Abstract

Two hydrothermal techniques under microwave irradiation were used to synthesize γ-MnO2 from 90°C to 150°C in 10−30 min. The first technique is based on reducing KMnO4 with MnSO4, and the second one involves liquid-phase oxidation between MnSO4 and (NH4)2S2O8. The structures and morphologies of the samples were analyzed using X-ray diffraction, scanning electron microscopy, and N2 physisorption measurements. The electrochemical properties were evaluated through cyclic voltammetry and electrochemical impedance spectroscopy. The γ-MnO2 materials obtained by the first technique mainly exhibited nanorods with diameters of 40–60 nm, and the samples obtained by the second technique showed flower-like microspheres with diameters of 1−2 µm; each flower was composed of nanosheets with a thickness of 10−20 nm. The processing time directly depends on the size of the nanorods. The sample synthesized by the first technique at 150°C and 10 min has the highest specific surface area of up to 59.08 m2 g−1 and mean pore diameter of 34.11 nm. Furthermore, this sample exhibits a near-rectangular cyclic voltammetry curves and high specific capacitance of 331.3 F g−1 in 0.1 M Na2SO4 solution at 5 mV s−1 scan rate.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, MnO2-based materials have attracted keen interest as electrochemical capacitors, as their specific capacitances are several times greater than that of conventional capacitors. In addition, manganese dioxides have high specific capacitance, high energy density, environmental friendliness, and natural abundance.1,2,–3 Gambou-Bosca and Belanger4 reported that one-electron transfer between Mn(III) and Mn(IV) produced a specific voltammetric charge of 1110 C g−1 and a specific capacitance of 1233 F g−1. However, most of the synthesized MnO2 materials show specific capacitance between 100 to 400 F g−1. In these materials, the difficulty in the electrolyte penetrating into the bulk of the oxide materials, caused by the dense morphology, limits the charge transfer reaction kinetics.

Two mechanisms have been proposed for charge storage in MnO2-based electrodes.5,6 One is based on the intercalation/decalation of protons in MnO2, implying a single electron transfer due to the Mn4+ to Mn3+ transition. The second mechanism is based on the surface adsorption of electrolyte cations (Li+, Na+, K+, H+) on MnO2. Some studies show that MnO2-based materials with high specific surface area, can exhibit good charge–discharge performance due to the appropriate contact area with the electrolyte.7,8

Based on various redox reactions, MnO2 materials can be successfully prepared by several methods, such as sol–gel,9 solid-state reaction,10 hydrothermal,11,12,–13 and precursor routes.14 Compared to these synthetic methods, the microwave-assisted route is a very fast and effective method to synthesize MnO2 materials. Additionally, microwave irradiation has been used to synthesize porous materials and nanocrystalline particles.15,16,17,18,–19

This study focused on the influence of the morphology and size of γ-MnO2 obtained by two microwave-assisted hydrothermal techniques on the specific capacitance. The first hydrothermal method produces γ-MnO2 through the reduction of permanganate solution, with Mn (II), according to the following reaction:20

The second method produces γ-MnO2 through the liquid-phase oxidation, with Mn (II), according to the following reaction:20,21

The morphology and microstructure of the γ-MnO2 samples were examined by X-ray diffraction (XRD) and scanning electron microscopy (SEM). The specific surface area was estimated by N2 adsorption–desorption tests and the electrochemical properties of the γ-MnO2, synthesized by the two microwave-assisted hydrothermal methods, were investigated by the cyclic voltammetry and electrochemical impedance spectroscopy techniques.

Experimental

A series of MnO2 nanostructures were synthesized by microwave-assisted hydrothermal techniques, following two procedures:

-

Method A: the reduction of KMnO4 with MnSO4, as shown in Eq. 1

-

Method B: involving a liquid-phase oxidation between MnSO4 and (NH4)2S2O8, as shown in Eq. 2

All chemicals were of analytical grade. In Method A, 0.298 g of KMnO4 and 0.212 g of MnSO4 were dissolved in 63 mL of distilled water at room temperature. In Method B, 0.862 g of (NH4)2S2O8 and 0.638 g of MnSO4 were also dissolved in 63 mL of distilled water at room temperature. The required reactants were used in the stoichiometric proportion according to reactions 1 and 2. The dissolved reactants for Methods A and B were transferred to a microwave-assisted hydrothermal reactor model Flexi-Wave from Milestone. The reactor was operated between 90°C and 150°C and held times of 10, 20, and 30 min for each studied temperature. Table I shows the experimental parameters used to synthesize MnO2. Samples A1 to A4 were obtained from Method A, at 90°C to 150°C and with a processing time between 10 min and 30 min. Samples B1 to B4 were obtained from Method B, also between 90°C and 150°C and from 10 min to 30 min.

