Abstract

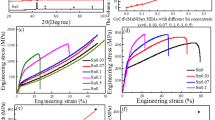

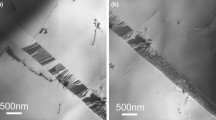

High-entropy alloys (HEAs), a novel class of metal alloys, have been receiving increasing attention from the scientific community. HEAs have the potential to be used in critical load-bearing applications in replacement of conventional alloys such as stainless steel and nickel-base superalloys. Tensile experiments at quasi-static to dynamic strain rates (10−4-103 s−1) were performed on two single-phase face-centered cubic HEAs, CoCrFeNi and CoCrFeMnNi. Electron backscatter diffraction was used to study the microstructure of the samples before the experiments, and transmission electron microscopy was performed postmortem. The dominant deformation mechanisms were dislocation slip at quasi-static strain rates with the addition of deformation nano-twins at dynamic strain rates. Ultimate dynamic tensile strength and ductility improved with the increase in strain rate, which can be attributed to the activation of deformation nano-twins in HEAs. CoCrFeNi and CoCrFeMnNi both have low stacking fault energies, which could promote twinning at high strain rates to accommodate plastic deformation. The strain rate sensitivity of the flow stress increased with increasing strain rate, beginning with negligible strain rate sensitivity in the quasi-static range to high strain rate sensitivity in the dynamic range. CoCrFeMnNi showed greater strain rate sensitivity of flow stress. CoCrFeNi, with less configurational entropy, had higher mechanical properties and strain-hardening rates compared to CoCrFeMnNi, which was attributed to the weakening effect of the addition of Mn on the solid solution hardening.

Similar content being viewed by others

References

E.J. Pickering and N.G. Jones, High-Entropy Alloys: A Critical Assessment of Their Founding Principles and Future Prospects, Int. Mater. Rev., 2016, 61, p 183–202

F. Otto, A. Dlouhy, C. Somsen, H. Bei, G. Eggeler, and E.P. George, The Influences of Temperature and Microstructure on the Tensile Properties of a CoCrFeMnNi High-Entropy Alloy, Acta Mater., 2013, 61(15), p 5743–5755. https://doi.org/10.1016/j.actamat.2013.06.018

A. Gali and E.P. George, Tensile Properties of High- and Medium-Entropy Alloys, Intermetallics, 2013, 39, p 74–78. https://doi.org/10.1016/j.intermet.2013.03.018

G. Laplanche, A. Kostka, O.M. Horst, G. Eggeler, and E.P. George, Microstructure Evolution and Critical Stress for Twinning in the CrMnFeCoNi High-Entropy Alloy, Acta Mater., 2016, 118, p 152–163. https://doi.org/10.1016/j.actamat.2016.07.038

G. Laplanche, A. Kostka, C. Reinhart, J. Hunfeld, G. Eggeler, and E.P. George, Reasons for the Superior Mechanical Properties of Medium-Entropy CrCoNi Compared to High-Entropy CrMnFeCoNi, Acta Mater., 2017, 128, p 292–303. https://doi.org/10.1016/j.actamat.2017.02.036

W. Huo, H. Zhou, F. Fang, X. Hu, Z. Xie, and J. Jiang, Strain-Rate Effect upon the Tensile Behavior of CoCrFeNi High-Entropy Alloys, Mater. Sci. Eng. A, 2017, 689, p 366–369

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, and R.O. Ritchie, A Fracture-Resistant High-Entropy Alloy for Cryogenic Applications, Science, 2014, 345, p 1153–1158

J.J. Licavoli, M.C. Gao, J.S. Sears, P.D. Jablonski, and J.A. Hawk, Microstructure and Mechanical Behavior of High-Entropy Alloys, J. Mater. Eng. Perform., 2015, 24(10), p 3685–3698. https://doi.org/10.1007/s11665-015-1679-7

G.R. Holcomb, J. Tylczak, and C. Carney, Oxidation of CoCrFeMnNi High Entropy Alloys, JOM, 2015, 67, p 2326–2339

