Abstract

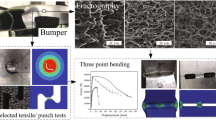

The reel-lay method is a process commonly used for rigid riser installation. During this process, riser materials are subjected to high strain levels and associated plastic damage which can affect their structural integrity. The aim of this work was to evaluate the fracture surfaces at weld metal and heat-affected zone regions of API X-80 steel three-point bend specimens, SE(B), subjected to reel-lay method simulations. The pre-existence of circumferential planar defects at 12 o’clock position was considered and the J-integral was used to simulate the reel-lay condition at the defects. Different strain levels considering conditions less and more severe than the real one were also studied. The results showed a great influence of J magnitude on fracture surface morphology. The increase of J magnitude led to a greater local surface damage on the specimens and stable crack growth during reel-lay simulation. High loading conditions should be avoided in the operation in order to prevent further structural damage of the materials.

Similar content being viewed by others

Abbreviations

- a :

-

Crack length/crack size (mm)

- a ef :

-

Effective crack size (Irwin’s first order correction) (mm)

- a n :

-

Machined notch length (mm)

- b :

-

Uncracked ligament (mm)

- B :

-

Specimen thickness (mm)

- BM:

-

Base material

- BM(L):

-

Tensile test specimen of base material (longitudinal to rolling direction)

- BM(T):

-

Tensile test specimen of base material (transversal to rolling direction)

- da/dN :

-

Fatigue crack propagation rate (mm/cycle)

- E′ :

-

Elastic modulus for plane stress (GPa)

- EPRI:

-

Electric Power Research Institute

- GTAW:

-

Gas tungsten arc welding

- h :

-

Notch height (mm)

- h 1 :

-

Function for J p according to EPRI procedure

- HAZ:

-

Heat-affected zone

- J :

-

Fracture resistance in terms of J-integral

- J e :

-

Elastic component of J (kJ/m2)

- J p :

-

Plastic component of J (kJ/m2)

- J tot :

-

Sum of elastic and plastic components of J (kJ/m2)

- K :

-

Strain hardening exponent from Ramberg-Osgood equation

- K I :

-

Stress intensity factor in mode I of loading (MPa m1/2)

- n :

-

Strain hardening coefficient from Ramberg-Osgood equation

- P :

-

Load (N)

- P 0 :

-

Reference load (N)

- R :

-

Stress ratio

- S :

-

Distance between specimen rollers equal to 4W (mm)

- SMAW:

-

Shielded metal arc welding

- SE(B):

-

Three-point bending specimen

- SEM:

-

Scanning electron microscopy

- W :

-

Specimen width (mm)

- WM:

-

Weld metal

- WM(L):

-

Tensile test specimen of weld metal region (longitudinal to weld direction)

- WM(T):

-

Tensile test specimen of weld metal region (transversal to weld direction)

- α:

-

Constant of Ramberg-Osgood equation

- ΔK :

-

Stress intensity factor range (MPa m1/2)

- εfracture :

-

Strain at fracture

- ε0 :

-

Strain at yield point

- σYS(upper) :

-

Upper yield strength (MPa)

- σYS(lower) :

-

Lower yield strength (MPa)

- σTS(upper) :

-

Tensile strength (MPa)

- σ0 :

-

Stress at yield point (MPa)

References

T.M. Ahmed, Some Considerations on Fatigue Behavior of Metals: Implications on Fatigue Life Assessment. 21st International Offshore and Polar Engineering Conference, USA, 2011, p. 262–268.

K. Higuchi and H. Shitamoto, Mechanical Properties after Full-Scale Reeling Simulation of X65 Equivalent Grade Seamless Pipe. 20th International Offshore and Polar Engineering Conference, China, 2010, p. 15–20.

B. Nyhus, E. Østby, Z. Zhang, E. Olsø, P.A. Røstadsand, and P.A. Eikrem, Large Scale Tests of Strain Capacity of Pipe Sections with Circumferential Defects Subjected to Installation-Induced Plastic Strain History. 28th International Conference on Ocean, Offshore and Artic Engineering, OMAE’09, USA, 2009, p. 1–8.

E. Østby, P.-A. Kane, and B. Nyhus, Small-scale Studies of the Effects of Pre-deformation and Ageing on the Ductile Tearing Resistance. 22nd International Offshore and Polar Engineering Conference, Greece, 2012, p. 471–478.

E. Olsø, B. Nyhus, E. Øbsty, M. Hval, and H.O. Knagenhjelm, Assessment of Fracture Integrity for Trawl Impact of the Ormen Lange SFD Pipelines. 28th International Conference on Offshore Mechanics and Artic Engineering, OMAE’09, USA, 2009.

ASTM E 8M, Standard Test Method for Tension Testing of Metallic Materials, 2008, ASTM.

W. Ramberg and W.R. Osgood, Description of Stress-strain Curves by Three Parameters, Technical Note No. 902, National Advisory Committee for Aeronautics, Washington DC, United States, 1943

C. Ruggieri and G.H.B. Donato, Metodologia para Análise de Fadiga em Risers Rígidos (SCRs) Instalados pelo Método Carretel, USP, 2008.