In both the cases, using ammonium persulfate or potassium permanganate, the Teflon vessel in the autoclave was filed up to 70% volume. After reactions 1 and 2 were complete, the powders were filtered and washed several times with distilled water. Finally, the obtained product was dried at 60°C for 24 h in air.

The crystallographic structure of the materials was determined by XRD (Bruker AXS diffractometer model D8), equipped with Cu Kα radiation. Morphology and qualitative chemical analysis of samples obtained were determined with the SEM JEOL JSM 6701F and with the dispersive energy spectral (EDS) analysis. Nitrogen adsorption–desorption measurements were performed on a Quanthachrome Autosorb IQ surface and pore size analyzer. Specific surface areas and pore volume were calculated based on the N2 adsorption/desorption isotherms, by applying the Brunauer–Emmet–Teller (BET) method. The Barrett–Joyner–Halenda (BJH) approach was also used to calculate pore size distribution of the samples using the desorption data.

The electrochemical evaluation of the synthesized materials was performed by means of cyclic voltammetry and electrochemical impedance spectroscopy, using an EG&G potentiostat/galvanostat, Princeton Applied Research, Model 273A, and VersaSTAT 4, respectively. A typical 3-electrode electrochemical cell, consisting of a saturated calomel reference electrode ECS (Eo = 0.2415 V/ENH), placed inside a Luggin capillary, a graphite counter electrode, and a working electrode. The working electrode was prepared using 0.0004 g of Vulcan carbon and 0.006 g of the active material (MnO2), 10 µl of Nafion, and 60 µl of acetone. These materials were mixed and subjected to ultrasonic stirring for 30 min. From this mixture, 1 µl was taken and deposited on the surface of a previously polished and degreased glassy carbon electrode. The mass loading of MnO2 in each electrode was controlled to be approximately 0.085 mg. The electrolyte used was a 0.1 M Na2SO4 solution. Cyclic voltammetry measurements were carried out at scan rates from 5 mV s−1 to 100 mV s−1, over the voltage range of − 0.1 V to 1.3 V. The specific capacitance (Cs) values were calculated from the CV curves using the following equation:

where I is the response current, ν is the potential, ΔV = (Vc−Va) is the potential window, and m is the mass of the active material in the electrode. EIS measurements were performed at ± 10 mV applying a sinusoidal signal in a frequency range from 100 kHz to 0.01 Hz.

Results and Discussion

Structure of the Prepared MnO2

The XRD measurement was used to determine the crystal structure of the MnO2. Some samples produced a mixture of two or three different MnO2 polymorphic structures, such as Samples A1 and B4, presenting ε-MnO2 + γ-MnO2 and β-MnO2 + γ-MnO2, respectively. In this work, we have dealt only with the samples that showed the γ-MnO2 polymorphic structure completely.

Figures 1 and 2 show the XRD patterns of the as-synthesized MnO2 prepared by Methods A and B, respectively. There are four very broad peaks at approximately 2θ = 37.121°, 42.612°, 56.141°, and 57.363°, which demonstrate the formation of γ-MnO2 (JCPDS No. 00-014-0644), but these materials are low crystalline. The XRD patterns for the samples show broad peaks and high similitude. It is well known that XRD peak broadening occurs when the particle size falls in the nano range, due to the small crystallite size of the sample powder.22

The morphologies of the MnO2 products were observed by SEM. Figure 3 shows the images of the samples synthesized by Method A, using KMnO4 and MnSO4, which clearly reveals the presence of large nanorods with diameters of 40–60 nm and lengths ranging between hundreds of nanometers and several micrometers. The results in Fig. 3 show that the size of the nanorods directly depends on the processing time. As can be seen, the size of the nanorods in Sample A2, obtained with 30 min of processing, is greater than the nanorods obtained in Samples A3 and A4, whose processing times were 20 and 10 min, respectively. Sample A4 shows a mixture of nanorods and flower-like microspheres composed of nanosheets with a thickness of 10−20 nm. Based on the size and the crystal morphology, the mixture of nanorods and nanosheets of Sample A4 might be beneficial with respect to increase surface area and decrease diffusion path during the CV trials.

