Abstract

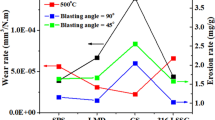

In this work, AISI 316 stainless steel (316 SS) was electrochemically etched in four NaCl solutions (10, 15, 20, and 25 wt.%) to form textured surfaces. Surface morphologies, three-dimensional surface topographies, and surface profiles of the textured 316 SS samples were obtained by scanning electron microscopy (SEM) and laser scanning confocal microscope (LSCM). Sliding friction tests of the textured 316 SS samples were conducted in air and under grease lubrication. The results suggested that the variable degrees of microtextured surfaces after electrochemical etching in 10, 15, and 20 wt.% NaCl solutions. The 316 SS samples etched in 15 and 20 wt.% NaCl solutions showed more promising tribological performance than other samples, as reflected by their friction coefficients, mass loss per unit distance traveled (mg/m), and wear morphologies.

Similar content being viewed by others

References

Y.X. Gao and S.M. Zheng, Effect of Plasma Nitriding Temperature on Characteristic of AISI, 201 Austenitic Stainless Steel, Surf. Rev. Lett., 2016, 23(1550084), p 1–8

C.Y. Cui, X.G. Cui, X.D. Ren, M.J. Qi, J.D. Hu, and Y.M. Wang, Surface Oxidation Phenomenon and Mechanism of AISI, 304 Stainless Steel Induced by Nd: YAG Pulsed Laser, Appl. Surf. Sci., 2014, 305, p 817–824

B. Federico, W. Grethe, L.C. Thomas, and A.J.S. Marcel, Influence of Plastic Deformation on Low-Temperature Surface Hardening of Austenitic Stainless Steel by Gaseous Nitriding, Metall. Mater. Trans. A, 2015, 46, p 2579–2590

A.F. Yetim, M.Y. Codur, and M. Yazici, Using of Artificial Neural Network for the Prediction of Tribological Properties of Plasma Nitrided 316L Stainless Steel, Mater. Lett., 2015, 158, p 170–173

F.C. Liu, Y.Q. Mao, X. Lin, B.S. Zhou, and T. Qian, Microstructure and High Temperature Oxidation Resistance of Ti–Ni Gradient Coating on TA2 Titanium Alloy Fabricated by Laser Cladding, Opt. Laser Technol., 2016, 83, p 140–147

M. Tkadletz, N. Schalk, R. Daniel, J. Keckes, C. Czettl, and C. Mitterer, Advanced Characterization Methods for Wear Resistant Hard Coatings: A Review on Recent Progress, Surf. Coat. Technol., 2016, 285, p 31–46

X.L. Zhang and J.H. Jia, Frictional Behavior of Micro/nanotextured Surfaces Investigated by Atomic Force Microscope: A Review, Surf. Rev. Lett., 2015, 22(1530001), p 1–10

W. Pfleging, R. Kumari, H. Besser, T. Scharnweber, and J.D. Majumdar, Laser Surface Textured Titanium Alloy (Ti–6Al–4V): Part 1–Surface Characterization, Appl. Surf. Sci., 2015, 355, p 104–111

N.M. Lin, Q. Liu, J.J. Zou, J.W. Guo, D.L. Li, S. Yuan, Y. Ma, Z.X. Wang, Z.H. Wang, and B. Tang, Surface Texturing–Plasma Nitriding Duplex Treatment for Improving Tribological Performance of AISI, 316 Stainless Steel, Materials, 2016, 9(875), p 1–26

G.D. Bixler and B. Bhushan, Bioinspired Rice Leaf and Butterfly Wing Surface Structures Combining Shark Skin and Lotus Effects, Soft Matter, 2012, 8, p 11271–11284

L. Wen, J.C. Weaver, and G.V. Lauder, Biomimetic Shark Skin: Design; Fabrication and Hydrodynamic Function, J. Exp. Biol., 2014, 217, p 1656–1666

K. Autumn and N. Gravish, Gecko Adhesion: Evolutionary Nanotechnology, Philos. Trans. R. Soc. Lond. Ser. A, 2008, 336, p 1575–1590

H. Zhang, L.G. Qin, M. Hua, G.N. Dong, and K.S. Chin, A Tribological Study of the Petaloid Surface Texturing for Co–Cr–Mo Alloy Artificial Joints, Appl. Surf. Sci., 2015, 332, p 557–564

Z.H. Zhang, F.X. Shao, Y.H. Liang, P.Y. Lin, X. Tong, and L.Q. Ren, Wear Behavior of Medium Carbon Steel with Biomimetic Surface Under Starved Lubricated Conditions, J. Mater. Eng. Perform., 2017, 26, p 3420–3430

