Abstract

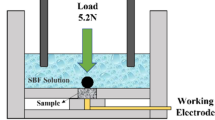

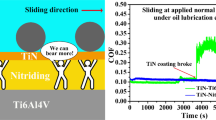

Closed field unbalanced magnetron sputtering was used to deposit diamond-like carbon (Ti-C:H) coatings on Ti6Al4V alloy and gas nitrided Ti6Al4V alloy. Four different specimens were prepared, namely untreated Ti6Al4V alloy (Ti6Al4V), gas nitrided Ti6Al4V alloy (N-Ti6Al4V), Ti-C:H-coated Ti6Al4V alloy (Ti-C:H/Ti6Al4V) and Ti-C:H-coated gas nitrided Ti6Al4V alloy (Ti-C:H/N-Ti6Al4V). The tribological properties of the four specimens were evaluated using a reciprocating wear tester sliding against a Si3N4 ball (point contact mode) and 316L stainless steel cylinder (line contact mode). The wear tests were performed in a 0.89 wt.% NaCl solution. The results showed that the nitriding treatment increased the surface roughness and hardness of the Ti6Al4V alloy and improved the wear resistance as a result. In addition, the Ti-C:H coating also improved the tribological performance of Ti6Al4V. For example, compared to the untreated Ti6Al4V sample, the Ti-C:H coating reduced the wear depth and friction coefficient by 340 times and 10 times, respectively, in the point contact wear mode, and 151 times and 9 times, respectively, in the line contact wear mode. It is thus inferred that diamond-like carbon coatings are of significant benefit in extending the service life of artificial biomedical implants.

Similar content being viewed by others

References

Y.H. Zhu, K.Y. Chiu, and W.M. Tang, Polyethylene Wear and Osteolysis in Total Hip Arthroplasty, J. Orthop. Surg., 2001, 9, p 91–99

S. Pramanik, A.K. Agarwal, and K.N. Rail, Total Hip Joint Replacement and Materials Development, Trends Biomater. Artif. Organs, 2005, 19, p 15–26

A. Unswotih, Recent Developments in the Tribology of Artificial Joints, Tribol. Int., 1995, 28, p 485–495

D. Dowson, A Comparative Study of the Performance of Metallic and Ceramic Femoral Head Components in Total Replacement Hip Joints, Wear, 1995, 190, p 171–183

P. Bizot, L. Banallec, L. Sedel, and R. Nizard, Alumina-on-Alumina Total Hip Prostheses in Patients 40 Years of Age or Younger, Clin. Orthop., 2000, 379, p 68–76

P. Boyer, D. Huten, P. Loriaut, V. Lestrat, C. Jeanrot, and P. Massin, Is Alumina-on-Alumina Ceramic Bearings Total Hip Replacement the Right Choice in Patients Younger than 50 Years of Age? A 7- to 15-Year Follow-Up Study, Orthop. Traumatol. Surg. Res., 2010, 96, p 616–622

M. Pourbaix, Electrochemical Corrosion of Metallic Biomaterials, Biomaterials, 1984, 5, p 122–134

LifeBridge Health Home, Conserve Plus Metal-on-Metal Hip Replacement. http://www.lifebridgehealth.org/RIAO/FDAMetalonMetalStudy.aspx

S.F. Harwin, FACS, Ceramic Hip Replacements & Hip Replacement Surgery. http://drharwin.com/home/

F.R. Marciano, L.F. Bonetti, J.F. Mangolin, N.S. Da-Silva, E.J. Corat, and V.J. Trava-Airoldi, Investigation into the Anti Bacterial Property and Bacterial Adhesion of Diamond-Like Carbon Films, Vacuum, 2011, 85, p 662–666

F.R. Marciano, L.F. Bonetti, L.V. Santos, N.S. Da-Silva, E.J. Corat, and V.J. Trava-Airoldi, Antibacterial Activity of DLC and Ag-DLC Films Produced by PECVD Technique, Diam. Relat. Mater., 2009, 18, p 1010–1014

A. Almaguer-Flores, R. Olivares-Navarrete, A. Lechuga-Bernal, L.A. Ximénez-Fyvie, and S.E. Rodil, Oral Bacterial Adhesion on Amorphous Carbon Films, Diam. Relat. Mater., 2009, 18, p 1179–1185

