Abstract

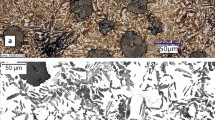

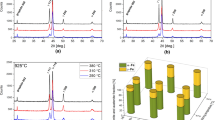

In order to increase the toughness of austempered ductile cast irons, we attempted to strengthen the fracture initiation sites such as graphite-matrix interfaces and eutectic cell boundaries in a way of the microsegregation of alloying elements. For instance, the retained austenite which is stable under external stresses may be introduced preferentially into these sites by the addition of Ni, which segregates to a graphite periphery and of Mn, which partitions mainly to eutectic cell boundaries. Following this concept, the effects of various austempering processes on toughness are also in-vestigated. The cast iron alloying with Ni and Mn shows the best fracture toughness when it is heat-treated by either QB' or B' process; here, the QB' means the oil-quenching from an austenite γ phase range followed by austempering from a ferrite α plus γ range and the B' means austempering from a (α + γ) range. In the newly developed iron, there is a mixed microstructure composed of the ferrite, bainitic ferrite, and austenite. Abnormal elongation due to the TRIP effect in the austenite phase is found to have occurred at about 198 K. Moreover, it is shown that this TRIP effect may be caused by the formation of deformation twins.

Similar content being viewed by others

References

J.F. Janowak and R.B. Gundlack:AFS Trans., 1983,vol. 91,p. 377.

E. Dorazil, B. Barta, L. Stransky, E. Munsterova, and A. Huvar:Giesserei-Praxis, 1982, vol. 19, p. 303.

R. B. Gundlack and J. F. Janowak:Metal Progress, 1985, vol. 128, p. 19.

M. Johansson:AFS Trans., 1977, vol. 85, p. 117.

T. Kobayashi:Kinzoku-Gakkai-hάcro, 1983, vol. 45, p. 155.

T. Kobayashi and S. Nishi:Imono (in English), 1980, vol. 52, p. 76.

Lo-Kan:Fonderie, 1977, vol. 367, p. 167.

S. Nagashima, T. Ooka, S. Sekino, H. Mimura, T. Fujishima, S. Yano, and H. Sakurai:Trans. IS1J, 1971, vol. 58, p. 402.

T. Kobayashi and H. Tachibana:Trans. JIM, 1983, vol. 24, p. 281.

R. O. Ritchie and A. W. Thompson:Metall. Trans. A, 1985, vol. 16A, p. 233.

T. Kobayashi:Eng. Frac. Mech., 1984, vol. 19, p. 49.

T. Kobayashi, I. Yamamoto, and M. Niinomi:Eng. Frac. Mech., 1986, vol. 24, p. 733.

T. Kobayashi, I. Yamamoto, and M. Niinomi:Proc. 9th Cong. Mat. Testing, Budapest, 1986, vol. I, p. 75.

H. K. D. H. Bhadeshia and D. V. Edmonds:Met. Sci., 1983, vol. 17, p. 411.

T. Fujita, H. Misawa, and H. Tsutsumi:Tetsu-to-Hagané, 1972, vol. 58, p. 1693.

A. Ikenaga and K. Okabayashi:Imono, 1980, vol. 52, p. 263.

I. Tamura and T. Maki:Toward Improved Ductility and Toughness, Climax Mo. Co. Ltd., Japan, 1971, p. 183.

C. H. White and P. W. K. Honeycombe:JISI, 1962, vol. 202, p. 457.

Y. N. Dastur and W. C. Leslie:Metall. Trans. A, 1981, vol. 12A, p. 749.

T. Kobayashi, W. Yagi, T. Kajino, and Y. Ueda:Tetsu-to-Hagané, 1984, vol. 70, p. 861.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kobayashi, T., Yamamoto, H. Development of high toughness in austempered type ductile cast iron and evaluation of its properties. Metall Trans A 19, 319–327 (1988). https://doi.org/10.1007/BF02652541

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02652541