Figure 4 shows the morphology of all the MnO2 samples obtained by Method B, using MnSO4 and (NH4)2S2O8. Their morphology presents a flower-like microsphere with diameters of 1−2 µm. The high magnification SEM images demonstrate that the particles are covered with thin sheets protruding from them. Each flower is composed of ultra-thin nanosheets with a thickness of 10−20 nm. In this case, there was no observed noticeable effect of the processing time on the particle size, since the particle size of the samples is very similar despite the fact that Samples B1 and B3 were obtained after 20 min, while Sample 2 was obtained after 30 min.

The N2 adsorption–desorption studies were performed to determine the specific surface areas of the MnO2 samples. N2 adsorption–desorption isotherms of the MnO2 prepared by Methods A and B are shown in Figs. 5 and 6, respectively. The configuration of all the plots displays a typical type IV isotherm, with a hysteresis loop in the relative pressure region between 0.4 and 1.0 according to the IUPAC classification, which indicates that the tested materials expose mesoporosity.23

The shape and size of the hysteresis loops directly depends on the number and size of pores. Therefore, the hysteresis loop of Samples A2 and B1 are observed to be weakly pronounced, indicating a small number of mesopores. A feature common to the hysteresis loops is that the steep region of the desorption branch leading to the lower closure point occurs at a P/P° = 0.42, at its boiling point. In the case of Sample A4, the quantity of N2 absorbed at P/P° = 0.99 is about 350 cm3 g−1. This parameter is lower for the other samples.

The specific surface area, total pore volume, and average pore diameter for all MnO2 samples are listed in Table II. Although all the MnO2 samples exhibit the same type of adsorption–desorption isotherm, their surface area and pore size distribution are different. Sample A4 presents the highest pore volume, perhaps due to its morphology, mainly formed by nanorods. The surface area of Sample A4 is about 59.08 m2 g−1, calculated from the data in the P/P° region of 0.40−0.95. Compared to well-dispersed nanorods, flower-like microspheres have smaller surface areas because of the aggregation and large particle size. It is anticipated that samples with a high specific surface area will present higher electrochemical activity. The mesopores may be beneficial for ionic transportation through the electrolyte and improve the electrochemical performance.

The morphology change from nanorods of Sample A2 to a mixture of nanorods and nanosheets of Sample A4 can be explained in terms of concentration of KMnO4. Duan et al.24 reported that when the concentration of KMnO4 is low, it provides a low K+ ions concentration, and the nanostructures are generated under a thermodynamically preferential crystal growth regime. The crystal tends to form a closed shape with low Miller index faces. So the growth along a defined direction is favored and the assembly of nanorods is obtained. When a local increase of KMnO4 concentration is produced, the high concentrations of precursors lead to rapid formation of a large number of MnO2 nuclei in a short time. At higher supersaturation, the diffusion of source materials to existing nuclei might be hindered. Thus, the growth of those existing nuclei would be restrained to allow their growth to MnO2 nanosheets.

It is expected that increasing the reaction temperature allows the nanostructures to grow thicker;24 however, this effect was not observed clearly in this work, since the effect of processing time was more notorious, especially on the size of the nanorods of Samples A2 to A4.

Electrochemical Performance of the γ-MnO2 Samples

Figure 7 shows the measured CV curves of Samples A3 and A4, recorded at scan rates between 5 mV s−1 and 100 mV s−1. These CV curves are approximately rectangular, indicating the ideal capacitive behavior with a fast charge–discharge process and a low contact resistance.25,26 However, the rectangular shapes of CV curves turn quasi-rectangular when the scan rate is increased to 50 or 100 mV s−1, which is mainly because the redox reactions depend on the insertion–deinsertion of the alkali ion or protons from the electrolyte. At low scan rates, the ions from the electrolyte gain access to the electrode. When the scan rate is increased, the effective interaction between the ions and the electrode, and the effective surface adsorption of electrolyte cations, is reduced accordingly. Thus, there is a reduction in specific capacitance.27 In addition, the scan rate of the experiment controls how fast the applied potential is scanned. Faster rates lead to a decrease in the size of the diffusion layer.

