Abstract

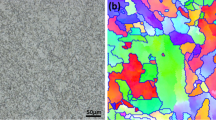

CO2 corrosion, or ‘sweet corrosion,’ is the most prevalent form of attack encountered in oil and gas pipelines. Corrosion of carbon steel in CO2-containing environment is very complex and requires extensive attention. Various mechanisms have been proposed to explain the phenomenon. However, these mechanisms either apply to very specific conditions or have not received widespread recognition or acceptance. To establish a fundamental understanding of CO2 attacks on steel, it is essential to conduct further studies to investigate the formation, composition, microstructure, and characteristics of the surface film induced by carbon dioxide corrosion. In this study, corrosion behavior of API pipeline steel has been assessed in 2 g/l NaCl solution purged with CO2 as the corrosive media. Specimens were immersed in the corrosive solution (open system) for 15, 45, 100, and 185 h. In this study, scanning electron microscopy, x-ray diffraction, and x-ray photoelectron spectroscopy were employed systematically to characterize the composition, microstructure, and formation of the surface film on API X42 steel.

Similar content being viewed by others

References

G.X. Zhao, X. Hong, J.M. Xiang, and Y. Han, Formation Characteristic of CO2 Corrosion Product Layer of P110 Steel Investigated by SEM and Electrochemical Techniques, J. Iron. Steel Res. Int., 2009, 16, p 89

E. Sadeghi Meresht, T. Shahrabi Farahani, and J. Neshati, 2-Butyne-1, 4-Diol as a Novel Corrosion Inhibitor for API, X65 Steel Pipeline in Carbonate/Bicarbonate Solution, Corros. Sci., 2012, 54, p 36

D.G. Li, Y.R. Feng, Z.Q. Bai, and M.S. Zheng, Characteristics of CO2 Corrosion Scale Formed on N80 Steel in Stratum Water with Saturated CO2, Appl. Surf. Sci., 2007, 253, p 8371

B. Wang, M. Du, J. Zhang, and C.J. Gao, Electrochemical and Surface Analysis Studies on Corrosion Inhibition of Q235 Steel by Imidazoline Derivative Against CO2 Corrosion, Corros. Sci., 2011, 53, p 353

S. Guo, L. Xu, L. Zhang, W. Chang, and M. Lu, Corrosion of Alloy Steels Containing 2% Chromium in CO2 Environments, Corros. Sci., 2012, 63, p 246

F.E. Faysal, E.S. Mahdi, and A. Akram, Electrochemical Evaluation of the Corrosion Behaviour of API-X100 Pipeline Steel in Aerated Bicarbonate Solutions, Corros. Sci., 2012, 58, p 181

Y. Xie, L. Xu, C. Gao, W. Chang, and M. Lu, Corrosion Behavior of Novel 3%Cr Pipeline steel in CO2 Top-of-Line Corrosion Environment, Mater. Des., 2012, 36, p 54–57

G.A. Zhang and Y.F. Cheng, Electrochemical Corrosion of X65 Pipe Steel in Oil/Water Emulsion, Corros. Sci., 2009, 51, p 901

E. Dayalan, G. Vani, J.R. Shadley, S.A. Shirazi, and E.F. Rybicki, Modelling CO2 Corrosion of Carbon Steel in Pipe Flow, NACE Corrosion, Houston, Texas, 1995, Paper no. 118

M. Heydari and M. Javidi, Corrosion Inhibition and Adsorption Behaviour of an Amido-imidazoline Derivative on API, 5L X52 Steel in CO2-Saturated Solution and Synergistic Effect of Iodide Ions, Corros. Sci., 2012, 61, p 148

D.R. Lide, Ed., Handbook of Chemistry and Physics, 79th ed., CRS Press, Boca Raton, 1998

M. Ueda and H. Takabe, Effect of Environmental Factor and Microstructure on Morphology of Corrosion Products in CO2 Environments, CORROSION’99, NACE International, Houston, TX, 1999, Paper no. 13

A. Dugstad, L. Lunde, and K. Videm, Parametric Study of CO2 Corrosion of Carbon Steel, CORROSION 94, NACE International, Houston, TX, 1994, Paper no 14

Y. Sun and S. Nesic, A Parametric Study and Modelling on Localized CO2 Corrosion in Horizontal Wet Gas Flow, Corrosion 04, NACE International, Houston, TX, 2004, Paper no. 380

E.W.J. van Hunnik, B.F.M. Pots, and E.L.J.A. Hendriksen, The Formation of Protective FeCO3 Corrosion Product Layers in CO2 Corrosion, CORROSION 96, NACE International, Houston, TX, 1996, Paper no. 6

