Abstract

A pulsed atomic-layer epitaxy growth technique has been introduced to substantially diminish the induced strain and oxygen incorporation on aluminium nitride films grown at standard pressure by metal organic chemical vapour deposition. The qualities of the as-deposited aluminium nitride films were studied by varying the aluminium nitride nucleation layer growth temperature at 700°C, 800°C, 900°C, 1000°C and 1100°C, respectively. The compressive strain inside the as-deposited aluminium nitride films, induced by the hetero-epitaxial growth on sapphire, was investigated through Raman spectroscopy by focusing on the evolution of E2 (high) peak frequency, where almost stress-free aluminium nitride films were attained at nucleation layer growth temperature of 1100°C. Then, the correlation between luminescence defect and level of foreign impurities respective to the varied nucleation layer growth temperatures were also systematically analysed through photoluminescence spectroscopy and x-ray photoelectron spectroscopy, respectively.

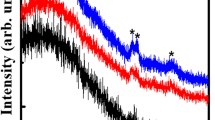

source and (b) the schematic of band-edge transition due to defect luminescence.

Similar content being viewed by others

References

M.S. Shur, and R. Gaska, M.S. Shur, and R. Gaska, IEEE Trans. Electron Dev., 2010, 57, p 12. https://doi.org/10.1109/TED.2009.2033768

J.K. Sheu, S.J. Chang, C.H. Kuo, Y.K. Su, L.W. Wu, Y.C. Lin, W.C. Lai, J.M. Tsai, G.C. Chi, and R.K. Wu, J.K. Sheu, S.J. Chang, C.H. Kuo, Y.K. Su, L.W. Wu, Y.C. Lin, W.C. Lai, J.M. Tsai, G.C. Chi, and R.K. Wu, IEEE Photon Technol. Lett., 2003, 15, p 18. https://doi.org/10.1109/LPT.2002.805852

L. Sang, M. Liao, N. Ikeda, Y. Koide, and M. Sumiya, L. Sang, M. Liao, N. Ikeda, Y. Koide, and M. Sumiya, Appl. Phys. Lett., 2011. https://doi.org/10.1063/1.3654155

I. Demir, H. Li, Y. Robin, R. McClintock, S. Elagoz, and M. Razeghi, I. Demir, H. Li, Y. Robin, R. McClintock, S. Elagoz, and M. Razeghi, J. Phys. D. Appl. Phys., 2018. https://doi.org/10.1088/1361-6463/aaa926

Y. Ohba, and A. Hatano, Y. Ohba, and A. Hatano, Jpn. J. Appl. Physics Part 2 Lett., 1996. https://doi.org/10.1143/jjap.35.l1013

H.J. Kim, S. Choi, D. Yoo, J.H. Ryou, R.D. Dupuis, R.F. Dalmau, P. Lu, and Z. Sitar, H.J. Kim, S. Choi, D. Yoo, J.H. Ryou, R.D. Dupuis, R.F. Dalmau, P. Lu, and Z. Sitar, Appl. Phys. Lett., 2008, 93, p 2006. https://doi.org/10.1063/1.2959064

H. Hirayama, S. Fujikawa, J. Norimatsu, T. Takano, K. Tsubaki, and N. Kamata, H. Hirayama, S. Fujikawa, J. Norimatsu, T. Takano, K. Tsubaki, and N. Kamata, Phys. Status Solid Curr. Top. Solid State Phys., 2009. https://doi.org/10.1002/pssc.200880958

M. Imura, K. Nakano, G. Narita, N. Fujimoto, N. Okada, K. Balakrishnan, M. Iwaya, S. Kamiyama, H. Amano, I. Akasaki, T. Noro, T. Takagi, and A. Bandoh, M. Imura, K. Nakano, G. Narita, N. Fujimoto, N. Okada, K. Balakrishnan, M. Iwaya, S. Kamiyama, H. Amano, I. Akasaki, T. Noro, T. Takagi, and A. Bandoh, J. Cryst. Growth., 2007, 298, p 257. https://doi.org/10.1016/j.jcrysgro.2006.10.043

