Abstract

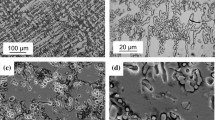

Oxygen-free high-conductivity (OFHC) copper samples are severe plastically deformed by cyclic channel die compression (CCDC) technique at room temperature up to an effective plastic strain of 7.2. Effect of straining on variation in electrical conductivity, evolution of deformation stored energy, and recrystallization onset temperatures are studied. Deformation-induced lattice defects are quantified using three different methodologies including x-ray diffraction profile analysis employing Williamson-Hall technique, stored energy based method, and electrical resistivity-based techniques. Compared to other severe plastic deformation techniques, electrical conductivity degrades marginally from 100.6% to 96.6% IACS after three cycles of CCDC. Decrease in recrystallization onset and peak temperatures is noticed, whereas stored energy increases and saturates at around 0.95-1.1J/g after three cycles of CCDC. Although drop in recrystallization activation energy is observed with the increasing strain, superior thermal stability is revealed, which is attributed to CCDC process mechanics. Low activation energy observed in CCDC-processed OFHC copper is corroborated to synergistic influence of grain boundary characteristics and lattice defects distribution. Estimated defects concentration indicated continuous increase in dislocation density and vacancy with strain. Deformation-induced vacancy concentration is found to be significantly higher than equilibrium vacancy concentration ascribed to hydrostatic stress states experienced during CCDC.

Similar content being viewed by others

References

Y. Estrin and A. Vinogradov, Extreme Grain Refinement by Severe Plastic Deformation: A Wealth of Challenging Science, Acta Mater., 2013, 61(3), p 782–817

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov, Bulk Nanostructured Materials from Severe Plastic Deformation, Prog. Mater Sci., 2000, 45(2), p 103–189

A. Azushima, R. Kopp, A. Korhonen, D.Y. Yang, F. Micari, G.D. Lahoti, P. Groche, J. Yanagimoto, N. Tsuji, A. Rosochowski, and A. Yanagida, A Severe Plastic Deformation (SPD) Processes for Metals, CIRP Ann., 2008, 57(2), p 716–735

V.M. Segal, Materials Processing by Simple Shear, Mater. Sci. Eng. A, 1995, 170(1-2), p 157–164

H.G. Salem and J.S. Lyons, Effect of Equal Channel Angular Extrusion on the Microstructure and Superplasticity of an Al-Li Alloy, J. Mater. Eng. Perform., 2002, 11(4), p 384–391

N. Tsuji, Y. Saito, H. Utsunomiya, and S. Tanigawa, Ultra-Fine Grained Bulk Steel Produced by Accumulative Roll-Bonding (ARB) Process, Scr. Mater., 1999, 40(7), p 95–800

Y. Saito, N. Tsuji, H. Utsunomiya, T. Sakai, and R.G. Hong, Ultra-Fine Grained Bulk Aluminum Produced by Accumulative Roll-Bonding (ARB) Process, Scr. Mater., 1998, 39(9), p 1221–1227

V. Jindal, P.K.P. Rupa, G.K. Mandal, and V.C. Srivastava, Effect of High Temperature Severe Plastic Deformation on Microstructure and Mechanical Properties of IF Steel, J. Mater. Eng. Perform., 2014, 23(6), p 1954–1958

R.Z. Valiev, N.A. Krasilnikov, and N.K. Tsenev, Plastic Deformation of Alloys with Submicron-Grained Structure, Mater. Sci. Eng. A, 1991, 137, p 35–40

Y. Ito and Z. Horita, Microstructural Evolution in Pure Aluminum Processed by High-Pressure Torsion, Mater. Sci. Eng. A, 2009, 503(1-2), p 32–36

Z. Horita and T.G. Langdon, Microstructures and Microhardness of an Aluminum Alloy and Pure Copper After Processing by High-Pressure Torsion, Mater. Sci. Eng. A, 2005, 410-411, p 422–425

