Abstract

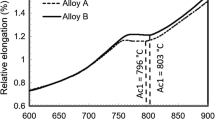

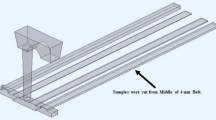

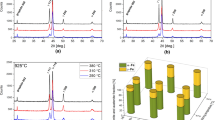

The effects of Ni content and austempering temperature on microstructural evolution during austempering in solution-strengthened ferritic ductile cast iron with Ni contents between 0 and 1.1 mass% were investigated. The microstructure observation for the samples austempered at temperatures between 375 and 325 °C using an infrared gold image furnace was carried out with optical microscopy, x-ray diffraction measurements, and electron back-scattered diffraction pattern (EBSP) analysis. In addition, the Vickers hardness of both the austempered and as-quenched samples was measured under a load of 0.9807 N. According to the microstructure observations, the matrix of the samples austempered at temperatures between 375 and 325 °C exhibited finer acicular ferrite microstructure with increasing Ni content. Optical microscopy and EBSP analysis revealed that the amount of high-carbon austenite phase for the austempered samples increased with increasing Ni content and austempering temperature. Although samples with higher Ni content were found to contain more high-carbon austenite phase in the matrix, the Vickers hardness of the samples tended to increase with increasing Ni content at the same austempering temperature. The reason for this may be the higher carbon content in the matrix of the samples with higher Ni contents.

Similar content being viewed by others

References

Y. Tanaka and H. Kage, Development and Application of Austempered Spheroidal Graphite Cast Iron, Mater. Trans., JIM, 1992, 33(6), p 543–557

J. Dodd, High Strength, High ductility, Ductile irons, Mod. Cast., 1978, 68(5), p 60–66

R.B. Gundlach and J.F. Janowak, Development of a Ductile Iron for Commercial Austempering, AFS Trans., 1983, 94, p 377–388

R.A. Harding and G.N.J. Gilbert, Why the Properties of Austempered Ductile Irons Should Interest Engineers, Br. Foundryman, 1986, 79, p 489–496

J.L. Doong and C. Chen, Fracture Toughness of Bainitic Nodular Cast Iron, Fatigue Fract. Eng. Mater. Struct., 1989, 12(2), p 155–165

S.K. Putatunda and I. Singh, Fracture Toughness of Unalloyed Austempered Ductile Cast Iron (ADI), J. Test. Eval., 1995, 23(5), p 325–332

P.P. Rao and S.K. Putatunda, Influence of Microstructure on Fracture Toughness of Austempered Ductile Iron, Metall. Mater. Trans. A, 1997, 28(7), p 1457–1470

P.P. Rao and S.K. Putatunda, Comparative Study of Fracture Toughness of Austempered Ductile Irons with Upper and Lower Ausferrite Microstructures, Mater. Sci. Technol., 1998, 14(12), p 1257–1265

P.P. Rao and S.K. Putatunda, Dependence of Fracture Toughness of Austempered Ductile Iron on Austempering Temperature, Metall. Mater. Trans. A, 1998, 29(12), p 3005–3016

I. Schmidt and A. Schuchert, Unlubricated Sliding Wear of Austempered Ductile Iron, Z. Metallkd., 1987, 78(12), p 871–875

T. Kobayashi and H. Yamamoto, Development of High Toughness in Austempered Type Ductile Cast Iron and Evaluation of Its Properties, Metall. Trans. A, 1988, 19(2), p 319–327

Y. Mi, Effect of Cu, Mo, Si on the Content of Retained Austenite of Austempered Ductile Iron, Scr. Metall. Mater., 1995, 32(9), p 1313–1317

J. Yang and S.K. Putatunda, Improvement in Strength and Toughness of Austempered Ductile Cast Iron by a Novel Two-Step Austempering Process, Mater. Des., 2004, 25(3), p 219–230

A.S. Benam, Effect of Alloying Elements on Austempered Ductile Iron (ADI) Properties and Its Process: Review, China Foundry, 2015, 12(1), p 54–70

S. Panneerselvam, C.J. Martis, S.K. Putatunda, and J.M. Boileau, An Investigation on the Stability of Austenite in Austempered Ductile Cast Iron (ADI), Mater. Sci. Eng., A, 2015, 626, p 237–246

S. Panneerselvam, S.K. Putatunda, R. Gundlach, and J. Boileau, Influence of Intercritical Austempering on the Microstructure and Mechanical Properties of Austempered Ductile Cast Iron (ADI), Mater. Sci. Eng., A, 2017, 694, p 72–80

P. Sellamuthu, D.G. Harris Samuel, D. Dinakaran, V.P. Premkumar, Z. Li, and S. Seetharaman, Austempered Ductile Iron (ADI): Influence of Austempering Temperature on Microstructure, Mechanical and Wear Properties and Energy Consumption, Metals, 2018, 8(1), art. no. 53

R. Larker, Solution Strengthened Ferritic Ductile Iron ISO 1083/JS/500-10 Provides Superior Consistent Properties in Hydraulic Rotators, China Foundry, 2009, 6(4), p 343–351

T. Tokunaga, T. Furukawa, and H. Era, Effect of Ni Content on the Ferrite-to-Austenite Transformation during Austenitising in Spheroidal Graphite Cast Iron, Reports of the 167th JFS Meeting, 2015, p 63–64 (in Japanese)

K. Shinoda and T. Yamada, Mechanical Properties of a Si-Mn Steel with Mixed Structure of Bainite and Retained Austenite, J. Jpn. Soc. Heat Treat., 1980, 20(7), p 326–330 (in Japanese)

K. Tsuzaki and T. Maki, Stabilization of Austenite in Steels, J. Jpn. Soc. Heat Treat., 1992, 32(1), p 10–15 (in Japanese)

H.K.D.H. Bhadeshia and R.W.K. Honeycombe, Steels, Microstructure and Properties, 3rd ed., Butterworth-Heinemann, Burlington, 2006, p 146–147

K. Ogi, A. Sawamoto, and J. Hiwatashi, Transformation Process and Behavior of Carbon in Austempering Heat Treatment of Spheroidal Graphite Cast Iron, J. JFS., 1988, 60(4), p 233–239 (in Japanese)

H.K.D.H. Bhadeshia, Bainite in Steels, Theory and Practice, 3rd ed., Maney Publishing, Leeds, 2015, p 446

F.B. Pickering, Physical Metallurgy and the Design of Steels, Applied Science Publishers, London, 1983, p 12

Acknowledgments

The authors are grateful to Hinode, Ltd., Japan, for providing the materials used in this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tokunaga, T., Kim, YJ. & Era, H. Effect of Nickel Content on Microstructural Evolution in Austempered Solution-Strengthened Ferritic Ductile Cast Iron. J. of Materi Eng and Perform 28, 4034–4040 (2019). https://doi.org/10.1007/s11665-019-04184-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04184-y