Z. Chen, R.S. Qhalid Fareed, M. Gaevski, V. Adivarahan, J.W. Yang, A. Khan, J. Mei, and F.A. Ponce, Z. Chen, R.S. Qhalid Fareed, M. Gaevski, V. Adivarahan, J.W. Yang, A. Khan, J. Mei, and F.A. Ponce, Appl. Phys. Lett., 2006. https://doi.org/10.1063/1.2245436

V. Hoffmann, A. Knauer, C. Brunner, S. Einfeldt, M. Weyers, G. Trnkle, K. Haberland, J.T. Zettler, and M. Kneissl, V. Hoffmann, A. Knauer, C. Brunner, S. Einfeldt, M. Weyers, G. Trnkle, K. Haberland, J.T. Zettler, and M. Kneissl, J. Cryst. Growth., 2011, 315, p 5. https://doi.org/10.1016/j.jcrysgro.2010.09.048

X.H. Li, Y.O. Wei, S. Wang, H. Xie, T.T. Kao, M.M. Satter, S.C. Shen, P.D. Yoder, T. Detchprohm, R.D. Dupuis, A.M. Fischer, and F.A. Ponce, X.H. Li, Y.O. Wei, S. Wang, H. Xie, T.T. Kao, M.M. Satter, S.C. Shen, P.D. Yoder, T. Detchprohm, R.D. Dupuis, A.M. Fischer, and F.A. Ponce, J. Cryst. Growth., 2015, 414, p 76. https://doi.org/10.1016/j.jcrysgro.2014.10.007

J.P. Zhang, E. Kuokstis, Q. Fareed, H.M. Wang, J.W. Yang, G. Simin, M. AsifKhan, G. Tamulaitis, G. Kurilcik, S. Jursenas, A. Zukauskas, R. Gaska, and M. Shur, J.P. Zhang, E. Kuokstis, Q. Fareed, H.M. Wang, J.W. Yang, G. Simin, M. AsifKhan, G. Tamulaitis, G. Kurilcik, S. Jursenas, A. Zukauskas, R. Gaska, and M. Shur, Phys. Status Solid Appl. Res., 2001, 188, p 95. https://doi.org/10.1002/1521-396X(200111)188:1%3c95::AID-PSSA95%3e3.0.CO;2-Q

S. Ruffenach-Clur, O. Briot, J.L. Rouvière, B. Gil, and R.L. Aulombard, S. Ruffenach-Clur, O. Briot, J.L. Rouvière, B. Gil, and R.L. Aulombard, Mater. Sci. Eng. B., 1997, 50, p 219. https://doi.org/10.1016/S0921-5107(97)00166-9

A.A. Allerman, M.H. Crawford, A.J. Fischer, K.H.A. Bogart, S.R. Lee, D.M. Follstaedt, P.P. Provencio, and D.D. Koleske, A.A. Allerman, M.H. Crawford, A.J. Fischer, K.H.A. Bogart, S.R. Lee, D.M. Follstaedt, P.P. Provencio, and D.D. Koleske, J. Cryst. Growth, 2004. https://doi.org/10.1016/j.jcrysgro.2004.08.035

M.N.A. Rahman, A.F. Sulaiman, M.I.M.A. Khudus, K. Allif, N.A. Talik, S.H. Basri, and A. Shuhaimi, M.N.A. Rahman, A.F. Sulaiman, M.I.M.A. Khudus, K. Allif, N.A. Talik, S.H. Basri, and A. Shuhaimi, Jpn. J. Appl. Phys., 2019, 58, p SC1037. https://doi.org/10.7567/1347-4065/ab09d3

M. Balaji, A. Claudel, V. Fellmann, I. Gélard, E. Blanquet, R. Boichot, A. Pierret, B. Attal-Trétout, A. Crisci, S. Coindeau, H. Roussel, D. Pique, K. Baskar, and M. Pons, M. Balaji, A. Claudel, V. Fellmann, I. Gélard, E. Blanquet, R. Boichot, A. Pierret, B. Attal-Trétout, A. Crisci, S. Coindeau, H. Roussel, D. Pique, K. Baskar, and M. Pons, J. Alloys Compd., 2012, 526, p 103. https://doi.org/10.1016/j.jallcom.2012.02.111