N. Kumar, Q. Ying, X. Nie, R.S. Mishra, Z. Tang, P.K. Liaw, R.E. Brennan, K.J. Doherty, and K.C. Cho, High Strain-Rate Compressive Deformation Behavior of the Al0.1CrFeCoNi High Entropy Alloy, Mater. Des., 2015, 86, p 598–602

J.W.-W. Yeh, S.-K.K. Chen, S.-J.J. Lin, J.-Y.Y. Gan, T.S.-S. Chin, T.-T.T. Shun, C.-H.H. Tsau, and S.Y.-Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303. https://doi.org/10.1002/adem.200300567

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004, 375–377, p 213–218. https://doi.org/10.1016/j.msea.2003.10.257

M.A. Hemphill, T. Yuan, G.Y. Wang, J.W. Yeh, C.W. Tsai, A. Chuang, and P.K. Liaw, Fatigue Behavior of Al0.5CoCrCuFeNi High Entropy Alloys, Acta Mater., 2012, 60(16), p 5723–5734. https://doi.org/10.1016/j.actamat.2012.06.046

H.Y. Diao, R. Feng, K.A. Dahmen, and P.K. Liaw, Fundamental Deformation Behavior in High-Entropy Alloys: An Overview, Curr. Opin. Solid State Mater. Sci., 2017, 21(5), p 252–266. https://doi.org/10.1016/j.cossms.2017.08.003

E. Eshed, N. Larianovsky, A. Kovalevsky, and A. Katz Demyanetz, Effect of Zr on the Microstructure of Second- and Third-Generation BCC HEAs, JOM, 2019, 71(2), p 673–682. https://doi.org/10.1007/s11837-018-3198-0

Y. Deng, C.C. Tasan, K.G. Pradeep, H. Springer, A. Kostka, and D. Raabe, Design of a Twinning-Induced Plasticity High Entropy Alloy, Acta Mater., 2015, 94, p 124–133. https://doi.org/10.1016/j.actamat.2015.04.014

F. Otto, Y. Yang, H. Bei, and E.P. George, Relative Effects of Enthalpy and Entropy on the Phase Stability of Equiatomic High-Entropy Alloys, Acta Mater., 2013, 61, p 2628–2638

N.G. Jones, J.W. Aveson, A. Bhowmik, B.D. Conduit, and H.J. Stone, On the Entropic Stabilisation of an Al0.5CrFeCoNiCu High Entropy Alloy, Intermetallics, 2014, 54, p 148–153

P.D. Jablonski, J.J. Licavoli, M.C. Gao, and J.A. Hawk, Manufacturing of High Entropy Alloys, JOM, 2015, 67(10), p 2278–2287. https://doi.org/10.1007/s11837-015-1540-3

L. Patriarca, A. Ojha, H. Sehitoglu, and Y.I. Chumlyakov, Slip Nucleation in Single Crystal FeNiCoCrMn High Entropy Alloy, Scr. Mater., 2016, 112, p 54–57. https://doi.org/10.1016/j.scriptamat.2015.09.009

W. Abuzaid and H. Sehitoglu, Critical Resolved Shear Stress for Slip and Twin Nucleation in Single Crystalline FeNiCoCrMn High Entropy Alloy, Mater. Charact., 2017, 129, p 288–299

Z.Z. Zhang, M.M. Mao, J. Wang, B. Gludovatz, Z.Z. Zhang, S.X. Mao, E.P. George, Q. Yu, and R.O. Ritchie, Nanoscale Origins of the Damage Tolerance of the High-Entropy Alloy CrMnFeCoNi, Nat. Commun., 2015, 6(1), p 10143. https://doi.org/10.1038/ncomms10143

S.Y. Lee, S.I. Lee, and B. Hwang, Effect of Strain Rate on Tensile and Serration Behaviors of an Austenitic Fe-22Mn-0.7C Twinning-Induced Plasticity Steel, Mater. Sci. Eng. A, 2018, 711, p 22–28

D. Barbier, N. Gey, S. Allain, N. Bozzolo, and M. Humbert, Analysis of the Tensile Behavior of a TWIP Steel Based on the Texture and Microstructure Evolutions, Mater. Sci. Eng. A, 2009, 500, p 196–206

