Abstract

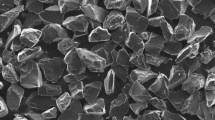

Fabrication and processing of 99.7% purity aluminum powder reinforced with 0, 5, 10% volume fractions NiAl intermetallic metal matrix composites were conducted. The mechanically alloyed nanostructured NiAl was mixed by both regular and high energy ball milling techniques. Powders of NiAl employed for reinforcement were milled for 18 and 31 h, and therefore denoted as NiAl18 and NiAl31, respectively. The mixed powders were consolidated via a combination of cold pressing followed by hot extrusion at 480 °C for 1 h at a reduction ratio 4:1. Hardness, tensile properties, and fracture behavior of the extruded composite powders were evaluated. Structural evolution of the milled composite powders was investigated before and after extrusion using optical microscopy, field emission scanning, and transmission electron microscopy. In addition, particle type identification was carried out via energy dispersive x-ray analysis. Introducing NiAl31 (0.8 µm) enhanced the mechanical properties of the composites compared to NiAl18 (1.0 µm). Moreover, powders milling enhanced the tensile properties post hot extrusion compared to the mixed conditions due to the enhanced reinforcement distribution and bonding with the Al matrices. Hot extruded milled composite powders of Al reinforced with 10% NiAl31 produced nanostructured high-angle grain boundary structure <200 nm.

Similar content being viewed by others

References

A. Prabhu, C. Suryanarayana, L. An, and R. Vaidyanathan, Synthesis and Characterization of High Volume Fraction Al-Al2O3 Nanocomposite Powders by High-Energy Milling, Mater. Sci. Eng., 2006, A425, p 192–200

G. Fu, L. Jiang, J. Liu, and Y. Wang, Fabrication and Properties of Al Matrix Composites Strengthened by In Situ Alumina Particulates, J. Univ. Sci. Techn. Beijing, 2006, 13, p 263

M. Nofar, H.R. Madaah Hosseini, and N. Kolagar-Daroonkolaie, Fabrication of High Wear Resistant Al_Al3Ti Metal Matrix Composite by In Situ Hot Press Method, Mater. Des., 2009, 30, p 280–286

K.B. Lee, H.S. Sim, S.W. Heo, H.R. Yoo, S.Y Cho, and H. Kwon, Tensile Properties and Microstructures of Al Composite Reinforced with BN Particles, Composites, 2002, 33, p 709–715

T.W. Clyne and P.T. Withers, An introduction to Metal Matrix Composites, Cambridge University Press, 1993

S.K. Thakur and M. Gupta, Improving Mechanical Performance of Al by Using Ti as Reinforcement, Composites, 2007, 38, p 1010–1018

Q. Zhang, G. Wu, G. Chen, L. Jiang, and B. Luan, The Thermal Expansion and Mechanical Properties of High Reinforcement Content SiCp Al Composites Fabricated by Squeeze Casting Technology, Composites, 2003, 34, p 1023–1027

P. Yu, Z. Mei, and S. Tjong, Structure, Thermal and Mechanical Properties of In Situ Al-Based Metal Matrix Composite Reinforced with Al2O3 and TiC Submicron Particles, Mater. Chem. Phys., 2005, 93, p 109–116

Z. Huang, B. Yang, H. Cui, and J. Zhang, Study on the Fabrication of Al Matrix Composites Strengthened by Combined In Situ Alumina Particle and In Situ Alloying Elements, Mater. Sci. Eng., 2003, A351, p 15–22

M.H. Enayati, F. Karimzadeh, and S.Z. Anvari, Synthesis of Nanocrystalline NiAl by Mechanical Alloying, J. Mater. Process. Technol., 2008, 200, p 312–315

M.A. Munoz-Morris, J.I. Rexach, and M. Lieblich, Comparative Study of Al-TiAl Composites with Different Intermetallic Volume Fractions and Particle Sizes, Intermetallics, 2005, 13, p 141–149

J.B. Forgagnolo, E.M.J.A. Pallone, D.R. Martin, C.S. Kiminami, C. Bolfarini, and W.J. Botta, Processing of Al Matrix Composites Reinforced with Al-Ni Compounds and Al2O3 by Reactive Milling and Reactive Sintering, J. Alloy. Compd., 2009, 471, p 448–452

D. Kalinski, M. Chmielewski, K. Pietrzak, and K. Choregiewicz, An Influence of Mechanical Mixing and Hot—Pressing on Properties of NiAl/Al2O3, Arch. Metall. Mater., 2012, 57(3), p 695–702

C. Lin, S. Hong, and P. Lee, Formation of NiAl-Al2O3 Intermetallic-Matrix Composite Powders by Mechanical Alloying Technique, Intermetallics, 2000, 8, p 1043–1048

I. Baker and E.P. George, Encyclopedia of Materials: Science and Technology, p 4225–4232

M. Krasnowski, A. Antolak, and T. Kulik, Nanocrystalline Ni3Al Alloy Produced By Mechanical Alloying Of Nickel Aluminides and Hot-Pressing Consolidation, J. Alloys Compd., 2007, 434-435, p 344–347

J. Joardar, S.K. Pabi, and B.S. Murty, Milling Criteria for the Synthesis of Nanocrystalline Nial by Mechanical Alloying, J. Alloy. Compd., 2007, 429, p 204–210

M.M. Moshksar and M. Mirzaee, Formation of NiAl Intermetallic by Gradual and Explosive Exothermic Reaction Mechanism During Ball Milling, Intermetallics, 2004, 12, p 1361–1366

M. Ragab and H.G. Salem, Effect of Milling Energy on the Structural Evolution and Stability of Nanostructured Al-5.7 wt.% Ni Mechanically Alloyed Eutectic Alloy, J. Powder Technol., 2012, 222, p 108–116

M.H. Enayati and M. Salehi, An Investigation of the Use of Ni3Al Intermetallic Compound for Fabrication of Matrix Composites, Esteghlal, 2007, 25(2), p 183–190

T.P.D. Rajan, R.M. Pillai, and B.C. Pai, Functionally Graded Al-Al3Ni In Situ Intermetallic Composites: Fabrication and Microstructural Characterization, J. Alloy. Compd., 2008, 453, p L4–L7

G.K. Williamson and W.H. Hall, X-ray Line Broadening from Filed Aluminium and Wolfram, Acta Metall., 1953, 1, p 1–22

B.D. Cullity and S.R. Stock, Elements of X-Ray Diffraction, 3rd ed., Prentice-Hall Inc., Upper Saddle River, 2001, p 167–171

ASTM, Compilation of ASTM Standard Definitions, 5th ed., American Society for Testing and Materials, Philadelphia, 1982

H.G. Salem and A.A. Sadek, Fabrication of High Performance PM Nanocrystalline Bulk AA2124, J. Mater. Eng. Perform., 2010, 19(3), p 356–367

Estrada Guel, Graphite Nanoparticle Dispersion in 7075 Aluminum Alloy by Means of Mechanical Alloying, J. Alloy. Compd., 2009, 483(1-2), p 173–177

H.G. Salem, S. El-Eskandarany, A. Kandil, and H. Abdel Fattah, Bulk Behavior of Ball Milled AA2124 Nanostructured Powders Reinforced With TiC, J. Nanomater., 2009, 2009, 479185. doi:10.1155/2009/479185

S.S. Nayak, Al-(L12) Al3Ti Nanocomposite Prepared Mechanical Alloying, J. Alloys Compd., 2009, 492(1-2), p 128–133

T.H. Courtney, Mechanical Behavior of Materials, Mc Graw-Hill, New York, 1990

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abd Elhamid, M., Emara, M.M. & Salem, H.G. Influence of Mixing Technique on the Mechanical Properties and Structural Evolution of Al-NiAl Composites. J. of Materi Eng and Perform 23, 3425–3435 (2014). https://doi.org/10.1007/s11665-014-1138-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1138-x