M. Takeuchi, H. Shimizu, R. Kajitani, K. Kawasaki, Y. Kumagai, A. Koukitu, and Y. Aoyagi, M. Takeuchi, H. Shimizu, R. Kajitani, K. Kawasaki, Y. Kumagai, A. Koukitu, and Y. Aoyagi, J. Cryst. Growth., 2007, 298, p 336. https://doi.org/10.1016/j.jcrysgro.2006.10.140

M. Imura, K. Nakano, N. Fujimoto, N. Okada, K. Balakrishnan, M. Iwaya, S. Kamiyama, H. Amano, I. Akasaki, T. Noro, T. Takagi, and A. Bandoh, M. Imura, K. Nakano, N. Fujimoto, N. Okada, K. Balakrishnan, M. Iwaya, S. Kamiyama, H. Amano, I. Akasaki, T. Noro, T. Takagi, and A. Bandoh, Jpn. J. Appl. Phys Part 1 Regul. Pap. Short Notes Rev. Pap., 2007, 46, p 1458. https://doi.org/10.1143/JJAP.46.1458

J. Song, D. Chen, and J. Han, J. Song, D. Chen, and J. Han, J. Cryst. Growth., 2015, 415, p 127. https://doi.org/10.1016/j.jcrysgro.2014.12.041

M.N. Abd Rahman, A. Shuhaimi, Y. Yusuf, H. Li, A.F. Sulaiman, M.E. Alif Samsudin, N. Zainal, and M.I.M. Abdul Khudus, M.N. Abd Rahman, A. Shuhaimi, Y. Yusuf, H. Li, A.F. Sulaiman, M.E. Alif Samsudin, N. Zainal, and M.I.M. Abdul Khudus, Superlattices Microstruct., 2018, 120, p 319. https://doi.org/10.1016/j.spmi.2018.05.024

R. Chierchia, T. Böttcher, S. Figge, M. Diesselberg, H. Heinke, and D. Hommel, R. Chierchia, T. Böttcher, S. Figge, M. Diesselberg, H. Heinke, and D. Hommel, Phys. Status Solidi Basic Res., 2001, 228, p 403. https://doi.org/10.1002/1521-3951(200111)228:2%3c403::AID-PSSB403%3e3.0.CO;2-5

M. Kuball, M. Kuball, Raman spectroscopy of GaN, AlGaN and AlN for process and growth monitoring/control Surf. Interface Anal., 2001, 31, p 987. https://doi.org/10.1002/sia.1134

H. Wang, S.L. Li, H. Xiong, Z.H. Wu, J.N. Dai, Y. Tian, Y.Y. Fang, and C.Q. Chen, H. Wang, S.L. Li, H. Xiong, Z.H. Wu, J.N. Dai, Y. Tian, Y.Y. Fang, and C.Q. Chen, J. Electron. Mater., 2012, 41, p 466. https://doi.org/10.1007/s11664-011-1798-3

R. Yakimova, A. Kakanakova-Georgieva, G.R. Yazdi, G.K. Gueorguiev, and M. Syväjärvi, R. Yakimova, A. Kakanakova-Georgieva, G.R. Yazdi, G.K. Gueorguiev, and M. Syväjärvi, J. Cryst. Growth, 2005. https://doi.org/10.1016/j.jcrysgro.2005.03.015

M.N. Abd Rahman, N.A. Talik, M.I.M. Abdul Khudus, A.F. Sulaiman, K. Allif, N.M. Zahir, and A. Shuhaimi, M.N. Abd Rahman, N.A. Talik, M.I.M. Abdul Khudus, A.F. Sulaiman, K. Allif, N.M. Zahir, and A. Shuhaimi, CrystEngComm., 2019, 21, p 2009. https://doi.org/10.1039/C9CE00014C

M.N.A.R. Yusnizam Yusuf, A. Anuar, M.R. Mahat, N. Chanlek, N.A. Talik, M.I.M. Abdul Khudus, N. Zainal, W.H. Abd Majid, and A. Shuhaimi, M.N.A.R. Yusnizam Yusuf, A. Anuar, M.R. Mahat, N. Chanlek, N.A. Talik, M.I.M. Abdul Khudus, N. Zainal, W.H. Abd Majid, and A. Shuhaimi, CrystEngComm., 2020. https://doi.org/10.1039/D0CE00113A

