Abstract

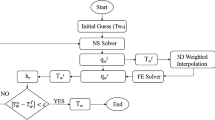

This work is motivated by the frequent occurrence of macro- and microdefects within forged Ti-6Al-4V turbine blades due to the severely nonuniform strain and temperature distributions. To overcome the problem of nonuniformity during the blade forging operation, firstly, a 2D coupled thermo-mechanical finite element approach using the strain-compensated Arrhenius-type constitutive model is employed to simulate the real movements and processing conditions, and its reliability is verified experimentally. Secondly, two evaluation indexes, standard deviation of equivalent plastic strain and standard deviation of temperature, are proposed to evaluate the uniformity characteristics within the forged blade, and the effects of four process parameters including the forging velocity, friction factor, initial workpiece temperature and dwell time on the uniformity of strain and temperature distributions are carefully studied. Finally, the numerically optimized combination of process parameters is validated by the application in a practical process. The parametric study reveals that a reasonable combination of process parameters considering the flow resistance, flow localization and the effects of deformation and friction heating is crucial for the titanium alloy blade forging with uniformity. This work can provide a significant guidance for the design and optimization of blade forging processes.

Similar content being viewed by others

Abbreviations

- A :

-

Material constant of Arrhenius-type constitutive model

- C :

-

Heat capacity

- D :

-

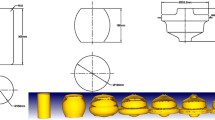

Diameter of preform blade

- E :

-

Young’s modulus

- h :

-

Convection coefficient to environment

- k :

-

Shear yield stress

- K a :

-

Thermal conductivity

- K h :

-

Heat transfer coefficient between workpiece and die

- m :

-

Friction factor

- n :

-

Material constant of Arrhenius-type constitutive model

- \(n^{\prime}\) :

-

Material constant of Arrhenius-type constitutive model

- N r :

-

Ratio of forged blade cross-section area to flash cross-section area

- Q :

-

Activation energy of hot deformation

- R :

-

Universal gas constant

- S a :

-

Cross-section area of final forging blade without flash

- S e :

-

Cross-section area of flash

- S d :

-

Forging stroke of upper die

- T :

-

Temperature

- T d :

-

Initial temperature of die

- T e :

-

Temperature of environment

- T w :

-

Initial temperature of workpiece

- v :

-

Forging velocity

- Z :

-

Modified Zener-Hollomon parameter

- α:

-

Material constant of Arrhenius-type constitutive model

- αt :

-

Thermal expansion coefficient

- β:

-

Material constant of Arrhenius-type constitutive model

- ρ:

-

Density

- τ:

-

Friction stress

- σ:

-

Flow stress

- μ:

-

Poisson’s ratio

- η:

-

Emissivity

- DT:

-

Dwell time before forging

- SDP:

-

Standard deviation of equivalent plastic strain

- SDT:

-

Standard deviation of temperature

References

Y.L. Liu, H. Yang, M. Zhan, and Z.X. Fu, A Study of the Influence of the Friction Conditions on the Forging Process of a Blade with a Tenon, J. Mater. Process. Technol., 2002, 123(1), p 42–46

S.J. Mirahmadi and M. Hamedi, Numerical and Experimental Investigation of Process Parameters in Non-isothermal Forward Extrusion of Ti-6Al-4V, Int. J. Adv. Manuf. Technol., 2014, 75(1–4), p 33–44

H. Yang, M. Wang, L.G. Guo, and Z.C. Sun, 3D Coupled Thermo-Mechanical FE Modeling of Blank Size Effects on the Uniformity of Strain and Temperature Distributions During Hot Rolling of Titanium Alloy Large Rings, Comput. Mater. Sci., 2008, 44(2), p 611–621

L.E. Murr, A.C. Ramirez, S.M. Gaytan, M.I. Lopez, E.Y. Martinez, D.H. Hernandez, and E. Martinez, Microstructure Evolution Associated with Adiabatic Shear Bands and Shear Band Failure in Ballistic Plug Formation in Ti-6Al-4V Targets, Mater. Sci. Eng., A, 2009, 516(1), p 205–216

