Abstract

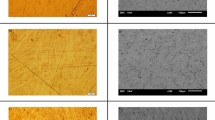

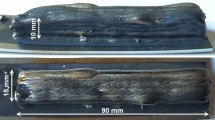

Sintered NdFeB permanent magnets and steel were soldered successfully using Zn-Sn alloy. The effects of Sn content on the microstructure and mechanical properties of soldered joints were investigated. The results showed that the typical interfacial microstructure represented NdFeB/NdFe5.5Zn(B) + ξ-FeZn13/Zn + β-Sn/ξ-FeZn13 + δ-FeZn10 + Γ-Fe3Zn10/steel. With the addition of Sn, the thickness of the NdFe5.5Zn(B) phase increased, while more β-Sn was observed in the soldering seam. The maximum shear strength reached 45.3 MPa with a Sn proportion of 6 wt.%, and excessive growth of the NdFe5.5Zn(B) phase in the joints deteriorated the mechanical properties. The fracture morphology exhibited a ductile-to-brittle transition with the occurrence of interfacial fractures due to thick intermetallic compounds.

Similar content being viewed by others

References

M. Sagawa, S. Fujimura, N. Togawa, H. Yamamoto, and Y. Marsuura, New Material for Permanent Magnets on a Base of Nd and Fe, J. Appl. Phys., 1984, 55(6), p 2083–2087

Y. Matsuura, Recent Development of Nd-Fe-B Sintered Magnets and Their Applications, J. Magn. Magn. Mater., 2006, 303(2), p 344–347

O. Gutfleisch, M.A. Willard, E. Brück, C.H. Chen, S.G. Sankar, and J.P. Liu, Magnetic Materials and Devices for the 21st Century: Stronger, Lighter, and More Energy Efficient, Adv. Mater., 2011, 23(7), p 821–842

Y.J. Li, Q. Dai, C.Y. Deng, R.X. Sun, J. Zheng, Z. Chen, Y. Sun, H. Wang, Z.D. Yuan, C. Fang, and Z.G. Deng, Field Homogeneity Improvement of Maglev NdFeB Magnetic Rails from Joints, SpringerPlus, 2016, 5(1), p 372–382

H. Kim, C. Koh, D. Kim, and G. Kang, Application of Polar Anisotropic Sintered NdFeB Ring-Type Permanent Magnet to Brush-Less DC Motor, IEEE Trans. Magn., 2006, 43, p 2522–2524

S. Chatterjee, S. Koley, R.B. Sarkar, N. Behera, M. Manna, S. Mukherjee, and S. Kundu, Design and Development of Galvannealed Dual-Phase Steel: Microstructure, Mechanical Properties and Weldability, J. Mater. Eng. Perform., 2019, 28(1), p 231–241

H. Yang, Y. Du, and Z. Sun, The Analysis of Adhesion Failure Between Ni-Coating and Sintered NdFeB Substrate, J. Phys. Conf. Ser., 2011, 266, p 1–5

P. Zhang, G. Xu, J. Liu, X. Yi, Y. Wu, and J. Chen, Effect of Pretreating Technologies on the Adhesive Strength and Anticorrosion Property of Zn Coated NdFeB Specimens, Appl. Surf. Sci., 2016, 363, p 499–506

P. Zhang, J. Liu, G. Xu, X. Yi, J. Chen, and Y. Wu, Anticorrosive Property Al Coatings on Sintered NdFeB Substrates Via Plasma Assisted Physical Vapor Deposition Method, Surf. Coat. Technol., 2015, 282, p 86–93

B.H. Chang, S.J. Bai, D. Du, H. Zhang, and Y. Zhou, Studies on the Micro-Laser Spot Welding of an NdFeB Permanent Magnet with a Low Carbon Steel, J. Mater. Process. Tech., 2010, 210(6), p 885–891

B.H. Chang, D. Du, C.H. Yi, B. Xing, and Y.H. Li, Influences of Laser Spot Welding on Magnetic Property of a Sintered NdFeB Magnet, Metals, 2016, 202(6), p 1–9

K. Suganuma, S.-J. Kim, and K.-S. Kim, High-Temperature Lead-Free Solders: Properties and Possibilities, JOM, 2009, 61, p 64–71

G. Zeng, S. McDonald, and K. Nogita, Development of High-Temperature Solders: Review, Microelectron. Reliab., 2012, 52, p 1306–1322

F.P. McCluskey, M. Dash, Z. Wang, and D. Huff, Reliability of High Temperature Solder Alternatives, Microelectron. Reliab., 2006, 46, p 1910–1914

