Abstract

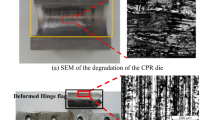

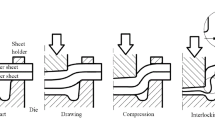

During hot working processes, working tools are subjected to severe conditions. Wear is one of the major life limiting factors of the hot working tools. The identification and understanding of the wear mechanism are extremely important for solving problems related to the hot working process. The ultimate aim of this paper is to assess some wear mechanisms of the tool steel used in hot drawing. The tribological tests were performed on high temperature pin-on-disc tribometer with an open-sliding contact for a simulation of hot-drawing process with a refreshed contact surface. The pin material was X40 CrMoV5 steel and the disc material was Fe 360B steel. Experiments were carried out for different disc temperatures ranging from room temperature to 800°C, a constant sliding speed of 50 rev/min and a constant normal load of 70 N. The evolution surface damage and oxides tribolayers have been investigated by SEM and EDS. The results have shown that an increase in test temperature facilitates the generation of oxide and assists in the compaction of the debris, thus producing a wear protective layer, and therefore, a reduction in friction coefficient.

Similar content being viewed by others

References

A. Pauschitz, M. Roy, and F. Franek, Mechanism of Sliding Wear of Metals and Alloys at Elevated Temperatures, Tribol. Int., 2008, 41, p 584–602

J.H. Beynon, Tribology of Hot Metal Forming, Tribol. Int., 1998, 31, p 73–77

S. Pierzgalski and Q. Luo, Studies of High Temperature Sliding Wear of Metallic Dissimilar Interfaces, Tribol. Int., 2006, 38, p 812–823

P. Muñoz-Escalona, N. Díaz, and Z. Cassier, Prediction of Tool Wear Mechanisms in Face Milling AISI, 1045 Steel, J. Mater. Eng. Perform., 2012, 21, p 797–808

O. Barrau, C. Boher, R. Gras, and F. Rezaï-Aria, Analysis of the Friction and Wear Behaviour of Hot Work Tool Steel for Forging, Wear, 2003, 255, p 1444–1454

C. Vergne, C. Boher, C. Levaillant, and R. Gras, Analysis of the Friction and Wear Behavior of Hot Work Tool Scale: Application to the Hot Rolling Process, Wear, 2001, 250, p 322–333

P.J. Blau, Elevated-Temperature Tribology of Metallic Materials, Tribol. Int., 2010, 43, p 1203–1208

J. Zhi, Z. Jie, J. Jin-jin, H. Liang, and Y. Hai, The Effect of Temperature Condition on Material Deformation and Die Wear, J. Mater. Eng. Perform., 2013, 22, p 2019–2028

Y. Chang and F. Wei, Review High Temperature Oxidation of Low Alloy Steels, J. Mater. Sci., 1989, 24, p 14–22

F.H. Sttot, The Role of Oxidation in the Wear of Alloys, Tribol. Int., 1998, 31, p 61–71

J. Jiang, F.H. Stott, and M.M. Stack, A Generic Model for Dry Sliding Wear of Metals at Elevated Temperatures, Wear, 2004, 256, p 973–985

S. Ilo, A. Tomala, and E. Badisch, Oxidative Wear Kinetics in Unlubricated Steel Sliding Contact, Tribol. Int., 2011, 44, p 1208–1215

M. Marzouki, C. Kowandy, and C. Richard, Experimental Simulation of Tool/Product Interface During Hot Drawing, Wear, 2007, 262, p 235–241

Z. Baccouch, R. Mnif, R. Elleuch, and C. Richard, Analysis of Friction, Wear and Oxidation Behaviour of X40CrMoV5/Fe360B Steel Couple in an Open-Sliding Contact, J. Eng. Tribol., 2014, 228, p 276–287

M. Nakamuraa, K. Hirao, Y. Yamauchi, and S. Kanzaki, Tribological Behaviour of Unidirectionally Aligned Silicon Nitride Against Steel, Wear, 2002, 25, p 484–490

H. Kong, E. Yoon, and O. Kwon, Self-formation of protective oxide films at dry sliding mild steel surfaces under a medium vacuum, Wear, 1996, 181–183, p 325–333

C. Vergne, C. Boher, R. Gras, and C. Levaillant, Influence of Oxides on Friction in Hot Rolling: Experimental Investigations and Tribological Modeling, Wear, 2006, 260, p p957–p975

O. Barreau, Etude du frottement et de l’usure d’acier a` outils de travail à chaud. Thèse à ` l’Institut NationalPolytechnique de Toulouse, 14 Décembre 2004

I.A. Inman, S. Datta, H.L. Du, J.S. Burnell-Gray, and Q. Luo, Microscopy of Glazed Layers Formed During High Temperature Sliding Wear at 750°C, Wear, 2003, 254, p 461–467

G.A. Fontalvo and C. Mitterer, The Effects of Oxide Forming Alloying Elements on the High Temperature Wear of a Hot Work Steel, Wear, 2005, 258, p 1491–1499

O. Joos, C. Boher, and C. Vergne, Assessment of Oxide Scales Influences on Wear Damage of HSM Work Rolls, Wear, 2007, 263, p 198–206

P. Munther and J.G. Lenard, The Effects of Scaling on Interfacial Friction in Hot Rolling of Steels, J. Mater. Process. Technol., 1999, 88, p 105–113

S.Q. Wang, M.X. Wei, and Y.T. Zhao, Effects of the Tribo-oxide and Matrix on Dry Sliding Wear Characteristics and Mechanisms of a Cast Steel, Wear, 2010, 269, p 424–434

P. Lepesant, C. Boher, Y. Berthier, and F. Rezai-Aria, A Phenomenological Model of the Third Body Particles Circulation in a High Temperature Contact, Wear, 2013, 298–299, p 66–79

Acknowledgments

The authors are grateful to SOPAL Society (Tunisia). Special thanks are due to its manager for all valuable help with specimen preparation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mnif, R., Baccouch, Z., Elleuch, R. et al. Investigations of High Temperature Wear Mechanisms for Tool Steel Under Open-Sliding Contact. J. of Materi Eng and Perform 23, 2864–2870 (2014). https://doi.org/10.1007/s11665-014-1082-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1082-9