M.K. Tang, X.J. Huang, J.G. Yu, X.W. Li, and Q.X. Zhang, The Effect of Textured Surfaces with Different Roughness Structures on the Tribological Properties of Al Alloy, J. Mater. Eng. Perform., 2016, 25, p 4115–4125

N.M. Lin, D.L. Li, J.J. Zou, R.Z. Xie, Z.H. Wang, and B. Tang, Surface Texture-Based Surface Treatments on Ti6Al4V Titanium Alloys for Tribological and Biological Applications: A Mini Review, Materials, 2018, 11, p 487

H.J. Yang, K. Yang, and B.C. Zhang, Pitting Corrosion Resistance of La Added 316L Stainless Steel in Simulated Body Fluids, Mater. Lett., 2007, 61, p 1154–1157

Y.M. Han and X.G. Chen, Electrochemical Behavior of Al–B4C Metal Matrix Composites in NaCl Solution, Materials, 2015, 8, p 6455–6470

P.P. Sarkar, P. Kumar, M.K. Manna, and P.C. Chakraborti, Microstructural Influence on the Electrochemical Corrosion Behaviour of Dual-Phase Steels in 3.5% NaCl Solution, Mater. Lett., 2005, 59, p 2488–2491

J.J. Zou, M.L. Li, N.M. Lin, X.Y. Zhang, L. Qin, and B. Tang, An Electrochemical Processing Strategy for Improving Tribological Performance of AISI, 316 Stainless Steel under Grease Lubrication, Surf. Rev. Lett., 2014, 21(1450006), p 1–7

L. Vandoni, A.G. Demir, B. Previtali, N. Lecis, and D. Ugues, Wear Behavior of Fiber Laser Textured TiN Coatings in a Heavy Loaded Sliding Regime, Materials, 2012, 5, p 2360–2382

T.C. Hu, Y.S. Zhang, and L.T. Hu, Tribological Investigation of MoS2 Coatings Deposited on the Laser Textured Surface, Wear, 2012, 278–279, p 77–82

W.J. Yang, M. Zhang, Y.H. Zhao, M.L. Shen, H. Lei, L. Xu, J.Q. Xiao, J. Gong, B.H. Yu, and C. Sun, Enhancement of Mechanical Property and Corrosion Resistance of 316 L Stainless Steels by Low Temperature Arc Plasma Nitriding, Surf. Coat. Technol., 2016, 298, p 64–72

Y. Yu, J. Wang, J.S. Li, J. Yang, H.C. Kou, and W.M. Liu, Tribological Behavior of AlCoCrFeNi(Ti0.5) High Entropy Alloys under Oil and MACs Lubrication, J. Mater. Sci. Technol., 2016, 32, p 470–476

N.M. Lin, F.Q. Xie, H.J. Yang, W. Tian, H.F. Wang, and B. Tang, Assessments on Friction and Wear Behaviors of P110 Steel and Chromizing Coating Sliding against Two Counterpart under Dry and Wet Conditions, Appl. Surf. Sci., 2012, 258, p 4960–4970

N.M. Lin, F.Q. Xie, J. Zhou, T. Zhong, X.Q. Wu, and W. Tian, Microstructures and Wear Resistance of Chromium Coatings on P110 Steel Fabricated by Pack Cementation, J. Cent. South Univ., 2010, 17, p 1075–1078

J.L. Li, D.S. Xiong, H.Y. Wu, Z.J. Huang, J.H. Dai, and R. Tyagi, Tribological Properties of Laser Surface Texturing and Molybdenizing Duplex-Treated Ni-Base Alloy, Tribol. Trans., 2010, 53, p 195–202

W. Tang, Y.K. Zhou, H. Zhu, and H.F. Yang, The Effect of Surface Texturing on Reducing the Friction and Wear of Steel under Lubricated Sliding Contact, Appl. Surf. Sci., 2013, 273, p 199–204

T.C. Hu, L.T. Hu, and Q. Ding, Effective Solution for the Tribological Problems of Ti–6Al–4V: Combination of Laser Surface Texturing and Solid Lubricant Film, Surf. Coat. Technol., 2012, 206, p 5060–5066

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51501125), the China Postdoctoral Science Foundation (No. 2016M591415).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, N., Li, D., Zou, J. et al. Tribological Behavior of Electrochemically Etched AISI 316 Stainless Steel with a Textured Surface. J. of Materi Eng and Perform 27, 6616–6628 (2018). https://doi.org/10.1007/s11665-018-3748-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3748-1