Abstract

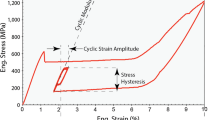

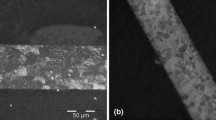

Nitinol medical device implants made from a laser cut tubing process (i.e., stents, valve structures, etc.) frequently require a fatigue durability assessment, which necessitates determining the material fatigue properties. Towards the goal of determining the strain-based endurance limit of medical grade superelastic Nitinol tubing, a coupon was designed and evaluated via FEA using Abaqus software, produced via laser cutting, shape setting, and electro-polishing processes, and then fatigue tested to 10 million cycles. FEA was used to determine the strain versus alternating displacement amplitude for the coupon. Error due to dimensional tolerances was determined. The coupons were then fatigue tested in a 37 °C temperature deionized water bath at alternating strain levels ranging from 0.75 to 4.0% at zero mean strain. Sample replication was greater than 90%, and the median alternating strain fatigue limit was determined via two methods. Confidence and reliability with maximum likelihood statistics are used to present a strain-based endurance limit for the material. The results seem to differ from previous published values.

Similar content being viewed by others

References

AAMI, ANSI/AAMI/ISO 5840:2005/(R)2010, Cardiovascular Implants-Cardiovascular Prostheses, Association for the Advancement of Medical Instrumentation, Arlington, VA, 2010

A.R. Pelton, X.-Y. Gong, and T. Duerig, Fatigue Testing of Diamond Shaped Specimens, SMST-2003: Proceedings of the International Conference on Shape Memory and Superelastic Technologies, Pacific Grove, CA, 2003

ASTM, STP588 Manual on Statistical Planning and Analysis for Fatigue Experiments, ASTM International, Philadelphia, 1975

S. Suresh, Fatigue of Materials, Cambridge University Press, Cambridge, 1998

S.W. Robertson, J. Stankiesicz, X.Y. Gong, and R.O. Ritchie, Cyclic Fatigue of Nitinol, ASM International SMST 2004 Conference Proceedings, 2004

G. Siekmeyer, M. Hientzsch, U. Bayer, and A. Schuessler, The Fatigue Behaviour of Different Nitinol Stent Tubes Characterized by Micro Dog-Bone Testing, ASM Conference, Palm Desert, CA, 2007

A. Wick, X.Y. Gong, J. Fino, J. Sheriff, and A.R. Pelton, Bending Fatigue Characteristics of Nitinol, ASM International—Proceedings of SMST-2004, 2004

ASTM, ASTM E739-10 Standard Practice for Statistical Analysis of Linearized Stress Life and Strain Life Fatigue Data, ASTM International, West Conshohocken, PA, 2010

Acknowledgments

Thank you to DC Devices, Inc. for supporting this work, BDC Labs, Inc. for the fatigue fixture and machine, and LaserAge Technology Corporation for coupon manufacture.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the International Conference on Shape Memory and Superelastic Technologies 2013, held May 20-24, 2013, in Prague, Czech Republic, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Forcucci, S.J. Laser Cut Nitinol Tubing Fatigue Coupon: Design, Testing, and Endurance Limit. J. of Materi Eng and Perform 23, 2523–2532 (2014). https://doi.org/10.1007/s11665-014-1069-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1069-6