G.A. Salishchev, R.M. Galeyev, S.P. Malysheva, and M.M. Myshlyaev, Structure and Density of Submicrocrystalline Titanium Produced by Severe Plastic Deformation, Nanostruct. Mater., 1999, 11(3), p 407–414

N.P. Gurao, P. Kumar, A. Sarkar, H.-G. Brokemeier, and S. Suwas, Simulation of Deformation Texture During Multi Axial Forging of Interstitial Free Steel, J. Mater. Eng. Perform., 2013, 22(4), p 1004–1009

G.A. Salishchev, S. Yu, Mironov, and S.V. Zherebtsov, Mechanism of Submicrocrystalline Structure Formation in Titanium and Two Phase Titanium Alloy During Warm Severe Processing, Rev. Adv. Mater. Sci., 2006, 11(2), p 152–158

S.V. Zherebtsov, G.A. Salishchev, R.M. Galeyev, O.R. Valiakhmetov, S. Mironov Yu, and S.L. Semiatin, Production of Submicrocrystalline Structure in Large-scale Ti-6Al-4V Billet by Warm Severe Deformation Processing, Scr. Mater., 2004, 51(12), p 1147–1151

A.K.Ghosh, Method for Producing a Fine-Grain Aluminium Alloy Using Three Axis Deformation, US Patent 4,721,537, 1988

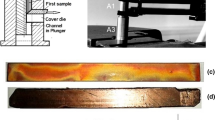

A. Kundu, R. Kapoor, R. Tewari, and J.K. Chakravartty, Severe Plastic Deformation of Copper Using Multiple Compression in a Channel Die, Scr. Mater., 2008, 58(3), p 235–238

A.K. Parimi, P.S. Robi, and S.K. Dwivedy, Severe Plastic Deformation of Copper and Al-Cu Alloy Using Multiple Channel Die Compression, Mater. Des., 2011, 32(4), p 1948–1956

R. Kapoor, A. Sarkar, R. Yogi, S.K. Shekhawat, I. Samajdar, and J.K. Chakravartty, Softening of Al During Multi-axial Forging in a Channel Die, Mater. Sci. Eng. A, 2013, 560, p p404–412

S.H. Ahn, Y.B. Chun, S.H. Yu, K.H. Kim, and S.K. Hwang, Microstructural Refinement and Deformation Mode of Ti Under Cryogenic Channel Die Compression, Mater. Sci. Eng. A, 2010, 528(1), p 165–171

E. Schafler, G. Steiner, E. Korznikov, M. Kerber, and M.J. Zehetbauer, Lattice Defect Investigation of ECAP-Cu by Means of x-ray Line Profile Analysis, Calorimetry and Electrical Resistometry, Mater. Sci. Eng. A, 2005, 410-411, p 169–173

W.Q. Cao, C.F. Gu, E.V. Pereloma, and C.H.J. Davies, Stored Energy, Vacancies and Thermal Stability of Ultra-Fine Grained Copper, Mater. Sci. Eng. A, 2008, 492(1-2), p 74–79

N. Gao, M.J. Starink, and T.G. Langdon, Using Differential Scanning Calorimetry as an Analytical Tool for Ultrafine Grained Materials Processed by Severe Plastic Deformation, Mater. Sci. Technol., 2009, 25(6), p 687–698

H. Jiang, Y.T. Zhu, D.P. Butt, I.V. Alexandrov, and T.C. Lowe, Microstructural Evolution, Microhardness and Thermal Stability of HPT-Processed Cu, Mater. Sci. Eng. A, 2000, 290(1-2), p 128–138

D. Setman, M.B. Kerber, E. Schafler, and M.J. Zehetbauer, Activation Enthalpies of Deformation-Induced Lattice Defects in Severe Plastic Deformation Nanometals Measured by Differential Scanning Calorimetry, Metall. Mater. Trans. A, 2010, 41(4), p 810–815