O. Bouaziz, S. Allain, C.P. Scott, P. Cugy, and D. Barbier, High Manganese Austenitic Twinning Induced Plasticity Steels: A Review of the Microstructure Properties Relationships, Curr. Opin. Solid State Mater. Sci., 2011, 15, p 141–168

D.R. Steinmetz, T. Jäpel, B. Wietbrock, P. Eisenlohr, I. Gutierrez-Urrutia, A. Saeed-Akbari, T. Hickel, F. Roters, D. Raabe, A. Saeed-Akbari, T. Hickel, F. Roters, and D. Raabe, Revealing the Strain-Hardening Behavior of Twinning-Induced Plasticity Steels: Theory, Simul. Exp. Acta Mater., 2013, 61(2), p 494–510

I. Karaman, H. Sehitoglu, K. Gall, Y.I. Chumlyakov, and H.J. Maier, Deformation of Single Crystal Hadfield Steel by Twinning and Slip, Acta Mater., 2000, 48, p 1345–1359

B. Wang, A. Fu, X. Huang, B. Liu, Y. Liu, Z. Li, and X. Zan, Mechanical Properties and Microstructure of the CoCrFeMnNi High Entropy Alloy Under High Strain Rate Compression, J. Mater. Eng. Perform., 2016, 25(7), p 2985–2992

J.M. Park, J. Moon, J.W. Bae, M.J. Jang, J. Park, S. Lee, and H.S. Kim, Strain Rate Effects of Dynamic Compressive Deformation on Mechanical Properties and Microstructure of CoCrFeMnNi High-Entropy Alloy, Mater. Sci. Eng. A, 2018, 719, p 155–163

M.A. Meyers, Dynamic Behavior of Materials, Wiley, New York, 1994

G.T. Gray, Classic Split-Hopkinson Pressure Bar Testing, in ASM Handbook Vol. 8: Mechanical Testing and Evaluation, 2000

K.T. Ramesh, Chapter 33. High Strain Rate and Impact Experiments, in Springer Handbook of Experimental Solid Mechanics, 2008

W. Chen and B. Song, Split Hopkinson (Kolsky) Bar: Design, Testing and Applications, Springer, New York, 2011

S. Mahajan, C.S. Pande, M.A. Imam, and B.B. Rath, Formation of Annealing Twins in f.c.c. Crystals, Acta Mater., 1997, 45, p 2633–2638

R.L. Fullman and J.C. Fisher, Formation of Annealing Twins during Grain Growth, J. Appl. Phys., 1951, 21, p 1350–1355

R.W. Hertzberg, Deformation and Fracture Mechanics of Engineering Materials, Wiley, New York, 1996

M. Komarasamy, N. Kumar, R.S. Mishra, and P.K. Liaw, Anomalies in the Deformation Mechanism and Kinetics of Coarse-Grained High Entropy Alloy, Mater. Sci. Eng. A, 2016, 654, p 256–263

J. Moon, S.I. Hong, J.W. Bae, M.J. Jang, D. Yim, and H.S. Kim, On the Strain Rate-Dependent Deformation Mechanism of CoCrFeMnNi High-Entropy Alloy at Liquid Nitrogen Temperature, Mater. Res. Lett., 2017, 5, p 427–477

D.M. Bruce, D.K. Matlock, J.G. Speer, and A.K. De, Assessment of the Strain-Rate Dependent Tensile Properties of Automotive Sheet Steels, SAE Technical Paper, 2004

J.D. Campbell and W.G. Ferguson, The Temperature and Strain-Rate Dependence of the Shear Strength of Mild Steel, Philos. Mag., 1970, 21, p 63–82

B.L. Boyce and M.F. Dilmore, The Dynamic Tensile Behavior of Tough, Ultrahigh-Strength Steels at Strain-Rates from 0.0002 s−1 to 200 s−1, Int. J. Impact Eng., 2009, 36, p 263–271