F.D. de Moraes, S.A. Petrobras, J.R. Shadley, J. Chen, and E.F. Rybicki, Characterization of CO2 Corrosion Product Scales Related to Environmental Conditions, CORROSION 00, NACE International, Houston, TX, 2000, Paper no. 30

S. Nesic and L. Lunde, Carbon Dioxide Corrosion of Carbon Steel in Two-Phase Flow, Corrosion, 1994, 50, p 717

K. Videm, The Influence of Composition of Carbon Steels on Anodic and Cathodic Reaction Rate in CO2 Corrosion, NACE International, Corrosion, Houston, TX, 1998, Paper no 30

K. Videm and A. Dugstad, Corrosion of Carbon Steel in an Aqueous Carbon Dioxide Environment. Part I: Solute Effects, Mater. Perform., 1989, 28, p 63

K. Videm and A. Dugstad, Corrosion of Carbon Steel in an Aqueous Carbon Dioxide Environment. Part II: Film formation, Mater. Perform., 1989, 28, p 46

B. Mishra, S. Al-Hasan, D.L. Olson, and M.M. Salama, Development of a Predictive Model for Activation-Controlled Corrosion of Steel in Solutions Containing Carbon Dioxide, Corrosion, 1997, 53, p 852

C. Waard and D.E. Milliams, Carbonic Acid Corrosion of Steel, Corrosion, 1975, 31, p 177

C. Waard and D.E. Milliams, Predictive Model for CO2 Corrosion Engineering in Wet Natural Gas Pipelines, Corrosion, 1991, 47, p 976

S. Nesic, J. Postlethwaite, and S. Olsen, An Electrochemical Model for Prediction of Corrosion of Mild Steel in Aqueous Carbon Dioxide Solutions, Corrosion, 1996, 52, p 280

A. Neville, X. Hu, and I.M. Ismail, Investigation of Pitting Corrosion and Inhibition in Sweet Conditions, NACE Corrosion, Orlando, Florida, 2013, Paper no 2361

U. Lotz and T. Sydberger, CO2 Corrosion of Carbon Steel and 13Cr Steel in Particle-Laden Fluid, Corrosion, 1998, 44, p 800

F.J.C. Cardoso and M.E. Orazem, Application of a Submerged Impinging Jet to Investigate the Influence of Temperature, Dissolved CO2, and Fluid Velocity on Corrosion of Pipeline Grade Steel in Brine, NACE Corrosion, Houston, TX, 2001, Paper no 01058

J.K. Heuer and J.F. Stubbins, An XPS Characterization of FeCO3 Films from CO2 Corrosion, Corros. Sci., 1999, 41, p 1231

E. Gulbrandsen, J. Kvarekval, and H. Miland, Effect of Oxygen Contamination on the Inhibition of CO2 Corrosion, NACE Corrosion, Houston, TX, 2001, Paper no 01054

R.E. Reed-Hill, Physical Metallurgy Principles, 2nd ed., Litton Educational Publishing International, Mexico, 1979

C.A. Palacios and J.R. Shadley, Characteristics of Corrosion Scales on Steels in a CO2-Saturated NaCl Brine, Corrosion, 1991, 47, p 122

J.L. Crolet, N. Thevenot, and S. Nesic, Role of Conductive Corrosion Products in the Protectiveness of Corrosion Layers, Corrosion, 1998, 54, p 194

A. Dugstad, H. Hemmer, and M. Seiersten, Effect of Steel Microstructure on Corrosion Rate and Protective Iron Carbonate Film Formation, Corrosion, 2001, 57, p 369

R. Jasinski, Corrosion of N80-Type Steel by CO2/Water Mixtures, Corrosion, 1987, 43, p 214

A.K. Pilkey, S.B. Lambert, and A. Plumtree, Stress Corrosion Cracking of X-60 Line Pipe Steel in a Carbonate-Bicarbonate Solution, Corros. Sci., 1995, 51, p 91

C.A. Palacios and J.R. Shadley, CO2 Corrosion of N-80 Steel at 71 C in a Two-Phase Flow System, Corrosion, 1993, 49, p 686

G.X. Zhao, X. Hong, J.M. Xiang, and Y. Han, Formation Characteristic of CO2 Corrosion Product Layer of P110 Steel Investigated by SEM and Electrochemical Techniques, J. Iron. Steel Res. Int., 2009, 16, p 89

D.A. Lopez, W.H. Schreiner, S.R. Sanchez, and S.N. Simison, The Influence of Inhibitors Molecular Structure and Steel Microstructure on Corrosion Layers in CO2 Corrosion An XPS and SEM Characterization, Appl. Surf. Sci., 2004, 236, p 77–97

