Abstract

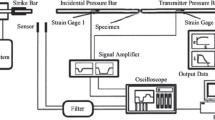

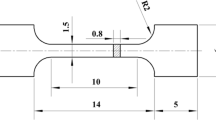

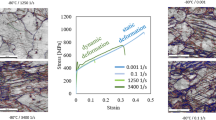

Microstructural evolution and thermal stability of 1050 commercial pure aluminum processed by means of split Hopkinson pressure bar and Instron-3369 mechanical testing machine to an accumulated strain of 3.6 were investigated. The nominal strain rates reached up to 3.0 × 103 and 1 × 10−3/s, respectively. Samples in the deformed state and annealed in the temperature interval 423–523 K for 1 h were characterized by transmission electron microscopy (TEM). TEM observations reveal that the initial coarse grains are refined significantly, and the deformed structures mainly consist of equiaxed subgrains and dislocation cells with a high density of interior dislocation. In addition, the average subgrain/cell sizes of these two kinds of deformed samples are nearly the same. As to recovery behavior, recovered subgrains are observed at 473 (dynamic) versus 523 K (quasi-static), that is to say, recovery is fairly slow in the quasi-static deformed samples. It is therefore to be expected that thermal stability of this dynamic deformed aluminum is weaker than that of the quasi-static compressed one, which is due to the higher density of dislocation and nonequilibrium dislocation configurations produced during dynamic loading.

Similar content being viewed by others

References

N. Tsuji, Y. Ito, Y. Saito, and Y. Minamino, Strength and Ductility of Ultrafine Grained Aluminum and Iron Produced by ARB and Annealing, Scr. Mater., 2002, 47, p 893–899

C.Y. Yu, P.Y. Sun, P.W. Kao, and C.P. Chang, Evolution of Microstructure During Annealing of a Severely Deformed Aluminum, Mater. Sci. Eng. A, 2004, 366, p 310–317

J. May, H.W. Hoppel, and M. Goken, Strain Rate Sensitivity of Ultrafine-Grained Aluminum Processed by Severe Plastic Deformation, Scr. Mater., 2005, 53, p 189–194

N. Hansen, X. Huang, M.G. Moller, and A. Godfrey, Thermal Stability of Aluminum Cold Rolled to Large Strain, J. Mater. Sci., 2008, 43, p 6254–6259

Y. Yang, F. Ma, H.B. Hu, Q.M. Zhang, and X.W. Zhang, Microstructure Evolution of 2195 Al-Li Alloy Subjected to High-Strain-Rate Deformation, Mater. Sci. Eng. A, 2014, 606, p 299–303

Y. Yang, Y. Chen, M. Fei, H. Haibo, Q. Zhang, T. Tang, and X. Zhang, Microstructure Evolution of 1050 Commercial Purity Aluminum Processed by High-Strain-Rate Deformation, J. Mater. Eng. Perform., 2015, 24, p 4307–4312

W.S. Zhao, N.R. Tao, J.Y. Guo, Q.H. Lu, and K. Lu, High Density Nano-Scale Twins in Cu Induced by Dynamic Plastic Deformation, Scr. Mater., 2005, 53, p 745–749

D. Orlov, Y. Todaka, M. Umemoto, and N. Tsuji, Role of Strain Reversal in Grain Refinement by Severe Plastic Deformation, Mater. Sci. Eng. A, 2009, 499, p 427–433

P.N. Rao, D. Singh, and R. Jayaganthan, Mechanical Properties and Microstructural Evolution of Al 6061 Alloy Processed by Multidirectional Forging at Liquid Nitrogen Temperature, Mater. Des., 2014, 56, p 97–104

F. Huang, N.R. Tao, and K. Lu, Effects of Strain Rate and Deformation Temperature on Microstructures and Hardness in Plastically Deformed Pure Aluminum, J. Mater. Sci. Technol., 2011, 27, p 1–7

D.L. Holt, Dislocation Cell Formation in Metals, J. Appl. Phys., 1970, 41, p 3197–3201

I. Sabirov, M.Y. Murashkin, and R.Z. Valiev, Nanostructured Aluminum Alloys Produced by Severe Plastic Deformation: New Horizons in Development, Mater. Sci. Eng. A, 2013, 560, p 1–24

C.C. Koch, Optimization of Strength and Ductility in Nanocrystalline and Ultrafine Grained Metals, Scr. Mater., 2003, 49, p 657–662

M.R. Shankar, S. Chandrasekar, A.H. King, and W.D. Compton, Microstructure and Stability of Nanocrystalline Aluminum 6061 Created by Large Strain Machining, Acta Mater., 2005, 53, p 4781–4793

R. Kapoor, N. Kumar, R.S. Mishra, C.S. Huskamp, and K.K. Sakaran, Influence of Fraction of High Angle Boundaries on the Mechanical Behavior of an Ultrafine Grained Al-Mg Alloy, Mater. Sci. Eng. A, 2010, 527, p 5246–5254

S.S. Hu, L.L. Wang, L. Song, and L. Zhang, Review of the Development of Hopkinson Pressure Bar Technique in China, Explos. Shock Waves, 2014, 34, p 641–657

W.W. Jian, Z.X. Kang, and Y.Y. Li, Microstructural Evolution and Mechanical Property of ME20M Magnesium Alloy Processed by Multidirectional Forging, Chin. J. Nonferr. Met., 2008, 18, p 1005–1011

R.W. Cahn and P. Haasen, Physical Metallurgy, vol. III, 4th ed, North-Holland, Amsterdam, 1996

M.A. Meyers, Dynamic Behavior of Materials, Wiley, New York, 1994, p 405–408

A. Godfrey, W.Q. Cao, N. Hansen, and Q. Liu, Stored Energy, Microstructure, and Flow Stress of Deformed Metals, Metall. Mater. Trans. A, 2005, 36A, p 2371–2378

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Nos. 51274245, 51574290), NSAF (No. U1330126), the Ph.D. Programs Foundation of Ministry of Education of China (No. 20120162130006), the Hunan Provincial Natural Science Foundation of China (No. 14JJ2011) and the Key Project of State Key Laboratory of Explosion Science and Technology (No. KFJJ11-1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Y., Zhang, H. & Chen, Y. Effects of Dynamic Multi-directional Loading on the Microstructural Evolution and Thermal Stability of Pure Aluminum. J. of Materi Eng and Perform 25, 3924–3930 (2016). https://doi.org/10.1007/s11665-016-2233-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2233-y