N. Takata, K. Yamada, K. Ikeda, F. Yoshida, H. Nakashima, and N. Tsuji, Annealing Behaviour and Recrystallized Texture in ARB Processed Copper, Mater. Sci. Forum, 2006, 503-504, p 919–924

F. Khodabakhshi and M. Kazeminezhad, The Effect of Constrained Groove Pressing on Grain Size, Dislocation Density and Electrical Resistivity of Low Carbon Steel, Mater. Des., 2011, 32(6), p p3280–p3286

F. Khodabakhshi and M. Kazeminezhad, Differential Scanning Calorimetry Study of Constrained Groove Pressed Low Carbon Steel: Recovery, Recrystallization and Ferrite to Austenite Phase Transformation, Mater. Sci. Technol., 2014, 30(7), p 765–773

H.E. Kissinger, Reaction Kinetics in Differential Thermal Analysis, Anal. Chem., 1957, 29(11), p 1702–1706

G.K. Williamson and W.H. Hall, X-ray Line Broadening from Filed Aluminium and Wolfram, Acta Metall., 1953, 1(1), p 22–31

Z. Zhang, F. Zhou, and E.J. Lavernia, On the Analysis of Grain Size in Bulk Nanocrystalline Materials by X-ray Diffraction, Metall. Mater. Trans. A, 2003, 34(6), p 1349–1355

N. Rangaraju, T. Raghuram, B. Vamsi Krishna, K. Prasad Rao, and P. Venugopal, Effect of Cryo-Rolling and Annealing on Microstructure and Properties of Commercially Pure Aluminium, Mater. Sci. Eng. A, 2005, 398(1-2), p 246–251

W.D. Casllister, Jr., Materials Science and Engineering: An Introduction, Wiley, Singapore, 1994

O.F. Higuera-Cobos and J.M. Cabrera, Mechanical, Microstructural and Electrical Evolution of Commercially Pure Copper Processed by Equal Channel Angular Extrusion, Mater. Sci. Eng. A, 2013, 571, p 103–114

S.A. Hosseini and H.D. Manesh, High-Strength, High-Conductivity Ultra-Fine Grains Commercial Pure Copper Produced by ARB Process, Mater. Des., 2009, 30(8), p 2911–2918

A. Habibi, M. Ketabchi, and M. Eskandarzadeh, Nano-Grained Pure Copper with High-Strength and High-Conductivity Produced by Equal Channel Angular Rolling Process, J. Mater. Process. Technol., 2011, 211(6), p 1085–1090

N. Lugo, N. Llorca, J.J. Suñol, and J.M. Cabrera, Thermal Stability of Ultrafine Grains Size of Pure Copper Obtained by Equal-Channel Angular Pressing, J. Mater. Sci., 2010, 45(9), p 2264–2273

J. Gubicza, S.V. Dobatkin, E. Khosravi, A.A. Kuznetsov, and J.L. Labar, Microstructural Stability of Cu Processed by Different Routes of Severe Plastic Deformation, Mater. Sci. Eng. A, 2011, 528(3), p 1828–1832

A. Mishra, V. Richard, F. Gregori, R.J. Asaro, and M.A. Meyers, Microstructural Evolution in Copper Processed by Severe Plastic Deformation, Mater. Sci. Eng. A, 2005, 410-411, p 290–298

X. Molodova, G. Gottstein, M. Winning, and R.J. Hellmig, Thermal Stability of ECAP Processed Pure Copper, Mater. Sci. Eng. A, 2007, 460-461, p 204–213

Y. Amouyal, S.V. Divinski, L. Klinger, and E. Rabkin, Grain Boundary Diffusion and Recrystallization in Ultrafine Grain Copper Produced by Equal Channel Angular Pressing, Acta Mater., 2008, 56(19), p 5500–5513

W. Blum, Y.J. Li, and K. Durst, Stability of Ultrafine Grained Cu to Subgrain Coarsening and Recrystallization in Annealing and Deformation at Elevated Temperatures, Acta Mater., 2009, 57(17), p 5207–5217

