Abstract

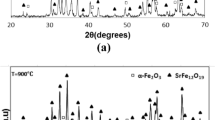

The present study describes the variation of grain size of natural hematite (α-Fe2O3) from bulk to nano-scale, owing to fractionation by ball milling and also the change in vital electrical properties of the products with respect to their bulk counterpart. Hematite, an important iron ore, is present in abundance in the deposits of most parts of the world. This fact was the rationale behind the selection of this mineral for the study. A gradual decrease in size via top-down synthesis technique was confirmed and the morphological parameters of the materials were analyzed using field emission scanning electron microscopy (FESEM) and corresponding pore diameter and surface area were determined by BET-BJH analysis. The studies were performed on three size fractions, namely, S1 (bulk mineral), S2 (bulk mineral, ball milled for 3 h) and S3 (bulk mineral, ball milled for 12 h). The purities of the natural mineral and its fractionated end products were estimated by using x-ray diffraction (XRD) and x-ray fluorescence (XRF) techniques. Increase in purity with decline in the particle size, especially in the nano-domain, was observed. The changes in dielectric properties of the materials with varying temperature were studied. Temperature dependence of the dielectric constant and ac conductivity were recorded, which indicated a remarkable augmentation in dielectric permittivity with reduction in size of the material. High dielectric constants of the smaller sized materials (S2 and S3) at low frequency signified their potential use in energy storage devices. Thus, using an easily available natural mineral as the starting material, an efficient energy storage appliance can be devised with a low-cost substance, synthesized by the simple approach of fractionation without employing any chemicals.

Graphic Abstract

Similar content being viewed by others

References

I. Lundström and S. Svensson, Curr. Appl. Phys. 2, 17 (2002).

N.A. Hoque, P. Thakur, P. Biswas, M.M. Saikh, S. Roy, B. Bagchi, S. Das, and P.P. Ray, J. Mater. Chem. A 6, 13848 (2018).

G. Wei, Y.U. Shouwen, and H. Ganyun, Nanotechnology 17, 1118 (2006).

Z.L. Wang and W. Wu Angew, Chem. Int. 51, 11700 (2012).

K.A. Homan, J. Shah, S. Gomez, H. Gensler, A.B. Karpiouk, L. Brannon-Peppas, and S.Y. Emelianov, J. Biomed Opt. 15, 021316 (2010).

A. Bala and T. Nautiyal, J. Magn. Magn. Mater. 320, 2201 (2008).

A.V. Anupama, W. Keune, and B. Sahoo, J. Magn. Magn. Mater. 439, 156 (2017).

Z. Fan, J. Chen, M. Wang, K. Cui, H. Zhou, and Y. Kuang, Diam. Relat. Mater. 15, 1478 (2006).

Z.H. Lin, G. Zhu, Y.S. Zhou, Y. Yang, P. Bai, J. Chen, and Z.L. Wang, AngewChem. Int. 52, 5065 (2013).

A. Balducci, S.S. Jeong, G.T. Kim, S. Passerini, M. Winter, M. Schmuck, G.B. Appetecchi, R. Marcilla, D. Mecerreyes, V. Barsukov, V. Khomenko, I. Cantero, I. De Meatza, M. Holzapfel, and N. Tran, J. Power Sources 196, 9719 (2011).

M.P. Lu, J. Song, M.Y. Lu, M.T. Chen, Y. Gao, L.J. Chen, and Z.L. Wang, Nano Lett. 9, 1223 (2009).

S. Vives, E. Gaffet, and C. Meunier, Mater. Sci. Eng. A 366, 229 (2004).

A.E. Mahmoud, H.S. Wasly, and M.A. Doheim, J. Eng. Sci. 42, 1430 (2014).

M. Ujihara, G.P. Carman, and D.G. Lee, Appl. Phys. Lett. 91, 093508 (2007).

E. Lefeuvre, A. Badel, C. Richard, and D. Guyomar, J. Intell. Mater. Syst. Struct. 16, 865 (2005).

W. Wu, S. Bai, M. Yuan, Y. Qin, Z.L. Wang, and T. Jing, ACS Nano 6, 6231 (2012).

C.H. Ng, H.N. Lim, Y.S. Lim, W.K. Chee, and N.M. Huang, Int. J. Energy Res. 39, 344 (2015).

C.M. Eggleston, Science 320, 184 (2008).

P. Robinson, R.J. Harrison, S.A. McEnroe, and R.B. Hargraves, Am. Min. 89, 725 (2004).

S.K. Boda, B. Basu, and B. Sahoo, J. Phys. Chem. C 119, 6539 (2015).

T.P. Raming, A.J. Winnubst, C.M. van Kats, and A.P. Philipse, J. Colloid Interface Sci. 249, 346 (2002).

H. Nagar, N.V. Kulkarni, S. Karmakar, B. Sahoo, I. Banerjee, P.S. Chaudhari, R. Pasricha, A.K. Das, S.V. Bhoraskar, S.K. Date, and W. Keune, Mater. Charact. 59, 1215 (2008).

