Abstract

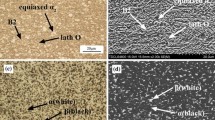

CO2 laser welding of Ti-15V-3Cr-3Al-3Sn to Ti-4.5Al-3V-2Fe-2Mo was conducted in the study. The notched fracture and microstructures of the weld metal (WM) with various post-weld aging treatments were studied. In the as-welded sample, the WM comprised only β phase, which was relatively soft and ductile. Moreover, the phase constituent of the as-welded WM was related to the Al and Mo equivalents and further compared with other welds. The microstructural morphologies and microhardness of the WMs of dissimilar welds exhibited significant changes after post-weld aging at distinct temperatures. Increasing the Al equivalent ([Al]EQ) of the WM caused an increased response to age-hardening during post-weld aging treatments. When the aging temperature was increased from 426 to 593 °C, the α precipitates in the WM grew in size, causing a decrease in hardness, but an improvement in toughness.

Similar content being viewed by others

References

M. Ishikawa, O. Kuboyama, M. Niikura and C. Ouchi, in Microstructure and Mechanical Properties Relationship of β-Rich α-β Titanium Alloy: SP-700, Titanium ‘92 Science and Technology, ed. by F. H. Froes, I. Caplan (TMS, San Diego, June, 1992, 1993), p 141–148

P.N. Comley, in Aerospace Part Production Using SP 700, Superplasticity in Advanced Materials—ICSAM 2000, vol. 357–359, ed. by N. Chandra (Materials Science Forum, Orlando, August 2000, 2001), p 41–46

W. Swale and R. Broughton, in Applying Superplastic Forming Principles to Titanium Sheet Metal Forming Problems, Superplasticity in Advanced Materials—ICSAM 2003, vol. 447–448, ed. by R.I. Todd (Materials Science Forum, Oxford, July 2003, 2004,) p 239–246

P.N. Comley, in Lowering The Heat—The Development of Reduced SPF Temperature Titanium Alloys for Aircraft Production, Superplasticity in Advanced Materials—ICSAM 2003, vol. 447–448, ed. by R.I. Todd (Materials Science Forum, Oxford, July 2003, 2004) p 233–238

Y.H. Lin, S.M. Wu, F.H. Kao, S.H. Wang, J.R. Yang, C.C. Yang, and C.S. Chiou, Microtwin Formation in The α Phase of Duplex Titanium Alloys Affected by Strain Rate, Mater. Sci. Eng. A Struct, 2011, 528(6), p 2271–2276

S.H. Wang, H.H. Lee, C.Y. Chen, J.R. Yang, and C.H. Kao, The Variation of Beta Phase Morphology After Creep for Duplex Titanium Alloys, J. Mater. Sci., 2009, 44(2), p 408–413

A. Ogawa, M. Niikura, C. Ouchi, K. Minikawa, and M. Yamada, Development and Applications of Titanium Alloy SP-700 with High Formability, J. Test. Eval., 1996, 24(2), p 100–109

T. Horiya and T. Kishi, Fracture Toughness of Titanium Alloys, Nippon Steel Tech. Rep., 1994, 62, p 85–91

F. Prima, F. Sun, P. Vermaut, T. Gloriant, D. Mantovani, and P.J. Jacques, High Performance Beta Titanium Alloys as a New Material Perspective for Cardiovascular Applications, Mater. Sci. Forum, 2012, 706–709, p 578–583

R.R. Boyer, Attributes, Characteristics, and Applications of Titanium and Its Alloys, JOM-US, 2010, 62(5), p 21–24

R.R. Boyer and R.D. Briggs, The Use of Beta Titanium Alloys in the Aerospace Industry, J. Mater. Eng. Perform., 2013, 22(10), p 2916–2920

O.M. Ivasishin, P.E. Markovsky, S.L. Semiatin, and C.H. Ward, Aging Response of Coarse- and Fine-Grained β Titanium Alloys, Mater. Sci. Eng. A Struct., 2005, 405(1–2), p 296–305

Y. Kawabe and S. Muneki, Strengthening and Toughening of Titanium-Alloys, ISIJ Int., 1991, 31(8), p 785–791

N.K. Babu and S.G.S. Raman, Influence of Current Pulsing on Microstructure and Mechanical Properties of Ti-6Al-4 V TIG Weldments, Sci. Technol. Weld. Join., 2006, 11(4), p 442–447

J.H. Xiong, S.K. Li, F.Y. Gao, and J.X. Zhang, Microstructure and Mechanical Properties of Ti6321 Alloy Welded Joint by GTAW, Mater. Sci. Eng. A Struct., 2015, 640, p 419–423

B. Mehdi, R. Badji, V. Ji, B. Allili, D. Bradai, F. Deschaux-Beaume, and F. Soulie, Microstructure and Residual Stresses in Ti-6Al-4 V Alloy Pulsed and Unpulsed TIG Welds, J. Mater. Process. Technol., 2016, 231, p 441–448

T.S. Balasubramanian, M. Balakrishnan, V. Balasubramanian, and M.A. Muthu, Manickam, Effect of Welding Processes on Joint Characteristics of Ti-6Al-4 V Alloy, Sci. Technol. Weld. Join., 2011, 16(8), p 702–708

X.L. Gao, L.J. Zhang, J. Liu, and J.X. Zhang, A Comparative Study of Pulsed Nd:YAG Laser Welding and TIG Welding of Thin Ti6Al4 V Titanium Alloy Plate, Mater. Sci. Eng. A Struct., 2013, 559, p 14–21

M. Junaid, M.N. Baig, M. Shamir, F.N. Khan, K. Rehman, and J. Haider, A Comparative Study of Pulsed Laser and Pulsed TIG Welding of Ti-5Al-2.5Sn Titanium Alloy Sheet, J. Mater. Process. Technol., 2017, 242, p 24–38

