaseous Hydrogen, Int. J. Fatigue, 2014, 59, p 262–271

L.W. Tsay, M.C. Young, and C. Chen, Fatigue Crack Growth Behavior of Laser-Processed 304 Stainless Steel in Air and Gaseous Hydrogen, Corros. Sci., 2003, 45, p 1985–1997

M. Cabrini, S. Lorenzi, T. Pastore, and D.P. Bucella, Hydrogen Diffusion in Low Alloy Steels under Cyclic Loading, Corros. Rev., 2019, 37, p 459–467

M. Cabrini, E. Sinigaglia, C. Spinelli, M. Tarenzi, C. Testa, and F.M. Bolzoni, Hydrogen Embrittlement Evaluation of Micro Alloyed Steels by Means of J Integral Curve, Materials, 2019, 12, p 161–183

M. Masoumi, C.C. Silva, and H.F. Gomes de Abreu, Effect of Crystallographic Orientations on the Hydrogen-Induced Cracking Resistance Improvement of API, 5L X70 Pipeline Steel under Various Thermomechanical Processing, Corros. Sci., 2016, 111, p 121–131

Y. Zhao, Y. Seok, C. Choi, and Y.H. Lee, The Role of Hydrogen in Hardening/Softening Steel: Influence of the Charging Process, Scr. Mater., 2015, 107, p 140–156

D. Zang, P. Maroevic, and R.B. McLellan, Hydrogen-Induced Vacancies on Metal Surfaces, J. Phys. Chem. Solids, 1999, 60, p 1649–1654

R.B. McLellan and Z.R. Xu, Hydrogen-Induced Vacancies in the Iron Lattice, Scr. Mater., 1997, 36, p 1201–1205

M. Åsa and S. Rolf, Hydrogen Depth Profile in Phosphorus-Doped, Oxygen-Free Copper after Cathodic Charging, J. Mater. Sci., 2012, 47, p 6768–6776

C.N. Panagopoulos, A.S. El-Amoush, and K.G. Georgarakis, The Effect of Hydrogen Charging on the Mechanical Behaviour of α-Brass, J. Alloys Compd., 2005, 392, p 159–164

B.E. Wilde, C.D. Kim, and E.H. Phelphs, Some Observations on the Role of Inclusions in the Hydrogen Induced Blister Cracking of Linepipe Steels in Sulfide Environments, Corrosion, 2000, 36, p 625–632

E. Fallahmohammadi, F. Bolzoni, G. Fumagalli, G. Re, G. Benassi, and L. Lazzari, Hydrogen Diffusion into Three Metallurgical Microstructures of a C-Mn X65 and Low Alloy F22 Sour Service Steel Pipelines, Int. J.Hydrogen Energy, 2014, 39, p 13300–13313

E. Shekari, M.R. Shishesaz, G.H. Rashed, M. Farzam, and E. Khayer, Failure Investigation of Hydrogen Blistering on Low Strength Carbon Steel, Iran. J. Oil Gas Sci. Technol., 2013, 2, p 65–76

T.Y. Jin, Z.Y. Liu, and Y.F. Cheng, Effect of Non-metallic Inclusions on Hydrogen—Induced Cracking of API5L X100 Steel, Int. J.Hydrogen Energy, 2010, 35, p 8014–8021

G.N. Haidemenopoulos, H. Koumoutsi, K. Polychronopoulou, P. Papageorgiou, I. Atlanis, P. Dimitriadis, and M. Stiakakis, Investigation of Stress Oriented Hydrogen Induced Cracking (SOHIC) in an Amine Absorber Column of an Oil Refinery, Metals, 2018, 8, p 663–680

Y. Song, M. Chai, and G. Cheng, Experimental Investigation of the Effect of Hydrogen on Fracture Toughness of 2.25 Cr-1 Mo-0.25 V Steel and Welds after Annealing, Materials, 2018, 11, p 499–513

L.B. Peral, A. Zafra, C. Rodriguez, and J. Belzunce, Evaluation of Strength and Fracture Toughness of Ferritic High Strength Steels under Hydrogen Environments, Proc. Struct. Integr., 2017, 5, p 1275–1282

E.V. Chatzidouros, V.I. Papazoglou, and D.I. Pantelis, Hydrogen Effect on a Low Carbon Ferritic–Bainitic Pipeline Steel, Int. J. Hydrogen Energy, 2014, 39, p 18498–18505

E.V. Chatzidouros, A. Traidia, R.S. Devarapalli, D.I. Pantelis, and T.A. Steriotis, Effect of Hydrogen on Fracture Toughness Properties of a Pipeline Steel under Simulated Sour Service Conditions, Int. J. Hydrogen Energy, 2018, 43, p 5747–5759

E.G. Astafurova, G.G. Maier, E.V. Melnikov, V.A. Moskvina, V.F. Vojtsik, G.N. Zakharov, A.I. Smirnov, and V.A. Bataev, Effect of Hydrogen Charging on Mechanical Twinning, Strain Hardening, and Fracture of <111> and <144> Hadfield Steel Single Crystals, Phys. Mesomech., 2018, 21, p 263–275

A. Laureys, R. Petrov, E. Van den Eeckhout, and K. Verbeken, Effect of Deformation and Charging Conditions on Crack and Blister Formation during Electrochemical Charging, Acta Mater., 2017, 127, p 125–138

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kyriakopoulou, H.P., Belntekos, I.D., Tazedakis, A.S. et al. Investigation of the Correlation between Hydrogen Cathodic Charging Conditions and Toughness Properties of Longitudinal Submerged Arc Welded X65 Pipeline Steels. J. of Materi Eng and Perform 29, 3205–3219 (2020). https://doi.org/10.1007/s11665-020-04864-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04864-0