E. Alabort, D. Putman, and R.C. Reed, Superplasticity in Ti-6Al-4V: Characterisation, Modelling and Applications, Acta Mater., 2015, 95, p 428–442

F. Cao, P. Kumar, M. Koopman, C. Lin, Z.Z. Fang, and K.R. Chandran, Understanding Competing Fatigue Mechanisms in Powder Metallurgy Ti-6Al-4V Alloy: Role of Crack Initiation and Duality of Fatigue Response, Mater. Sci. Eng., A, 2015, 630, p 139–145

N.K. Park, J.T. Yeom, and Y.S. Na, Characterization of Deformation Stability in Hot Forging of Conventional Ti-6Al-4V Using Processing Maps, J. Mater. Process. Technol., 2002, 130, p 540–550

G. Zhou, L. Hua, D.S. Qian, D.F. Shi, and H.X. Li, Effects of Axial Rolls Motions on Radial-Axial Rolling Process for Large-Scale Alloy Steel Ring with 3D Coupled Thermo-Mechanical FEA, Int. J. Mech. Sci., 2012, 59(1), p 1–7

F. Chen, F.C. Ren, J. Chen, Z.S. Cui, and H.G. Ou, Microstructural Modeling and Numerical Simulation of Multi-physical Fields for Martensitic Stainless Steel During Hot Forging Process of Turbine Blade, Int. J. Adv. Manuf. Technol., 2015, doi:10.1007/s00170-015-7368-8

C.L. Hu, H.G. Ou, and Z. Zhao, An Alternative Evaluation Method for Friction Condition in Cold Forging by Ring with Boss Compression Test, J. Mater. Process. Technol., 2015, 224, p 18–25

J.C. Wang, L. Langlois, M. Rafiq, R. Bigot, and H. Lu, Study of the Hot Forging of Weld Cladded Work Pieces Using Upsetting Tests, J. Mater. Process. Technol., 2014, 214, p 365–379

B.S. Kang, N. Kim, and S. Kobayashi, Computer-Aided Preform Design in Forging of an Airfoil Section Blade, Int. J. Mach. Tools Manuf, 1990, 30(1), p 43–52

H. Ou and R. Balendra, Preform Design for Forging of Aerofoil Sections Using FE Simulation, J. Mater. Process. Technol., 1998, 80, p 144–148

M. Zhan, Y.L. Liu, and H. Yang, Influence of the Shape and Position of the Preform in the Precision Forging of a Compressor Blade, J. Mater. Process. Technol., 2002, 120, p 80–83

H. Ou, C.G. Armstrong, and M.A. Price, Die Shape Optimisation in Forging of Aerofoil Sections, J. Mater. Process. Technol., 2003, 132(1), p 21–27

B. Lu, H. Ou, C.G. Armstrong, and A. Rennie, 3D Die Shape Optimisation for Net-Shape Forging of Aerofoil Blades, Mater. Des., 2009, 30(7), p 2490–2500

A. Kocańda, P. Czyżewski, and K.H. Mehdi, Numerical Analysis of Lateral Forces in a Die for Turbine Blade Forging, Arch. Civ. Mech. Eng., 2009, 9(4), p 49–54

S.Y. Luo, D.H. Zhu, D.S. Qian, L. Hua, S.J. Yan, and J.J. Zhang, Effects of Friction Model on Forging Process of Ti-6Al-4V Turbine Blade Considering the Influence of Sliding Velocity, Int. J. Adv. Manuf. Technol., 2015, doi:10.1007/s00170-015-7538-8

Z.M. Hu, J.W. Brooks, and T.A. Dean, Three-Dimensional Finite Element Modelling of Forging of a Titanium Alloy Aerofoil Sectioned Blade, J. Manuf. Sci. Eng., 1999, 121(3), p 366–371