The CV curves for A3 and A4 exhibit remarkably good symmetry. The redox peak is small and has a high-closed area in its CV curves, indicating that the specific capacitance is relatively high. The smoothness of the curve and the small redox peak illustrate the better capacitance performance and reversibility of the γ-MnO2 synthesized samples. The typical rectangular shape of the CV curves and the appearance of small redox peaks indicate that the charge storage of MnO2 materials involves the adsorption/desorption of protons (H+) or alkaline cations (Na+ or K+) into the oxide particles.28

Figure 8 shows the CV curves of the γ-MnO2 synthesized by Method B, recorded at scan rates between 5 mV s−1 and 100 mV s−1, in a 0.1 M Na2SO4 aqueous electrolyte. Cyclic voltammogram of Sample B1 in Fig. 8a shows a current peak at 0.9713 V in the cathodic sweep, at a scan rate of 100 mV s−1, and in the reverse direction, an oxidation peak at 0.7666 V. Similar voltammograms were recorded for Sample B2, showing a cathodic peak at 0.824 V and an anodic peak at 0.781 V. The current peak in the cathodic sweep is attributed to insertion of Na+ ion, followed by the reduction of Mn4+, while the anodic peak is attributed to deinsertion of Na+ ions. The reaction corresponding to sodiation/desodiation of Na+ in MnO2 is:29

Figure 8c shows that the CV curves of Sample B3 have a relatively rectangular and near-mirror-image shape. The CV curves of this sample do not show redox peaks at the potential window, demonstrating the high electrochemical reversibility and ideal electrochemical capacitive properties of the materials.30

Figure 8d shows the CV curves of all the γ-MnO2 synthesized materials by Methods A and B at the same scan rate (5 mV s−1). The area of the CV curve of Sample A4 is bigger than those of the other samples, which implies the highest specific capacitance values, Cs. Sample A4 also has the highest specific surface area of 59.08 cm2 g−1 in the range of mesopores, with an average pore diameter of about 34 nm. The highest Cs value of Sample A4 among all the tested samples may be ascribed to the lowest size of the nanorods and the interconnected tunnels arrangement, with a more opened structure that improves the intercalation of protons of alkali cations into the MnO2 bulk.

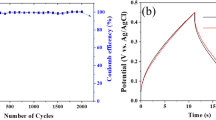

Figure 9 shows the relationships between the specific capacitances and the scan rate of γ-MnO2 materials prepared by methods A and B. The calculated Cs values from Eq. 3 of Samples A3 and A4 at 5 mV s−1 were 155.764 and 331.308 F g−1, respectively, whereas the Cs values of Samples B1, B2, and B3 at 5 mV s−1 were 243.414, 160.305, and 234.357 F g−1, respectively.

It is observed that the specific capacitance is higher at a low scanning rate (5 mV s−1), due to direct scanning speed impact on the diffusion of Na+ and H+ ions in the γ-MnO2. Faster sweep speeds lead to protons and cations only being able to diffuse in a very superficial layer of the electrode and not reaching the innermost pores of the material, greatly reducing the specific capacitance of the material.31 However, at low scan rates, the diffusion of ions from the electrolyte could gain access to more available pores of the electrode so as to lead to more insertion/deinsertion reactions and surface adsorption/desorption of electrolyte cations, since longer periods of time allow better interleaving of the atoms present. Then, a higher specific capacitance is obtained.

Figure 10 shows the variation of Cs of γ-MnO2 electrodes, with an increase in current density. A decrease in Cs with an increase in current density is observed for all the synthesized γ-MnO2 materials, which is due to a decrease in the utilization efficiency of the active materials at high current densities.

In the reversible redox process, there is a relationship between the voltammetric charge (q) and scan rate (ν).32 The voltammetric charge densities q (C g-1) can be obtained from the specific capacitance Cs (F g−1) and the potential window ΔV (V), through the expression:

The outer charge (q0), which results from the outer and most accessible active surface sites, can be estimated by the extrapolation of q to ν = ∞ from the q versus ν−1/2 plots. The plots of different γ-MnO2 samples are shown in Fig. 11, where the voltammetric charge increases with ν−1/2 (decrease with ν). At a low scan rate, protons have enough time to diffuse to the inner and less accessible active surface. The estimated charge density values at high scan rate (q0) are shown in Table III. The high value of q0 for γ-MnO2 of Sample A4 (104.5 C g−1) reveals that most surfaces of MnO2 are accessible to protons. Therefore, high specific capacitance and smaller decrease in specific capacitance at high scan rates are expected for γ-MnO2 of Sample A4.