Y. Ohgoe, K.K. Hirakuri, H. Saitoh, T. Nakahigashi, N. Ohtake, A. Hirata et al., Classification of DLC Films In Terms of Biological Response, Surf. Coat. Technol., 2012, 207, p 350–354

L. Wang, J.F. Su, and X. Nie, Corrosion and Tribological Properties and Impact Fatigue Behaviors of TiN- and DLC-Coated Stainless Steels in a Simulated Body Fluid Environment, Surf. Coat. Technol., 2010, 205, p 1599–1605

J. Wang and M. Liu, Study on the Tribological Properties of Hard Films Deposited on Biomedical NiTi alloy, Mater. Chem. Phys., 2011, 129, p 40–45

L. Randeniya, A. Bendavid, P.L. Martin, J. Cairney, A. Sullivan, S. Webster et al., Thin Film Composites of Nanocrystalline ZrO2 and Diamond-Like Carbon: Synthesis, Structural Properties and Bone Cell Proliferation, Acta Biomater., 2010, 6, p 4154–4160

A.C. Martin, L. Saldana, H. Korhonen, A. Soininen, T.J. Kinnari, E.G. Barrena et al., Interactions of Human Bone Cells with Diamond-Like Carbon Polymer Hybrid Coatings, Acta Biomater., 2010, 6, p 3325–3338

E. Salgueiredo, M. Vila, M.A. Silva, M.A. Lopes, J.D. Santos, F.M. Costa et al., Biocompatibility Evaluation of DLC-Coated Si3N4 Substrates for Biomedical Applications, Diam. Relat. Mater., 2008, 17, p 878–881

T.L. Parker, K.L. Parker, I.R. McColl, D.M. Grant, and J.V. Wood, The Biocompatibility of Low Temperature Diamond-Like Carbon Films: A Transmission Electron Microscopy, Scanning Electron Microscopy and Cytotoxicity Study, Diam. Relat. Mater., 1994, 3, p 1120–1123

R. Hauert, A Review of Modified DLC Coatings for Biological Applications, Diam. Relat. Mater., 2003, 12, p 583–589

A.F. Yetim, A. Celik, and A. Alsaran, Improving Tribological Properties of Ti6Al4V Alloy with Duplex Surface Treatment, Surf. Coat. Technol., 2010, 205, p 320–324

M. Anil, S.F. Ahmed, J.W. Yi, M.W. Moon, K.R. Lee, Y.C. Kim et al., Tribological Performance of Hydrophilic Diamond-Like Carbon Coatings on Ti-6Al-4V in Biological Environment, Diam. Relat. Mater., 2010, 19, p 300–304

E. Arslan, Y. Totik, E.E. Demirci, and I. Efeoglu, Wear and Adhesion Resistance of Duplex Coatings Deposited on Ti6Al4V Alloy Using MAO and CFUBMS, Surf. Coat. Technol., 2013, 214, p 1–7

A.F. Yetima, F. Yildiz, Y. Vangolua, A. Alsarana, and A. Celika, Several Plasma Diffusion Processes for Improving Wear Properties of Ti6Al4V Alloy, Wear, 2009, 267, p 2179–2185

S. Taktak and H. Akbulut, Dry Wear and Friction Behaviour of Plasma Nitrided Ti-6AL-4V Alloy After Explosive Shock Treatment, Tribol. Int., 2007, 40, p 423–432

W.H. Kao, Y.L. Su, and S.H. Yao, Improving Tribological Properties and Machining Performance of a-C Coatings by Doping with Titanium, J. Mater. Eng. Perform., 2006, 15, p 525–534

T. Arai, H. Fujita, and M. Watanable, Evaluation of Adhesion Strength of Thin Hard Coatings, Thin Solid Films, 1987, 154, p 387–401

A.K. Bhattacharya and W.D. Nix, Analysis of Elastic and Plastic Deformation Associated with Indentation Testing of Thin Films on Substrates, Int. J. Solids Struct., 1988, 24, p 1287–1298

Acknowledgment

The authors gratefully acknowledge the financial support provided to this study by the Ministry of Science and Technology of Taiwan under Contract No. MOST 103-2221-E270-002.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kao, W.H., Su, Y.L., Horng, J.H. et al. The Tribological Performance of Surface Treated Ti6A14V as Sliding Against Si3N4 Ball and 316L Stainless Steel Cylinder. J. of Materi Eng and Perform 25, 5209–5219 (2016). https://doi.org/10.1007/s11665-016-2384-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2384-x