Y.-A. Shen, C.-M. Lin, J. Li, R. Gao, and H. Nishikawa, Suppressed Growth of (Fe, Cr, Co, Ni, Cu) Sn2 Intermetallic Compound at Interface Between Sn-3.0 Ag-0.5 Cu Solder and FeCoNiCrCu0.5 Substrate During Solid-State Aging, Sci. Rep., 2019, 9, p 1–5

M. Xiong and L. Zhang, Interface Reaction and Intermetallic Compound Growth Behavior of Sn-Ag-Cu Lead-Free Solder Joints on Different Substrates in Electronic Packaging, J. Mater. Sci., 2019, 54, p 1741–1768

A. Debski, W. Gasior, Z. Moser, and R. Major, Enthalpy of Formation of Intermetallic Phases from the Au-Sn System, J. Alloys Compd., 2010, 491, p 173–177

W. Tang, A. He, Q. Liu, and D.G. Ivey, Fabrication and Microstructures of Sequentially Electroplated Au-rich, Eutectic Au/Sn Alloy Solder, J. Mater. Sci.: Mater. Electron., 2008, 19, p 1176–1183

T. Shimizu, H. Ishikawa, I. Ohnuma, and K. Ishida, Zn-Al-Mg-Ga Alloys as Pb-Free Solder for Die-Attaching Use, J. Electron. Mater., 1999, 28, p 1172–1175

J.-E. Lee, K.-S. Kim, K. Suganuma, M. Inoue, and G. Izuta, Thermal Properties and Phase Stability of Zn-Sn and Zn-In Alloys as High Temperature Lead-Free Solder, Mater. Trans., 2007, 48, p 584–593

T. Takahashi, S. Komatsu, H. Nishikawa, and T. Takemoto, Improvement of High-temperature Performance of Zn-Sn Solder Joint, J. Electron. Mater., 2010, 39, p 1241–1247

S. Kim, K.-S. Kim, and K. Suganuma, Interfacial Reaction and die Attach Properties of Zn-Sn High-Temperature Solders, J. Electron. Mater., 2009, 38, p 266–272

Y. Hu, I.P. Jones, M. Aindow, and I.R. Harris, Zn Diffusion Induced Precipitation Along Grain Boundaries in Zn-Coated NdFeB Magnets, J. Magn. Magn. Mater., 2003, 261(1), p 13–20

A.R. Marder, The Metallurgy of Zinc-Coated Steel, Prog. Mater. Sci., 2000, 45, p 191–271

N.L. Okamoto, D. Kashioka, M. Inomoto, H. Inui, H. Takebayashi, and S. Yamaguchi, Compression Deformability of Γ and ζ Fe-Zn Intermetallics to Mitigate Detachment of Brittle Intermetallic Coating of Galvannealed Steels, Scr. Mater., 2013, 69(4), p 307–310

X. Yang, W. Hu, X. Yan, and Y. Lei, Microstructure and Solderability of Zn-6Al-xSn Solders, J. Electron. Mater., 2015, 44(4), p 1128–1133

T. Zhang, X. Yang, K. Miao, D. Li, S. Chen, X. Cui, M. Huang, G. Fan, and L. Geng, Microstructure Evolution and Brazing Mechanism of Ti5Si3/Ti3Al composite and Ni-Based Superalloy Joints Using Ti-Zr-Cu-Ni Filler Alloy, Mater. Sci. Eng., A, 2018, 713, p 28–34

X.Q. Si, H.Y. Zhao, J. Cao, X.G. Song, D.Y. Tang, and J.C. Feng, Brazing High Nb Containing TiAl Alloy Using Ti-28Ni Eutectic Brazing Alloy: Interfacial Microstructure and Joining Properties, Mater. Sci. Eng., A, 2015, 636, p 522–528

G. Feng, Z. Li, Z. Zhou, Y. Yang, D.P. Sekulic, and M.R. Zachariah, Microstructure and Mechanical Properties of Cf/Al-TiAl Laser-Assisted Brazed Joint, J. Mater. Process. Tech., 2018, 255, p 195–203

V. Raghavan, Fe-Zn, J. Phase Equilibria, 2003, 24, p 544–545

Acknowledgments

This work was supported by the Development of Science and Technology of Jilin Province (Grant No. 20180520005JH).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Luo, C., Qiu, X., Xu, Y. et al. Microstructure and Interfacial Evolution of Sintered NdFeB Permanent Magnet/Steel Joint Soldered with Zn-Sn Alloy. J. of Materi Eng and Perform 29, 3373–3382 (2020). https://doi.org/10.1007/s11665-020-04854-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04854-2