R. Viswanathan and C.L. Bauer, Kinetics of Grain Boundary Migration in Copper Bi-Crystals with [001] Rotation Axis, Acta Metall., 1973, 21(8), p 1099–1109

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed., Pergamon, Oxford, 2004

A. Takayama, X. Yang, H. Miura, and T. Sakai, Continuous Static Recrystallization in Ultrafine-Grained Copper Processed by Multi-directional Forging, Mater. Sci. Eng. A, 2008, 478(1-2), p 221–228

J. Wang, Y. Iwahashi, Z. Horita, M. Furukawa, M. Nemoto, R.Z. Valiev, and T.G. Langdon, An Investigation of Microstructural Stability in Al-Mg Alloy with Sub Micrometer Grain Size, Acta Mater., 1996, 44(7), p 2973–2982

M.J. Zehetbauer, E. Schafler, and T. Ungar, Vacancies in Plastically Deformed Copper, Z. Metall., 2005, 96(9), p 1044–1048

D. Setman, E. Schafler, E. Korznikova, and M.J. Zehetbauer, The Presence and Nature of Vacancy Type Defects in Nanometals Detained by Severe Plastic Deformation, Mater. Sci. Eng. A, 2008, 493(1-2), p 116–122

J. Gubicza, S.V. Dobatkin, and E. Khosravi, Reduction of Vacancy Concentration During Storage of Severely Deformed Cu, Mater. Sci. Eng. A, 2010, 527(21-22), p 6102–6104

C. Saldana, A.H. King, and S. Chandrasekar, Thermal Stability and Strength of Deformation Microstructures in Pure Copper, Acta Mater., 2012, 60(10), p p4107–p4116

G.I. Taylor, The Mechanism of Plastic Deformation of Crystals. Part I: Theoretical, Proc. R. Soc., 1934, 145(855), p 362–387

S.S. Satheesh Kumar and T. Raghu, Tensile Behaviour and Strain Hardening Characteristics of Constrained Groove Pressed Nickel Sheets, Mater. Des., 2011, 32(8-9), p 4650–4657

Z.S. Basinski and J.S. Dugdale, Electrical Resistivity Due to Dislocations in Highly Purified Copper, Phy. Rev. B, 1985, 32(4), p 2149–2155

A. Rohatgi and K.S. Vecchio, The Variation of Dislocation Density as a Function of the Stacking Fault Energy in Shock-Deformed FCC Materials, Mater. Sci. Eng. A, 2002, 328(1-2), p 256–266

Y.H. Zhao, Z. Horita, T.G. Langdon, and Y.T. Zhu, Evolution of Defect Structures During Cold Rolling of Ultrafine-Grained Cu and Cu-Zn Alloys-Influence of Stacking Fault Energy, Mater. Sci. Eng. A, 2008, 474(1-2), p 342–347

Acknowledgments

Authors thank Dr. Amol A Gokhale, Director, Defence Metallurgical Research Laboratory (DMRL) for permitting us to publish this work. The authors also acknowledge the assistance rendered by Advanced Magnetics Group (AMG) for performing DSC experiments. Authors wish to thank Dr. Pinaki P Bhattacharjee, Head, Dept. of Material Science and Metallurgical Engineering, IIT, Hyderabad for providing access to EBSD characterization. Authors also thank Mr. Akkisetty Bhaskar and Mr. K Basant Kumar, Research Scholars, IIT Hyderabad for helping in carrying out x-ray diffraction experiments.The authors acknowledge the funding provided by Defence Research and Development Organization (DRDO).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Satheesh Kumar, S.S., Raghu, T. Electrical Conductivity, Thermal Stability, and Lattice Defect Evolution During Cyclic Channel Die Compression of OFHC Copper. J. of Materi Eng and Perform 24, 726–736 (2015). https://doi.org/10.1007/s11665-014-1359-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1359-z