The γ-MnO2 synthesized samples by Methods A and B are shown in Figs. 12 and 13, characterized after 200 and 500 cycles in 0.1 M Na2SO4, using the impedance technique. In the first set of materials, a similar response is observed due to the apparent formation of at least two semicircles in Nyquist plots, where the one observed at low frequencies exhibits a greater diameter. In addition, the semicircles obtained at 200 cycles for the A2 and A4 materials show a smaller diameter than that achieved at 500 cycles, which could be due to modifications of the supported oxide, likely related to its partial removal. In contrast, the semicircles obtained for A3 are similar, which can be associated with the synthesized oxide’s stability. Thus, it can be assumed that the electrochemical response at high frequencies is mainly due to MnO2, whereas the response at low frequencies is due to the glassy carbon substrate. To better visualize the oxide’s faradaic response, the magnified view of the high frequency region (see inset), where two different behaviors can be seen, is provided. It is also worth noting that the A3 and A4 materials exhibit lower impedance values due to a greater conductivity of the oxide formed under these conditions (less resistive).

Bode plots, exhibiting more apparent differences related to the employed frequencies, are also presented. Samples A2, A3, and A4 show the formation of a maximum phase angle at frequencies ranging between 1 and 10,000 Hz, which is a quite wide interval to be associated with a single-time constant. Furthermore, in all the cases, the maximum observed at 200 cycles is smaller than that achieved at 500 cycles. The impedance response in this frequency interval is due to the semiconducting properties of MnO2 synthesized under different conditions. The most important difference is recorded in the low frequency region, showing an increase in the angle for A3 and A4 materials, while Sample A2 displays a small increase. This difference in the angle response is due to the faradaic response of the substrate not covered by MnO2.

Figure 13 shows the impedance plots obtained for MnO2 synthesized by Method B. They exhibit the formation of two semicircles in the entire interval of frequencies, similar to those of Samples B1 and B2, but a little different from the one obtained for B3. This last sample hardly shows any response at high frequencies due to the oxide, which occurs only at 200 cycles, while at 500 cycles, the response is not obvious. As indicated earlier, it may be associated with the stability of oxides formed under different conditions, where B3 seems to be the most unstable. Likewise, plots obtained at 200 cycles show lower impedance values as compared to those at 500 cycles.

In the case of Bode plots, the formation of two maximum phase angles is observed throughout the entire frequency interval, very similar to those achieved for B1, B2, and B3 materials. Unlike the previous figure, the increase observed at intermediate frequencies is pretty evident in plots obtained at 500 cycles, indicating significant modifications in MnO2 coating on glassy carbon.

To analyze the electrochemical behavior of MnO2, impedance plots are simulated using the equivalent circuit shown in Fig. 14, which considers the following contributions: the first array (CPE1-R1,ct) is due to the capacitance of the supported oxide and the charge transfer process of Mn4+ ↔ Mn3+, including ion adsorption–desorption (i.e., H+ and/or Na+); the second array (CPE2-R2,ad) is due to ion adsorption; and the third array (CPE3-R3,ct) is due to the charge transfer on the electrode substrate (uncoated area). The fit of impedance plots is carried out using the Boukamp program and is represented in Figs. 12 and 13 by a continuous line, proving to be a good fit. The obtained data are shown in Table IV.

Among the values reported in this table, CPE1 and Rct stand out because both are related to the semiconducting properties of the oxide. The CPE1 values allow determining the capacitance values of the oxide formed by different methods and under different experimental conditions. It can be achieved using the following expression:33

where: Y0 is the base admittance of the constant phase element, R1,ct is the diameter of the loop and n1 is a power factor.

In this way, the calculated capacitance values are 6.4, 10 and 7.26 µF for Samples A2, A3 and A4 at 200 cycles, respectively; 4.66, 4.6 and 5.58 µF for Samples A2, A3 and A4 at 500 cycles, respectively. Similarly, the capacitance values are 3.3, 3.52 and 5.3 µF for Samples B1, B2 and B3 at 200 cycles, respectively; 2.4, 4.89 and 7.8 µF for Samples B1, B2 and B3 at 500 cycles, respectively. It is noteworthy that these capacitance values are in the same order of magnitude, which proves the formation of the same oxide in these materials.

