Abstract

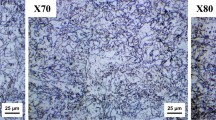

API X60 steel used for reeled pipeline was subjected to different amounts of cyclic plastic deformation (CPD) by multiple tension–compression tests in order to study the deformation behavior and microstructural evolution during each stage of reel-lay installation process. It was found that the yield strength was significantly reduced by about 110 MPa during the first CPD cycle due to the Bauschinger effect. However, the yield strength was little affected by the subsequent CPD cycles, and the yield strength difference between tension and compression tended to reach a steady-state value of 23 MPa after multiple CPD cycles. With the increase in CPD cycles, the proportion of low-angle grain boundaries declined from 50.9 to 35.7%, and the CPD contributed to the formation of immovable dislocation walls and cells due to the dislocation rearrangement, causing the stable yield strength. The CPD process with strain level of 3% had no prominent effect on the tensile strength and elongation, because the change in microstructures was not enough to alter the work hardening completely after multiple CPD cycles.

Similar content being viewed by others

References

L. Penati, M. Ducceschi, A. Favi, and D. Rossin, in Installation Challenges for Ultra-Deep Waters. Proceedings of Offshore Mediterranean Conference and Exhibition, Offshore Mediterranean Conference, Ravenna, Italy, 2015, Paper No. 441

L.N. Li, W.J. Zhong, Y. Jiang, N.Q. He, and C.G. Sun, in Development of a New Installation System for Deepwater Riser and Subsea Structure. Proceedings of 26th International Ocean and Polar Engineering Conference, Rhodes, Greece, 2016, Paper No. 505

J.X. Yu, M.N. Wu, Z.Z. Sun, and J.H. Duan, Research Progress of Buckling Propagation Experiment of Deep-Water Pipelines, Trans. Tianjin Univ., 2016, 22(4), p 285–293

S. Kyriakides and E. Corona, Mechanics of Offshore Pipelines: Buckling and Collapse, Vol 1, Elsevier Press, Oxford, 2007

B.Y. Guo, S.H. Song, J. Chacko, and A. Ghalambor, Offshore Pipelines, Elsevier Press, Oxford, 2005

A. Meissner, M. Erdelen-Peppler, and T. Schmidt, n Impact of Reel-Laying on Mechanical Pipeline Properties Investigated by Full- and Small-Scale Reeling Simulations. Proceedings of 19th International Offshore and Polar Engineering Conference, Osaka, Japan, 2009, Paper No. 390

T. Sriskandarajah, D. Mackay, V. Rao, D. Zhou, P. Ragupathy, S. Kashani, and B. Power, in Technical Challenges of Design for Installation of Reel-Layed Pipe-In-Pipe System for a Deepwater Application. Proceedings of 27th International Ocean and Polar Engineering Conference, San Francisco, USA, 2017, Paper No. 121

S. Kyriakides, Effects of Reeling on Pipe Structural Performance-Part I: Experiments, J. Offshore Mech. Arct. Eng., 2017, 139(5), p 051706

I. Marines-Garcia, J.A. Aldana-Díaz, P.P. Darcis, and H.M. Quintanilla, in Seamless Linepipe Response Under Small and Full Scale Reeling Simulation. Proceedings of 35th International Conference on Ocean, Offshore and Arctic Engineering, Busan, South Korea, 2016, Paper No. 54031

M.A.N. Beltrão and F.L. Bastian, Fractographic Analysis of Weld Metal and HAZ Regions of API, X-80 Steel Subjected to Simulation of the Reel-Lay Method, J. Mater. Eng. Perform., 2014, 23(10), p 3523–3533

T.A. Netto, A. Botto, and M.I. Lourenço, Fatigue Performance of Pre-strained Pipes with Girth Weld Defects: Local Deformation Mechanisms under Bending, Int. J. Fatigue, 2008, 30(6), p 1080–1091

S. Lin, D.P. Wang, C.N. Li, X.G. Liu, X.J. Di, and Y.B. Jiang, Effect of Cyclic Plastic Deformation on Microstructure and Mechanical Properties of Weld Metals used for Reel-lay Pipeline Steels, Mater. Sci. Eng., A, 2018, 737, p 77–84

DNV Offshore Standard, DNV OS F101: Submarine Pipeline Systems, Det Norske Veritas (2013)

E. Anelli, M. Tivelli, A. Izquierdo, and H. Quintanilla, in Effect of Reel-Laying Simulation on Mechanical Performance of Flowlines. Proceedings of International Pipeline Conference, Calgary, Canada, 2006, Paper No. 10364

T. Tkaczyk, A. Pépin, and S. Denniel, in Fatigue and Fracture of Mechanically Lined Pipes Installed by Reeling. Proceedings of 31st International Conference on Ocean, Offshore and Arctic Engineering, Rio de Janeiro, Brazil, 2012, Paper No. 83050