S. Raghavan, and J.M. Redwing, S. Raghavan, and J.M. Redwing, J. Appl. Phys., 2004, 96, p 2995. https://doi.org/10.1063/1.1777812

A.R. Goñi, H. Siegle, C. Thomsen, K. Syassen, and J.M. Wagner, A.R. Goñi, H. Siegle, C. Thomsen, K. Syassen, and J.M. Wagner, Phys. Rev. B Condens. Matter Mater. Phys., 2001, 64, p 035205. https://doi.org/10.1103/PhysRevB.64.035205

J.Z. Li, Z.Z. Chen, Q.Q. Jiao, Y.L. Feng, S. Jiang, Y.F. Chen, T.J. Yu, S.F. Li, and G.Y. Zhang, J.Z. Li, Z.Z. Chen, Q.Q. Jiao, Y.L. Feng, S. Jiang, Y.F. Chen, T.J. Yu, S.F. Li, and G.Y. Zhang, CrystEngComm, 2015, 17, p 4469. https://doi.org/10.1039/c5ce00476d

M. Miyoshi, A. Watanabe, and T. Egawa, M. Miyoshi, A. Watanabe, and T. Egawa, Semicond. Sci. Technol, 2016. https://doi.org/10.1088/0268-1242/31/10/105016

L. Shen, T. Cheng, L. Wu, X. Li, and Q. Cui, L. Shen, T. Cheng, L. Wu, X. Li, and Q. Cui, J. Alloys Compd., 2008, 465, p 562. https://doi.org/10.1016/j.jallcom.2007.11.007

D. Chen, J. Wang, D. Xu, and Y. Zhang, D. Chen, J. Wang, D. Xu, and Y. Zhang, Vacuum, 2009, 83, p 865. https://doi.org/10.1016/j.vacuum.2008.09.003

I.A. Weinstein, A.S. Vokhmintsev, and D.M. Spiridonov, I.A. Weinstein, A.S. Vokhmintsev, and D.M. Spiridonov, Diam. Relat. Mater., 2012, 25, p 59. https://doi.org/10.1016/j.diamond.2012.02.004

V.A. Soltamov, I.V. Ilyin, A.A. Soltamova, D.O. Tolmachev, N.G. Romanov, A.S. Gurin, E.N. Mokhov, and P.G. Baranov, V.A. Soltamov, I.V. Ilyin, A.A. Soltamova, D.O. Tolmachev, N.G. Romanov, A.S. Gurin, E.N. Mokhov, and P.G. Baranov, Phys. Status Solidi Curr. Top. Solid State Phys., 2012, 9, p 745. https://doi.org/10.1002/pssc.201100433

S. Schweizer, U. Rogulis, J.M. Spaeth, L. Trinkler, and B. Berzina, S. Schweizer, U. Rogulis, J.M. Spaeth, L. Trinkler, and B. Berzina, Phys. Status Solidi Basic Res., 2000, 219, p 171. https://doi.org/10.1002/1521-3951(200005)219:1%3c171::AID-PSSB171%3e3.0.CO;2-0

T. Schulz, M. Albrecht, K. Irmscher, C. Hartmann, J. Wollweber, and R. Fornari, T. Schulz, M. Albrecht, K. Irmscher, C. Hartmann, J. Wollweber, and R. Fornari, Phys. Status Solidi Basic Res., 2011, 248, p 1513. https://doi.org/10.1002/pssb.201046616

L. Shen, N. Wang, and X. Xiao, L. Shen, N. Wang, and X. Xiao, Mater. Lett., 2013, 94, p 150. https://doi.org/10.1016/j.matlet.2012.12.042

G.A. Slack, H. Przybylinska, and G.D. Watkins, G.A. Slack, H. Przybylinska, and G.D. Watkins, Phys. Rev. B Condens. Matter Mater. Phys., 1999, 59, p 1937. https://doi.org/10.1103/PhysRevB.59.1937

M. Lamprecht, V.N. Jmerik, R. Collazo, Z. Sitar, S.V. Ivanov, and K. