Abstract

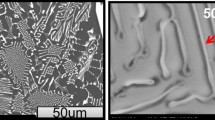

The variation in microstructure, macrosegregation, and solidification behavior during aluminum alloy Direct Chill casting is investigated with respect to geometry. Optical microscopy, energy-dispersive analysis, and differential scanning calorimetry were employed to study the grain size evolution, distribution of alloying elements, and solidification sequence across the cross section of DC cast AA5182 aluminum alloy. The results show that (1) grain size increases from the surface to center of the ingot, corresponding to a decrease in the heat extraction rate; (2) there is a considerable macrosegregation of Mg, Mn, and Cr, with Mg showing negative segregation at the center and positive segregation at the surface, Mn showing negative segregation both at center and surface and positive segregation elsewhere, and Cr showing positive segregation at the center and negative segregation at the surface; (3) the solidus and the reaction temperatures vary as a function of position due to the local chemical composition and cooling rate. These findings, which show the interconnectivity of grain size, segregation, and solidification sequence, are useful in further analysis of the DC casting process and in predicting casting-related defects, specifically hot tear formation.

Similar content being viewed by others

Notes

The nominal composition, Al-3.92 wt.%Mg-0.38 wt.%Mn-0.18 wt.%Cr, was determined by averaging the EDS measurements at individual locations presented in Table 2. The values of Mn and Cr fall within the alloy’s specification. The value for Mg is below what is expected for AA 5182, 4-5 wt.%Mg.

References

D. Carle and B. Gordon, The Suitability of Aluminium as an Alternative Material for Car Bodies, Mater. Des., 1999, 20, p 267–272

S. Das and W. Yin, Trends in the Global Aluminum Fabrication Industry, JOM, 2007, 59, p 83–87

D. Stefanescu, The New Metals Hand Book:, Vol 15, Casting, ASM International, 1988

W.E. Droste, G.U. Grun, W. Schneider, and J.M. Drezet, Thermo-mechanical Modeling to Predict Shrinkage, Shape and Mold Openings for DC-cast Rolling Ingots, Light Metals TMS, 2002, p 703-708

S. Benum, D. Mortensen, H. Fjaer, H. Overlie, and O. Reiso, On the Mechanism of Surface Cracking in DC Cast 7xxx and 6xxx Extrusion Ingot Alloys. Light Metals TMS, 2002, p 967-974

J. Sengupta, S.L. Cockcroft, D.M. Maijer, M.A. Wells, and A. Larouche, On the Development of a Three-dimensional Transient Thermal Model to Predict Ingot Cooling Behavior During the Start-up Phase of the Direct Chill-casting Process for an AA5182 Aluminum Alloy Ingot, Metall. Mater. Trans. B, 2004, 35, p 523–540

A.B. Phillion, S.L. Cockcroft, and P.D. Lee, X-Ray Micro-tomographic Observations of Hot Tear Damage in an Al-Mg Commercial Alloy, Scripta Mater., 2006, 55, p 489–492

A.B. Phillion, S.L. Cockcroft, and P.D. Lee, A New Methodology for Measurement of Semi-solid Constitutive Behavior and its Application to Examination of As-Cast Porosity and Hot Tearing in Aluminum Alloys, Mater. Sci. Eng. A, 2008, 491, p 237–247

J. Drezet and M. Rappaz, Modeling of Ingot Distortions During Direct Chill Casting of Aluminum Alloys, Metal. Mater. Trans. A, 1996, 27, p 3214–3225

A. Williams, T. Croft, and M. Cross, Modeling of Ingot Development During the Start-up Phase of Direct Chill Casting, Metall. Mater. Trans. B, 2003, 34, p 727–734

N. Jamaly, A.B. Phillion, and J.M. Drezet, Stress-Strain Predictions of Semisolid Al-Mg-Mn Alloys During Direct Chill Casting: Effects of Microstructure and Process Variables, Metall. Mater. Trans. B, 2013, 44, p 1287–1295

R. Nadella, D. Eskin, Q. Du, and L. Katgerman, Macrosegregation in Direct-chill Casting of Aluminium Alloys, Prog. Mater. Sci., 2008, 53, p 421–480

D.G. Eskin, R. Nadella, and L. Katgerman, Effect of Different Grain Structures on Centerline Macrosegregation During Direct-Chill Casting, Acta Mater., 2008, 56, p 1358–1365

D.G. Eskin, V.I. Savran, and L. Katgerman, Effects of Melt Temperature and Casting Speed on the Structure and Defect Formation During Direct-Chill Casting of an Al-Cu Alloy, Metall. Mater. Trans. A, 2005, 36, p 1965–1976

A.M. Glenn, S.P. Russo, and P.J.K. Paterson, The Effect of Grain Refining on Macrosegregation and Dendrite Arm Spacing of Direct Chill Cast AA5182, Metall. Mater. Trans. A, 2003, 34, p 1513–1523

H.B. Dong and R. Brooks, Determination of Liquidus Temperature in Al-Si and Al-Si-Mg Alloys Using a Single-Pan Scanning Calorimeter, Mater. Sci. Eng. A, 2005, 413, p 480–484

ASTM E112-10, Standard Test Methods for Determining Average Grain Size, ASTM International, West Conshohocken, PA, 2010

D.E. Newbury and N.W.M. Ritchie, Is Scanning Electron Microscopy/Energy Dispersive X-Ray Spectrometry (SEM/EDS) Quantitative?, Scanning, 2013, 35(3), p 141–168

M.A. Easton and D.H. StJohn, An Analysis of the Relationship Between Grain Size, Solute Content, and the Potency and Number Density of Nucleant Particles, Metall. Mater. Trans. A, 2005, 36, p 1911–1920

D.G. Eskin, Q. Du, D. Ruvalcaba, and L. Katgerman, Experimental Study of Structure Formation in Binary Al–Cu Alloys at Different Cooling Rates, Mater. Sci. Eng. A, 2005, 405, p 1–10

M. Erdegren, M.W. Ullah, T. Carlberg, Simulation of Surface Solidification in Direct-Chill 6xxx Aluminum Billets, IOP Conference Series: Materials Science and Engineering, 2011, 27, p 012013

Suyitno, Hot Tearing and Deformation in Direct Chill Casting of Aluminum Alloys. Ph.D. Thesis, 2005, Delft University of Technology.

H. Nagaumi, Prediction of Porosity Contents and Examination of Porosity Formation in Al-4.4Mg DC Slab, Sci. Technol. Adv. Mater., 2001, 2, p 49–57

D.G. Eskin, Suyitno, and L. Katgerman, Mechanical Properties in the Semi-Solid Sate and Hot Tearing of Aluminum Alloys, Prog. Mater. Sci., 2004, 49, p 629-711

R. Nadella, D.G. Eskin, and L. Katgerman, Effect of Grain Refinement on Structure Evolution, Floating Grains, and Centerline Macrosegregation in Direct-Chill Cast AA2024 Alloy Billets, Metall. Mater. Trans. A, 2008, 39, p 450–461

A. Dons, L. Pedersen, and L. Arnberg, The Origin of ‘Anomalous’ Microsegregation in Al-Si Foundry Alloys—Modelling and Experimental Verification, Mater. Sci. Eng. A, 1999, 271, p 91–94

S. Thompson, S.L. Cockcroft, and M. Wells, Effect of Cooling Rate on Solidification Characteristics of Aluminium Alloy AA5182, Mater. Sci. Technol., 2004, 20, p 497–504

L. Arnberg, L. Backuerud, and G. Chai, Solidification Characteristics of Aluminum Alloys, Volume 3 : Dendrite Coherency. Number v. 3 in Solidification Characteristics of Aluminum Alloys, AFS/Skan Aluminium, 1996

L. Backuerud, G. Chai, and J. Tamminen, Solidification Characteristics of Aluminum Alloys, Volume 2: Foundry Alloys. 3rd ed, AFS Skanaluminium, Stockholm, Sweden, 1990

Acknowledgments

The authors would like to thank the financial support of the Natural Sciences and Engineering Research Council (NSERC) of Canada.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jamaly, N., Haghdadi, N. & Phillion, A.B. Microstructure, Macrosegregation, and Thermal Analysis of Direct Chill Cast AA5182 Aluminum Alloy. J. of Materi Eng and Perform 24, 2067–2073 (2015). https://doi.org/10.1007/s11665-015-1480-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1480-7