V. Alimirzaloo, M.H. Sadeghi, and F.R. Biglari, Optimization of the Forging of Aerofoil Blade Using the Finite Element Method and Fuzzy-Pareto Based Genetic Algorithm, J. Mech. Sci. Technol., 2012, 26(6), p 1801–1810

Y. Shao, B. Lu, H. Ou, and J. Chen, A New Approach of Preform Design for Forging of 3D Blade Based on Evolutionary Structural Optimization, Struct. Multidiscip. Optim., 2014, 51(1), p 199–211

S.H.R. Torabi, S. Alibabaei, B.B. Bonab, M.H. Sadeghi, and G. Faraji, Design and Optimization of Turbine Blade Preform Forging Using RSM and NSGA II, J. Intell. Manuf., 2015, doi:10.1007/s10845-015-1058-0

J. Cai, K.S. Wang, P. Zhai, F.G. Li, and J. Yang, A Modified Johnson-Cook Constitutive Equation to Predict Hot Deformation Behavior of Ti-6Al-4V Alloy, J. Mater. Eng. Perform., 2015, 24(1), p 32–44

J. Cai, F.G. Li, T.Y. Li, B. Chen, and M. He, Constitutive Equations for Elevated Temperature Flow Stress of Ti-6Al-4V Alloy Considering the Effect of Strain, Mater. Des., 2011, 32(3), p 1144–1151

T. Altan, G. Ngaile, and G. Shen, Cold and Hot Forging: Fundamentals and Applications, ASM International, Materials Park, 2004

C. Lv, L. Zhang, Z.J. Mu, Q.G. Tai, and Q.Y. Zheng, 3D FEM Simulation of the Multi-stage Forging Process of a Gas Turbine Compressor Blade, J. Mater. Process. Technol., 2008, 198(1), p 463–470

K.T. Kim and H.C. Yang, Densification Behavior of Titanium Alloy Powder During Hot Pressing, Mater. Sci. Eng., A, 2001, 313(1), p 46–52

Y.C. Zhu, W.D. Zeng, X. Ma, Q.G. Tai, Z.H. Li, and X.G. Li, Determination of the Friction Factor of Ti-6Al-4V Titanium Alloy in Hot Forging by Means of Ring-Compression Test Using FEM, Tribol. Int., 2011, 44(12), p 2074–2080

R.S. Lee and H.C. Lin, Process Design Based on the Deformation Mechanism for the Non-isothermal Forging of Ti-6Al-4V Alloy, J. Mech. Sci. Technol., 1998, 79(1), p 224–235

Z.C. Sun, H. Yang, and X.F. Guo, FE Analysis on Deformation and Temperature Nonuniformity in Forming of AISI-5140 Triple Valve by Multi-way Loading, J. Mater. Eng. Perform., 2013, 22(2), p 358–365

H.Q. Yu and J.D. Chen, Principles of Metal Forming, China Machine Press, Beijing, 1999 (in Chinese)

X.G. Fan, H. Yang, and P.F. Gao, The Mechanism of Flow Softening in Subtransus Hot Working of Two-Phase Titanium Alloy with Equiaxed Structure, Chin. Sci. Bull., 2014, 59(23), p 2859–2867

S.L. Semiatin and G.D. Lahoti, The Occurrence of Shear Bands in Nonisothermal, Hot Forging of Ti-6AI-2Sn-4Zr-2Mo-0.1Si, Mater. Trans. A, 1983, 14(1), p 105–115

Acknowledgments

The authors would like to gratefully acknowledge the financial support from the National Nature Science Foundation of China (Nos. 51675394, 51375196), the State Key Laboratory of Digital Manufacturing Equipment and Technology (No. DMETKF2016003), the grant from the High-end Talent Leading Program of Hubei Province (No. 2012-86) and the Key R&D Program of Jiangsu Province (No. BE2015005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luo, S., Zhu, D., Hua, L. et al. Effects of Process Parameters on Deformation and Temperature Uniformity of Forged Ti-6Al-4V Turbine Blade. J. of Materi Eng and Perform 25, 4824–4836 (2016). https://doi.org/10.1007/s11665-016-2320-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2320-0