N. Tsuchida, Y. Izaki, T. Tanaka, and K. Fukaura, Effects of Temperature and Strain Rate on Stress-Strain Curves for Dual-Phase Steels and Their Calculations by Using the Kocks–Mecking Model, ISIJ Int., 2011, 97, p 201–208

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Solid-Solution Phase Formation Rules for Multi-Component Alloys, Adv. Eng. Mater., 2008, 10, p 534–538

G.A. Salishchev, M.A. Tikhonovsky, D.G. Shaysultanov, N.D. Stepanov, A.V. Kuznetsov, I.V. Kolodiy, A.S. Tortika, and O.N. Senkov, Effect of Mn and v on Structure and Mechanical Properties of High-Entropy Alloys Based on CoCrFeNi System, J. Alloys Compd., 2014, 591, p 11–21

N.L. Okamoto, K. Yuge, K. Tanaka, H. Inui, and E.P. George, Atomic Displacement in the CrMnFeCoNi High-Entropy Alloy—A Scaling Factor to Predict Solid Solution Strengthening, AIP Adv., 2016, 6, p 125008-(1-8)

S.H. Joo, H. Kato, M.J. Jang, J. Moon, C.W. Tsai, J.W. Yeh, and H.S. Kim, Tensile Deformation Behavior and Deformation Twinning of an Equimolar CoCrFeMnNi High-Entropy Alloy, Mater. Sci. Eng. A, 2017, 689, p 122–133

S.R. Kalidindi, A.A. Salem, and R.D. Doherty, Role of Deformation Twinning on Strain Hardening in Cubic and Hexagonal Polycrystalline Metals, Adv. Eng. Mater., 2003, 5, p 229–232

Z.S.S. Basinski, M.S.S. Szczerba, M. Niewczas, J.D.D. Embury, and S.J.J. Basinski, Transformation of Slip Dislocations during Twinning of Copper-Aluminum Alloy Crystals, Rev. Metall. Cah. D’Inf. Tech., 1997, 94, p 1037–1043

M. Beyramali Kivy and M. Asle Zaeem, Generalized Stacking Fault Energies, Ductilities, and Twinnabilities of CoCrFeNi-Based Face-Centered Cubic High Entropy Alloys, Scr. Mater., 2017, 139, p 83–86. https://doi.org/10.1016/j.scriptamat.2017.06.014

Y. Wang, B. Liu, K. Yan, M. Wang, S. Kabra, Y.-L. Chiu, D. Dye, P.D. Lee, Y. Liu, and B. Cai, Probing Deformation Mechanisms of a FeCoCrNi High-Entropy Alloy at 293 and 77 K Using in Situ Neutron Diffraction, Acta Mater., 2018, 154, p 79–89

C. Zener and J.H. Hollomon, Effect of Strain Rate upon Plastic Flow of Steel, J. Appl. Phys., 1944, 15, p 22–32

Z. Li, S. Zhao, S.M. Alotaibi, Y. Liu, B. Wang, and M.A. Meyers, Adiabatic Shear Localization in the CrMnFeCoNi High-Entropy Alloy, Acta Mater., 2018, 151, p 424–431

Z. Wu, H. Bei, G.M. Pharr, and E.P. George, Temperature Dependence of the Mechanical Properties of Equiatomic Solid Solution Alloys with Face-Centered Cubic Crystal Structures, Acta Mater., 2014, 81, p 428–441

W.-M. Choi, Y.H. Jo, S.S. Sohn, S. Lee, and B.-J. Lee, Understanding the Physical Metallurgy of the CoCrFeMnNi High-Entropy Alloy: An Atomistic Simulation Study, npj Comput. Mater., 2018, 4(1), p 1. https://doi.org/10.1038/s41524-017-0060-9

Acknowledgments

The authors would like to acknowledge NETL for preparing and supplying the high-entropy alloys and Clemson University AMRL facility for assistance with microscopy.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shabani, M., Indeck, J., Hazeli, K. et al. Effect of Strain Rate on the Tensile Behavior of CoCrFeNi and CoCrFeMnNi High-Entropy Alloys. J. of Materi Eng and Perform 28, 4348–4356 (2019). https://doi.org/10.1007/s11665-019-04176-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04176-y