The specific capacitance values obtained are 1066.66 and 776.66 µF g−1 for A2 at 200 and 500 cycles, respectively; 1666.66 and 766.66 µF g−1 for A3 at 200 and 500 cycles, respectively; and 1210 and 930 µF g−1 for A4 at 200 and 500 cycles, respectively. However, the capacitance values for Sample B1 vary from 550 µF g−1 to 400 µF g−1 at 200 and 500 cycles, respectively; for B2, from 586.66 µF g−1 to 815 µF g−1 at 200 and 500 cycles, respectively; and from 883.33 µF g−1 to 1300 µF g−1 for B3 at 200 and 500 cycles, respectively. It is important to note that these values are smaller than those obtained by CV, where the capacitive contribution of glassy carbon cannot be omitted during their perturbation.

Another important thing to be mentioned is the variation of the resistive element R1,ct at 200 and 500 cycles, for the different materials used: A2 (68.3 to 95.3 Ω), A3 (93.8 to 109.1 Ω), A4 (75.1 to 79.3 Ω), B1 (135.29 to 84.63 Ω), B2 (56.4 to 71.84 Ω) and B3 (55.19 to 38.57 Ω). These values are in the same order of magnitude, suggesting the velocity at which the reduction of Mn4+ to Mn3+ takes place and vice versa (oxidation). The second resistive element (R2,ad) is related to the process of ion adsorption on MnO2, whose morphological and structural characteristics are different. This parameter is observed to vary from 492.5 Ω to 1135.2 Ω, from 313.34 Ω to 370.16 Ω, and from 328.75 Ω to 828.62 Ω, for Samples A2, A3, and A4 at 200 and 500 cycles, respectively. Similarly, this parameter varies from 378.84 Ω to 5248.6 Ω, from 559.7 Ω to 4105 Ω, and from 3227.6 Ω to 18606 Ω for Samples B1, B2, and B3. It should be noted that, in all these cases, greater values are achieved at 500 cycles, which are further greater for Samples B1, B2, and B3. This indicates that the flower-like microsphere morphology of formed oxides is more likely to prevent the possible ion adsorption. This fact greatly affects the reversibility in MnO2 reduction/oxidation, easing its possible detachment from the substrate and an increase in this resistive element. The above findings allow us to suggest that Sample B3 is the one with the lowest stability of the formed oxide, while the greatest stability is provided by Sample A3 and, to a lower extent, by A4. Finally, the resistive element R3,ct results from the charge transfer taking place on the glassy carbon and can be considered to increase resistance values as the degree of oxide coating increases. This suggests that A3 and A4 materials exhibit a larger substrate coating as compared to Samples A2, B1, and B2, proving greater stability of these oxides probably due to the exhibited morphology.

Conclusions

Two microwave-assisted hydrothermal routes led to two γ-MnO2 mesoporous structures, nanorods, and flower-like microspheres. The results showed that reducing the synthesis time increases the specific surface area of the as-prepared MnO2 materials. The electrochemistry results of the MnO2 electrodes with different surface areas and pore characterizations indicated that the specific surface area of MnO2 plays an important role in capacitance. The γ-MnO2 sample with nanorods with a mean pore diameter of 34.11 nm and a specific surface area of 59.08 m2 g−1, obtained by the reduction of KMnO4 with MnSO4, showed the highest capacitance of 331.3 F g−1 at 5 mV s−1 scan rate. The estimated charge density value of this sample at a high scan rate reveals that a great part of the surface of MnO2 is accessible to protons. Additionally, the behavior of the formed oxide was evaluated using the impedance technique, where Samples A3 and A4 show high stability. On the contrary, oxide stability decreases when the deposit obtained by the second method exhibits the plateau-like morphology.

References

P. Ragupathy, H.N. Vasan, and N. Munichandraiah, J. Electrochem. Soc. 155, A34 (2008).

Z. Yang, Z. Mei, F. Xu, Y. Yao, W. Zhang, W. Qi, Q. Song, Z. Gao, and T. Zhao, J. Mater. Sci. 48, 2512 (2013).

M. Kim, Y. Hwang, and J. Kim, J. Mater. Sci. 48, 7652 (2013).

A. Gambou-Bosca, and D. Belanger, J. Power Sources 326, 595 (2016).

C. Wan, M. Cheng, Q. Zhang, and N. Jia, Powder Technol. 235, 706 (2013).

R. Han, S. Xing, Z. Ma, Y. Wu, and Y. Gao, J. Mater. Sci. 47, 3822 (2012).

J.-W. Wang, Y. Chen, and B.-Z. Chen, Met. Mater. Int. 20, 989 (2014).

