Abstract

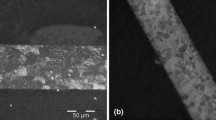

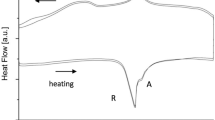

New ingot qualities, processed by optimized vacuum arc remelting (VAR), optimized vacuum induction melting followed by VAR and VAR followed by electron beam remelting, were compared with standard quality. Finished components as well as diamond-shaped samples representing a typical dimension of self-expanding stents were produced using Nitinol tubing drawn from the new ingot qualities. Metallographic longitudinal sections were prepared and analyzed to determine inclusion size and distributions of the various ingot qualities. Radial force and uniaxial tensile tests were used to determine the mechanical properties of fully processed material and tubing, respectively. Transformation temperatures of tubing as delivered from supplier and processed stents were measured by differential scanning calorimetry and deformation-and-free-recovery testing. Finally, fatigue tests were performed on diamond-shaped samples to evaluate the strain-life characteristics of the new ingot qualities. Results of this study are compared to ADMEDES historical data from standard Nitinol materials to gain an assessment of the new improved ingot qualities with regard to the production of Nitinol vascular implants. The latest developments in Nitinol ingot quality are highlighted and the results of the comparison from technical point of view are shown.

Similar content being viewed by others

References

S.M. Russell, Nitinol Melting and Fabrication, SMST 2000. Proceedings of the International Conference on Shape Memory and Superelastic Technologies, 2001, p 1–9

M.H. Wu, Fabrication of Nitinol Materials and Components, SMST 2001. Proceedings of the International Conference on Shape Memory and Superelastic Technologies, 2001, p 285–292

N. Morgan, A. Wick, J. DiCello, and R. Graham, Carbon and Oxygen Levels in Nitinol Alloys and the Implications for Medical Device Manufacture and Durability, SMST 2006. Proceedings of the International Conference on Shape Memory and Superelastic Technologies, 2008, p 821–828

M. Rahim, J. Frenzel, M. Frotscher, J. Pfetzing-Micklich, R. Steegmüller, M. Wohlschlögel, H. Mughrabi, and G. Eggeler, Impurity Levels and Fatigue Lives of Pseudoelastic NiTi, Acta Mater., 2013, 61, p 3667–3686

ASTM F2516-07, Standard Test Method for Tension Testing of Nickel-Titanium Superelastic Materials, ASTM International, West Conshohocken, 2007

ASTM F2129-08, Standard Test Method for Conducting Cyclic Potentiodynamic Polarization Measurements to Determine the Corrosion Susceptibility of Small Implant Devices, ASTM International, West Conshohocken, 2008

R.A. Corbett and S.N. Rosenbloom, An Assessment of ASTM F 2129 Test Results Comparing Nitinol to Other Implant Alloys, SMST 2006. Proceedings of the International Conference on Shape Memory and Superelastic Technologies, 2008, p 243–251

M. Wohlschlögel, R. Steegmüller, and A. Schüßler, Potentiodynamic Polarization Study on Electropolished Nitinol Vascular Implants, J. Biomed. Mater. Res. B, 2012, 100B(8), p 2231–2238

J.E. Schaffer and D.L. Plumley, Fatigue Performance of Nitinol Round Wire with Varying Cold Work Reductions, J. Mater. Eng. Perform., 2009, 18, p 563–568

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the International Conference on Shape Memory and Superelastic Technologies 2013, held May 20-24, 2013, in Prague, Czech Republic, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Steegmüller, R., Ulmer, J., Quellmalz, M. et al. Analysis of New Nitinol Ingot Qualities. J. of Materi Eng and Perform 23, 2450–2456 (2014). https://doi.org/10.1007/s11665-014-1054-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1054-0