J. Lian, X. Duan, J. Ma, P. Peng, T. Kim, and W. Zheng, ACS Nano 3, 3749 (2009).

M. Manjunatha, R. Kumar, A.V. Anupama, V.B. Khopkar, R. Damle, K.P. Rameshand, and B. Sahoo, J. Mater. Res. Technol. 8, 2192 (2019).

X. Zhang and Q. Li, Mater. Lett. 62, 988 (2008).

A.B. Rodriguez-Navarro, J. Appl. Crystallogr. 39, 905 (2006).

A.A. Bunaciu, E.G. UdriŞTioiu, and H.Y. Aboul-Enein, Crit. Rev. Anal. Chem. 45, 289 (2015).

A. Chauhan and P. Chauhan, J. Anal. Bioanal. Tech. 5, 1 (2014).

J.D. Hanawalt, H.W. Rinn, and L.K. Frevel, Ind. Eng. Chem. Anal. Ed. 10, 457 (1938).

C.E. Kril and R. Birringer, Philos. Mag. A 77, 621 (1998).

H.P. Klug and L.E. Alexander, X-Ray Diffraction Procedures: For Polycrystalline and Amorphous Materials, 2nd ed., (Hoboken: Wiley-VCH, 1974), p. 992.

J.S.J. Hargreaves, Catal. Struct. React. 2, 33 (2016).

H. Chen, Y. Chen, J. Yu, and J.S. Williams, Chem. Phys. Lett. 425, 315 (2006).

S. Singh, M.U. Aswath, R.D. Biswas, R.V. Ranganath, H.K. Choudhary, R. Kumar, and B. Sahoo, Case Stud. Constr. Mater. 11, e00266 (2019).

E. Darezereshki, Mater. Lett. 65, 642 (2011).

G. Ramis, G. Busca, and V. Lorenzelli, Mater. Chem. Phys. 29, 425 (1991).

W. Brostow and T. Datashvili, Chem. Chem. Technol. 2, 27 (2008).

J. Bhaskar Saikia, G. Parthasarathy, R.R. Borah, and R. Borthakur, Int. J. Earth Sci. 7, 873 (2016).

V.C. Farmer, Mineralogical Society (1974)

B.J. Saikia, G. Parthasarathy, and N.C. Sarmah, Nat. Sci. 7, 45 (2009).

B.J. Saikia, G. Parthasarathy, N.C. Sarmah, and G.D. Baruah, Bull. Mater. Sci. 31, 155 (2008).

Z.L.L. Yeung, R.C.W. Kwok, and K.N. Yu, Appl. Radiat. Isot. 58, 339 (2003).

S. Roy, A. Maity, P. Mandal, D.K. Chanda, K. Pal, S. Bardhan, and S. Das, Cryst. Eng. Commun. 20, 6338 (2018).

D.K. Chanda, P.S. Das, A. Samanta, A. Dey, A.K. Mandal, K.D. Gupta, T. Maitya, and A.K. Mukhopadhyay, Ceram. Int. 40, 11411 (2014).

D.K. Chanda, A. Samanta, A. Dey, P.S. Das, and A.K. Mukhopadhyay, J. Mater. Sci 52, 4910 (2017).

S. Roy, S. Bardhan, K. Pal, S. Ghosh, P. Mandal, S. Das, and S. Das, J. Alloys Compd. 763, 749 (2018).

S. Roy, S. Bardhan, D.K. Chanda, A. Maity, S. Ghosh, D. Mondal, S. Singh, and S. Das, Mater. Res. Express 7, 025020 (2020).

S. Das, S. Das, A. Roychowdhury, D. Das, and S. Sutradhar, J. Alloys Compd. 708, 231 (2017).

S. Bardhan, S. Roy, D.K. Chanda, S. Das, K. Pal, A. Chakraborty, R. Basu, and S. Das, Cryst. Growth Des. 19, 4588 (2019).

D. Chuprinko and K. Titov, Geophys. J. Int. 209, 186 (2017).

C.G. Koops, Phys. Rev. 83, 121 (1951).

S. Ganguly, K. Halder, N. Haque, S. Das, and S. Dastidar, Am. J. Res. Commun. 3, 68 (2015).

P. Thakur, A. Kool, B. Bagchi, N.A. Hoque, S. Das, and P. Nandy, RSC Adv. 5, 62819 (2015).

A.K. Jonscher, J. Mater. Sci. 16, 2037 (1981).

L.K. Sudha, S. Roy, and K.U. Rao, Int. J. Mater. Mech. Manuf. 2, 96 (2014).

Acknowledgments

Authors would like to thank the Department of Physics, Jadavpur University, for extending experimental facilities. S.D. would like to acknowledge DST-SERB (Grant No. EEQ/2018/000747) for funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghosh, S., Roy, S., Bardhan, S. et al. Effect of Size Fractionation on Purity, Thermal Stability and Electrical Properties of Natural Hematite. J. Electron. Mater. 50, 3836–3845 (2021). https://doi.org/10.1007/s11664-021-08878-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-021-08878-9