ISO 12108, Metallic Materials – Fatigue Testing – Fatigue Crack Growth Method, ISO 12108, ISO, 2002.

T.L. Anderson, Fracture Mechanics: Fundamentals and Applications. 2nd ed., CRC Press, Boca Raton, FL, USA, 2005.

N. Bajic, V. Sijacki-Zeravcic, B. Bobic, D. Cikara, and M. Arsic, Filler Metal Influence on Weld Metal Structure of Microalloyed Steel, Suppl. Weld. J., 2011, 90, p 55s–62s

E.S. Surian, N.M. Ramini de Rissone, H.G. Svoboda, R. Rep, and L.A. de Vedia, SMAW, FCAW and SAW High-Strength Ferritic Deposits: The Challenge is Tensile Properties, Weld. J., 2010, 89, p 54s–64s

J.O. Olawale, S.A. Ibitoye, K.M. Oluwasegum, M.D. Shittu, and R.C. Ofoezie, Correlation between Process Variables in Shielded Metal-Arc Welding (SMAW) Process and Post Weld Heat Treatment (PWHT) on Some Mechanical Properties of Low Carbon Steel Welds, J. Miner. Mater. Charact. Eng., 2012, 11, p 891–895

M.A.N. Beltrão, Fatigue Crack Propagation of Longitudinal Welded Joints of Pipeline API 5L X-70 Grade Steel, M.Sc. Dissertation, COPPE/UFRJ, Rio de Janeiro, Brazil, 2005 (in Portuguese).

X.B. Ren, Z.L. Zhang, and B. Nyhus, Effect of Residual Stresses on a Ductile Crack Growth Resistance, Eng. Fract. Mech., 2010, 77(8), p 1325–1337

F. Scheyvaerts, T. Pardoen, and P.R. Onck, A New Model for Void Coalescence by Internal Necking, Int. J. Damage Mech., 2010, 19(1), p 95–126

K. Enami, The Effects of Compressive and Tensile Prestrain on Ductile Fracture Initiation in Steels, Eng. Fract. Mech., 2005, 72, p 1089–1105

M. Ohata and M. Toyoda, Damage Concept for Evaluating Ductile Cracking of Steel Structure Subjected to Large-Scale Cyclic Straining, Sci. Technol. Adv. Mater., 2004, 5, p 241–249

X.Y. Wu, K.T. Ramesh, and T.W. Wright, The Coupled Effects of Plastic Strain Gradient and Thermal Softening on the Dynamic Growth of Voids, Int. J. Solids Struct., 2003, 40(24), p 6633–6651

F.-R. Xiao, B. Liao, Y.-Y. Shan, G.-Y. Qiao, Y. Zhong, C. Zhang, and Y. Yang, Challenge of Mechanical Properties of an Acicular Ferrite Pipeline Steel, Mater. Sci. Eng. A, 2006, 1–2, p 41–52

Y. Zhong, F. Xiao, J. Zhang, Y. Shan, W. Wang, and K. Yang, In situ TEM Study of the Effect of M/A Films at Grain Boundaries on Crack Propagation in an Ultra-fine Acicular Ferrite Pipeline Steel, Acta Mater., 2006, 54, p 435–443

Y. Zhong, Y. Shan, F. Xiao, and K. Yang, Effect of Toughness on Low Cycle Fatigue Behavior of Pipeline Steels, Mater. Lett., 2005, 59, p 1780–1784

H.K. Lee, K.S. Kim, and C.M. Kim, Fracture Resistance of a Steel Weld Joint under Fatigue Loading, Eng. Fract. Mech., 2000, 66, p 403–419

X.B. Ren, Z.L. Zhang, and B. Nyhus, Effect of Residual Stresses on the Crack-Tip Constraint in a Modified Boundary Layer Model, Int. J. Solids Struct., 2009, 46, p 2629–2641

M. Farahani and I. Sattari-Far, Effects of Residual Stresses on Crack-tip Constraints, Scientia Iranica B, 2011, 18(6), p 1267–1276

J. Liu, Z.L. Zhang, and B. Nyhus, Residual Stress Induced Crack Tip Constraint, Eng. Fract. Mech., 2008, 75, p 4151–4166

Acknowledgments

The authors would like to thank PETROBRAS especially Dr. Guilherme Donato and Dr. Eduardo Hippert, the Fracture Mechanics and Structural Integrity group of University of São Paulo especially Prof. Claudio Ruggieri and Gustavo Donato, Dr. Marcelo Moraes from NUCLEP and CNPq and FAPERJ.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Beltrão, M.A.N., Bastian, F.L. Fractographic Analysis of Weld Metal and HAZ Regions of API X-80 Steel Subjected to Simulation of the Reel-Lay Method. J. of Materi Eng and Perform 23, 3523–3533 (2014). https://doi.org/10.1007/s11665-014-1158-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1158-6