Abstract

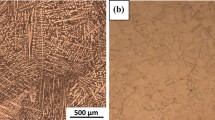

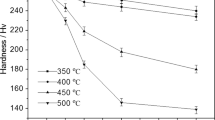

A novel Cu-10Zn-1.5Ni-0.34Si alloy was designed to replace the expensive tin-phosphor bronze in this paper. The alloy had better comprehensive mechanical properties than traditional C5191 alloy. The aged Cu-10Zn-1.5Ni-0.34Si alloy had a hardness of 220 HV, electrical conductivity of 28.5% IACS, tensile strength of 650 MPa, yield strength of 575 MPa and elongation of 13%. Ni2Si precipitates formed during aging, and the crystal orientation relationship between matrix and precipitates was: (001)α//(001)δ, and [110]α//[100]δ. Ductile fracture surface with deep cavities was found in the alloy. Solid solution strengthening, deformation strengthening and precipitation strengthening were found to be core strengthening mechanisms in the alloy.

Similar content being viewed by others

References

Y. Zhang, B.H. Tian, A.A. Volinsky, H.L. Sun, Z.P. Liu, X.H. Chen, and Y. Liu, Microstructure and Precipitate’s Characterization of the Cu-Ni-Si-P Alloy, J. Mater. Eng. Perform., 2016, 25, p 1336–1341

Y. Zhang, P. Liu, B.H. Tian, Y. Liu, R.Q. Li, and Q.Q. Xu, Hot Deformation Behavior and Processing Map of Cu-Ni-Si-P Alloy, Trans. Nonferrous Met. Soc. China, 2013, 23, p 2341–2347

Y. Zhang, A.A. Volinsky, Q.Q. Xu, Z. Chai, B.H. Tian, P. Liu, and H.T. Tran, Deformation Behavior and Microstructure Evolution of the Cu-2Ni-0.5Si-0.15Ag Alloy During Hot Compression, Metall. Mater. Trans. A, 2015, 46, p 5871–5876

Y. Jia, M. Wang, C. Chen, Q. Dong, S. Wang, and Z. Li, Orientation and Diffraction Patterns of δ-Ni2Si Precipitates in Cu-Ni-Si Alloy, J. Alloys Compd., 2013, 557, p 147–151

H. Tsubakino, R. Nozato, and A. Yamamoto, Precipitation Sequence for Simultaneous Continuous and Discontinuous Modes in Cu-Be Binary Alloys, Mater. Sci. Technol., 1993, 9, p 288–294

M. Miyafuji, Shirnonoseki-shi, Copper Alloy with Excellent Stress Relaxation Resistance Property and Production Method Therefor, United States patent US 2003/0047259 A1, 2003

R.M. Hussein and O.I. Abd, Influence of Al and Ti Additions on Microstructure and Mechanical Properties of Leaded Brass Alloys, Indian J. Mater. Sci., 2014, 2014, p 1–5

Q. Lei, Z. Li, C. Dai, J. Wang, X. Chen, J.M. Xie, W.W. Yang, and D.L. Chen, Effect of Aluminum on Microstructure and Property of Cu-Ni-Si Alloys, Mater. Sci. Eng. A, 2013, 572, p 65–74

H. Fujiwara, T. Sato, and A. Kamio, Effect of Alloy Composition on Precipitation Behavior in Cu-Ni-Si Alloys, J. Jpn. Inst. Met., 1998, 62, p 301–309

D.M. Zhao, Q.M. Dong, P. Liu, B.X. Kang, J.L. Huang, and Z.H. Jin, Structure and Strength of the Age Hardened Cu-Ni-Si Alloy, Mater. Chem. Phys., 2003, 79, p 81–86

F. Huang, J. Ma, H. Ning, Y. Cao, and Z. Geng, Precipitation in Cu-Ni-Si-Zn Alloy for Lead Frame, Mater. Lett., 2003, 57, p 2135–2139

ASTM Standard, E384-11, Standard Test Method for Knoop and Vickers Hardness of Materials, ASTM International, West Conshohocken, 2011

S. Nestorović, D. Markovi´c, and I. Markovi´c, Influence of Thermal Cycling Treatment on the Anneal Hardening Effect of Cu-10Zn Alloy, J. Alloys Compd., 2010, 489, p 582–585

M. Bader, G.T. Eldis, and H. Warlimont, The Mechanisms of Anneal Hardening in Cu-Al Alloys, Metall. Trans. A, 1976, 7, p 249–255

S. Nestorović, B. Milicević, and D. Marković, Anneal Hardening Effect in Sintered Copper Alloys, Sci. Sinter., 2002, 34, p 169–174

M.D. Teplitskiy, A.K. Nikolayev, N.I. Revina, and V.M. Rozenberg, The Structure and Properties of Aging Copper-Nickel Based Alloys, Fiz. Metal. Metalloved., 1975, 40, p 1240–1243

P. Virtanen and T. Tiainen, Stress Relaxation Behaviour in Bending of High Strength Copper Alloys in the Cu-Ni-Sn System, Mater. Sci. Eng. A, 1997, 238, p 407–410

F. Li, X. Zhao, X. Li, and Y.H. Jin, Analysis of Valence Electron Structures of Cu-Zn Alloy Solid Solutions, Ordnance Mater. Sci. Eng., 2009, 32, p 23–25 (in chinese)

M. Mabuchi and K. Higashi, Strengthening Mechanism of Mg-Si Alloy, Acta Mater., 1996, 44, p 4611–4618

R.M. Aikin and L. Christodoulou, The Role of Equiaxed Particles on the Yield Stress of Composites, Scr. Metall. Mater., 1991, 25, p 9–14

G. Le Roy, J.D. Embury, G. Edward, and M.F. Ashby, A Model of Ductile Fracture Based on the Nucleation and Growth of Voids, Acta Metal., 1981, 29(8), p 1509–1522

Acknowledgments

The authors are pleased to acknowledge the financial supply supported by the Project supported by the National Natural Science Foundation of China (51271203) and the Project of Innovation-driven Plan in Central South University.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chen, W., Wang, M., Li, Z. et al. A Novel Cu-10Zn-1.5Ni-0.34Si Alloy with Excellent Mechanical Property Through Precipitation Hardening. J. of Materi Eng and Perform 25, 4624–4630 (2016). https://doi.org/10.1007/s11665-016-2354-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2354-3