M.C. Jo, S.G. Lee, S.S. Sohn, K.S. Kim, W.K. Kim, C.S. Lee, and S. Lee, Effects of Coiling Temperature and Pipe-forming Strain on Yield Strength Variation after ERW Pipe Forming of API, X70 and X80 Linepipe Steels, Mater. Sci. Eng., A, 2017, 682, p 304–311

G. Khadeev, D. Ringinen, and L. Efron, Effect of Multistage Deformation During the Pipe Processing on Mechanical Properties of Steels Strength Grade X70-X80, Key Eng. Mater., 2016, 716, p 957–962

T. Sadasue, S. Igi, K. Oi, and S. Yabumoto, in Full Scale Reeling Simulation Tests of Girth Welded X60 HFW Linepipe. Proceedings of 35th International Conference on Ocean, Offshore and Arctic Engineering, Busan, South Korea, 2016, Paper No. 54678

H. Shitamoto and N. Hisamune, in Effect of Full- and Small-Scale Reeling Simulation on Mechanical Properties of Weldable 13Cr Seamless Line Pipe. Proceedings of 32nd International Conference on Ocean, Offshore and Arctic Engineering, Nantes, France, 2013, Paper No. 10681

R. Sowerby, D.K. Uko, and Y. Tomita, A Review of Certain Aspects of the Bauschinger Effect in Metals, Mater. Sci. Eng., 1979, 41(1), p 43–58

G.D. Moan and J.D. Embury, A Study of the Bauschinger Effect in Al-Cu Alloys, Acta Metall., 1979, 27(5), p 903–914

S.I. Wright, M.M. Nowell, and D.P. Field, A Review of Strain Analysis Using Electron Backscatter Diffraction, Microsc. Microanal., 2011, 17(3), p 316–329

J.C.M. Li, Possibility of Subgrain Rotation during Recrystallization, J. Appl. Phys., 1962, 33(10), p 2958–2965

M.Y. Gutkin, I.A. Ovid’ko, and N.V. Skiba, Crossover from Grain Boundary Sliding to Rotational Deformation in Nanocrystalline Materials, Acta Mater., 2003, 51(14), p 4059–4071

O.A. Ruano, J. Wadsworth, and O.D. Sherby, Deformation of the Fine-grained Alumina by Grain Boundary Sliding Accommodated by Slip, Acta Mater., 2003, 51(12), p 3617–3634

I. Sabirov, Y. Estrin, M.R. Barnett, I. Timokhina, and P.D. Hodason, Tensile Deformation of an Ultrafine-grained Aluminium Alloy: Micro Shear Banding and Grain Boundary Sliding, Acta Mater., 2008, 56(10), p 2223–2230

M. Zecevic and M. Knezevic, A Dislocation Density Based Elasto-plastic Self-consistent Model for the Prediction of Cyclic Deformation: Application to AA6022-T4, Int. J. Plast, 2015, 72, p 200–217

M. Zecevic, Y.P. Korkolis, T. Kuwabara, and M. Knezevic, Dual-phase Steel Sheets under Cyclic Tension-Compression to Large Strains: Experiments and Crystal Plasticity Modeling, J. Mech. Phys. Solids, 2016, 96, p 65–87

M.E. Kassner, P. Geantil, and L.E. Levine, Long Range Internal Stresses in Single-phase Crystalline Materials, Int. J. Plast, 2013, 45, p 44–60

M.E. Kassner, P. Geantil, L.E. Levine, and B.C. Larson, in Backstress, the Bauschinger Effect and Cyclic Deformation, Materials Science Forum (2009)

S.S. Sohn, S.Y. Han, S.Y. Shin, J. Bae, and S. Lee, Effects of Microstructure and Pre-strain on Bauschinger Effect in API, X70 and X80 Linepipe Steels, Met. Mater. Int., 2013, 19(3), p 423–431

M. Calcagnotto, D. Ponge, E. Demir, and D. Raabe, Orientation Gradients and Geometrically Necessary Dislocations in Ultrafine Grained Dual-phase Steels Studied by 2D and 3D EBSD, Mater. Sci. Eng., A, 2010, 527(10–11), p 2738–2746

J. Hidalgo and M.J. Santofimia, Effect of Prior Austenite Grain Size Refinement by Thermal Cycling on the Microstructural Features of As-quenched Lath Martensite, Metall. Mater. Trans. A, 2016, 47(11), p 5288–5301

Acknowledgments

The authors acknowledge the financial support from the National Key Research and Development Program of China (Grant No. 2018YFC0310305), the National Natural Science Foundation of China (Grant Nos. 51774213 and 51804217), and the Regional Demonstration Project of Marine Economy Innovation and Development (Grant No. BHSF2017-10).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, Y., Li, C., Di, X. et al. Deformation Behavior and Microstructural Evolution of Reeled Pipeline Steels during Cyclic Plastic Deformation. J. of Materi Eng and Perform 28, 6449–6457 (2019). https://doi.org/10.1007/s11665-019-04376-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04376-6