G. Casalino, Advances in Welding Metal Alloys, Dissimilar Metals and Additively Manufactured Parts, Metals-Basel, 2017, 7(2), p 32. 10.3390/met7020032

J.E. Blackburn, C.M. Allen, P.A. Hilton, L. Li, M.I. Hoque, and A.H. Khan, Modulated Nd:YAG Laser Welding of Ti-6Al-4 V, Sci. Technol. Weld. Join., 2010, 15(5), p 433–439

Jing. Liu, Xiaolong. Gao, and Jianxun. Zhang, Effect of Heat Input on the Tensile Damage Evolution in Pulsed Laser Welded Ti6Al4 V Titanium Sheets, J. Mater. Eng. Perform., 2016, 25(11), p 5109–5124

J. Blackburn, C. Allen, P. Hilton, and L. Li, Nd:YAG Laser Welding of Titanium Alloys Using A Directed Gas Jet, J. Laser. Appl., 2010, 22(2), p 71–78

Dalong. Li, Hu. Shengsun, Junqi. Shen, Hao. Zhang, and Bu. Xianzheng, Microstructure and Mechanical Properties of Laser-Welded Joints of Ti-22Al-25Nb/TA15 Dissimilar Titanium Alloys, J. Mater. Eng. Perform., 2016, 25(5), p 1880–1888

C.T. Hsieh, C.Y. Chu, R.K. Shiue, and L.W. Tsay, The Effect of Post-Weld Heat Treatment on the Notched Tensile Fracture of Ti-6Al-4 V to Ti-6Al-6 V-2Sn Dissimilar Laser Welds, Mater. Des., 2014, 59, p 227–232

C.Y. Chu, C.T. Hsieh, and L.W. Tsay, Microstructure and Notched Tensile Fracture of Ti-6Al-4 V to Ti-4.5Al-3 V-2Fe-2Mo Dissimilar Welds, Mater. Des., 2014, 63, p 14–19

C.T. Hsieh, R.K. Shiue, R.T. Huang, and L.W. Tsay, The Effect of Post-Weld Heat Treatment on the Microstructure and Notched Tensile Fracture of Ti-15 V-3Cr-3Al-3Sn to Ti-6Al-4 V Dissimilar Laser Welds, Mater. Sci. Eng. A Struct., 2016, 653, p 139–146

S.Q. Wang, J.H. Liu, and D.L. Chen, Tensile and Fatigue Properties of Electron Beam Welded Dissimilar Joints between Ti-6Al-4 V and BT9 Titanium Alloys, Mater. Sci. Eng. A Struct., 2013, 584, p 47–56

S.Q. Wang, J.H. Liu, and D.L. Chen, Strain-Controlled Fatigue Properties of Dissimilar Welded Joints between Ti-6Al-4 V and Ti17 Alloys, Mater. Des., 2013, 49, p 716–727

G. Welsch, R. Boyer, and E.W. Collings, Materials Properties Handbook: Titanium Alloys, ASM International, Materials Park, OH, 1994, p 685–692

L.W. Tsay, Y.S. Ding, W.C. Chung, and C. Chen, Notched Tensile Strength of SP-700 Laser Welds, Mater. Lett., 2008, 62(6–7), p 1114–1117

L.W. Tsay, C.X. Lee, and C. Chen, Notched Tensile Strength and Fatigue Crack Growth Behavior of Ti-6Al-6 V-2Sn Laser Welds, Mater. Trans., 2009, 50(7), p 1785–1791

L.W. Tsay, Y.J. Wu, and C. Chen, Notched Tensile and Impact Fracture of Ti-15-3 Laser Welds, Metall. Mater. Trans. A, 2011, 42(12), p 3778–3784

H.C. Lin and L.M. Wang, Improved Mechanical Properties of Ti-15 V-3Cr-3Sn-3Al Alloy by Electron Beam Welding Process Plus Heat Treatments and Its Microstructure Evolution, Mater. Chem. Phys., 2011, 126(3), p 891–897

M. Nakai, M. Niinomi, T. Akahori, K. Hayashi, Y. Itsumi, S. Murakami, H. Oyama, and W. Abe, Microstructural Factors Determining Mechanical Properties of Laser-Welded Ti-4.5Al-2.5Cr-1.2Fe-0.1C Alloy for Use in Next-Generation Aircraft, Mater. Sci. Eng. A Struct., 2012, 550, p 55–65

T. Shariff, X. Cao, R.R. Chromik, J.G. Baradari, P. Wanjara, J. Cuddy, and A. Birur, Laser Welding of Ti-5Al-5 V-5Mo-3Cr, Can. Metall. Q., 2011, 50(3), p 263–272

Y.N. Guo, T. Jung, Y.L. Chiu, H.Y. Li, S. Bray, and P. Bowen, Microstructure and Microhardness of Ti6246 Linear Friction Weld, Mater. Sci. Eng. A Struct., 2013, 562, p 17–24

R.T. Huang, W.L. Huang, R.H. Huang, and L.W. Tsay, Effects of Microstructures on the Notch Tensile Fracture Feature of Heat-Treated Ti-6Al-6 V-2Sn Alloy, Mater. Sci. Eng. A Struct, 2014, 595, p 297–305

Acknowledgments

The funding support of the Ministry of Science and Technology, R. O. C. is acknowledged (Grant number: 101-2221-E019-032-MY3).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsai, YD., Hsieh, CT., Shiue, RK. et al. The Evolution of the Weld Metal Microstructures in Dissimilar Titanium Welds Based on Al and Mo Equivalents. J. of Materi Eng and Perform 26, 6006–6012 (2017). https://doi.org/10.1007/s11665-017-3034-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-3034-7