S.L. Wu, Z.D. Cui, F. He, Z.Q. Bai, S.L. Zhu, and X.J. Yang, Characterization of the Surface Film Formed from Carbon Dioxide Corrosion on N80 Steel, Mater. Lett., 2004, 58, p 1076–1081

ASTM. G31-12a, Standard Guide for Laboratory Immersion Corrosion Testing of Metals. Annual Book of ASTM Standards, Vol 03.02, ASTM International, West Conshohocken, 2013

A. Dugstad, Importance of FeCO3 Supersaturation on the CO2 Corrosion of Carbon Steels, NACE Corrosion, Houston, TX, 1992, Paper no 14

A. Dugstad, Mechanism of Protective Film Formation During CO2 Corrosion of Carbon Steel, NACE CORROSION 98, NACE International, 1998, Paper no 31

J.G. Llongueras, J. Hernandez, A. Munoz, and J.M. Flores, Mechanism of FeCO3 Formation on API X70 Pipeline Steel in Brine Solutions Containing CO2, NACE Corrosion, Houston, Texas, 2005, Paper no 05297

F.F. Eliyan and A. Alfantazi, Effect of Bicarbonate Concentration on Corrosion of High Strength Steel, Corros. Eng. Sci. Technol., 2014, doi:10.1179/1743278214Y.0000000243

J.F. Moulder, W.F. Stickle, P.E. Sobol, and K.D. Bomben, Handbook of X-ray Photoelectron Spectroscopy, Physical Electronics, Inc., Eden Praire, 1995

J.L. Mora-mendoza and S. Turgoose, Fe3C Influence on the Corrosion Rate of Mild Steel in Aqueous CO2 Systems Under Turbulent Flow Conditions, Corros. Sci., 2002, 44, p 1223

S. Al-hasan, B. Mishra, D.L. Olson, and M.M. Salama, Effect of Microstructure on Corrosion of Steels in Aqueous Solution Containing Carbon Dioxide, Corrosion, 1998, 54, p 480

D.W. Shannon, Role of Chemical Components in Geothermal Brine on Corrosion, NACE CORROSION 78, NACE International, Houston, TX, 1978, Paper no 57.

J.K. Heuer and J.F. Stubbins, Microstructure Analysis of Coupons Exposed to Carbon Dioxide Corrosion in Multiphase Flow, Corrosion, 1998, 54, p 556

W.C. Baek, T. Kang, H.J. Sohn, and Y.T. Kho, In Situ Surface Enhanced Raman Spectroscopy Study on the Effect of Dissolved Oxygen on the Corrosion Film on Low Carbon Steel in 0.01 M NaCl Solution, Electrochim. Acta, 2001, 46, p 2321–2325

D.A. Lopez, W.H. Schreiner, S.R. de Sanchez, and S.N. Simison, The Influence of Carbon Steel Microstructure on Corrosion Layers an XPS and SEM Characterization, Appl. Surf. Sci., 2003, 207, p 69

A. Welle, J.D. Liao, K. Kaiser, M. Grunze, U. Mader, and N. Blank, Interactions of N, N′-dimethylaminoethanol with Steel Surfaces in Alkaline and Chlorine Containing Solutions, Appl. Surf. Sci., 1997, 119, p 185

P. Li, J.Y. Lin, K.L. Tan, and J.Y. Lee, Electrochemical Impedance and X-ray Photoelectron Spectroscopic Studies of the Inhibition of Mild Steel Corrosion in Acids by Cyclohexylamine, Electrochim. Acta, 1997, 42, p 605

Y. Gonzalez, M.C. Lafont, N. Pebere, G. Chatainier, J. Roy, and T. Bouissou, A Corrosion Inhibition Study of a Carbon Steel in Neutral Chloride Solutions by Zinc Salt/Phosphonic Acid Association, Corros. Sci., 1995, 37, p 1823

K. Kurosawa, H.L. Li, Y. Ujihira, and K. Nomura, Characterization of Carbonitrided and Oxidized Layers on Low-Carbon Steel by Conversion Electron Mössbauer Spectrometry, X-ray Diffractometry, and X-ray Photoelectron Spectrometry, Corrosion, 1999, 55, p 238

Acknowledgments

This publication was made possible by NPRP Grant # No. 6-027-2-010 from the Qatar National Research Fund (a member of Qatar Foundation). The statements made herein are solely the responsibility of the authors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Islam, M.A., Farhat, Z.N. Characterization of the Corrosion Layer on Pipeline Steel in Sweet Environment. J. of Materi Eng and Perform 24, 3142–3158 (2015). https://doi.org/10.1007/s11665-015-1564-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1564-4