S. Li, L. Qi, L. Lu, and H. Wang, RSC Adv. 2, 3298 (2012).

W. Tang, X. Shan, S. Li, H. Liu, X. Wu, and Y. Chen, Mater. Lett. 132, 317 (2014).

Q. Hao, L. Xu, G. Li, Z. Ju, C. Sun, H. Ma, and Y. Qian, J. Alloy Compd. 509, 6217 (2011).

X. Bai, X. Tong, Y. Gao, W. Zhu, C. Fu, J. Ma, T. Tan, C. Wang, Y. Luo, and H. Sun, Electrochim. Acta. 281, 525 (2018).

B. Kishore, V. Gopal, and M. Nookala, J. Appl. Chem. 5, 738 (2016).

J. Yan, T. Wei, J. Cheng, Z. Fan, and M. Zhang, Mater. Res. Bull. 45, 210 (2010).

M.S. Selim, Z. Hao, Y. Jiang, M. Yi, and Y. Zhang, Mater. Chem. Phys. 235, 121733 (2019).

O.S. Ibanova, M.-A. Teplonogova, A.D. Yapryntsev, A.E. Baranchikov, and V.K. Ivanov, Russ. J. Inorg. Chem. 63, 708 (2018).

M. Eckert, W. Peters, and J.-F. Drillet, Materials 11, 2399 (2018).

X. Zhang, W. Miao, C. Li, X. Sun, K. Wang, and Y. Ma, Mater. Res. Bull. 71, 111 (2015).

X. Tan, S. Liu, Q. Guo, J. Zhang, S. Liang, M. He, and J. Luo, Int. J. Energy Res. 44, 4556 (2020).

K. Chen, Y.D. Noh, K. Li, S. Komarneni, and D. Xue, J. Phys. Chem. C 117, 10770 (2013).

H. Adelkhani, T. Heidarpour, and K. Didehban, Russ. J. Electrochem. 53, 540 (2017).

C. Zhong, J.Z. Wang, Z.Z. Zhu, S.L. Chou, Z.X. Chen, Y. Li, and H.K. Liu, J. Solid State Electrochem. 14, 1743 (2010).

N. Pinna, Progr. Colloid Polym. Sci. 130, 29 (2005).

K.S.W. Sing, D.H. Everett, R.A.W. Haul, L. Moscou, R.A. Pierotti, J. Rouquerol, and T. Siemieniewska, Pure Appl. Chem. 57, 603 (1985).

X. Duan, J. Yang, H. Gao, J. Ma, L. Jiao, and W. Zheng, CrystEngComm 14, 4196 (2012).

V. Subramanian, H. Zhu, and B. Wei, J. Power Source 159, 361 (2006).

S.E. Chun, S.I. Pyun, and G.J. Lee, Electrochim. Acta 51, 6479 (2006).

C. Yuan, B. Gao, L. Su, and X. Zhang, J. Colloid Interface Sci. 322, 545 (2008).

E. Machefaux, T. Brousse, D. Belanger, and D. Guyomard, J. Power Sources 165, 651 (2007).

L. Bao, J. Zang, and X. Li, Nano Lett. 11, 1215 (2011).

S. Devaraj, and N. Munichandraiah, J. Phys. Chem. C 112, 4406 (2008).

M.J. Young, M. Neuber, A.C. Cavanagh, H. Sun, C.B. Musgrave, and S.M. Georgeb, J. Electrochem. Soc. 162, A2753 (2015).

J. Yan, Z. Fan, T. Wei, J. Cheng, B. Shao, K. Wang, L. Song, and M. Zhang, J. Power Sources 194, 1202 (2009).

M.A. Pech-Canul, and L.P. Chi-Canul, Corrosion 55, 948 (1999).

Acknowledgments

The authors wish to thank the National Council for Science and Technology (CONACYT), National Polytechnic Institute (IPN) and the Researcher National System (SNI) for the support of this research.

Funding

Author Antonio Romero-Serrano has received research grants from National Council for Science and Technology (CONACYT) of Mexico. This study was funded by CONACYT Grant Number A1-S 9692.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cuéllar-Herrera, L., Arce-Estrada, E., Romero-Serrano, A. et al. Microwave-Assisted Synthesis and Characterization of γ-MnO2 for High-Performance Supercapacitors. J. Electron. Mater. 50, 5577–5589 (2021). https://doi.org/10.1007/s11664-021-09098-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-021-09098-x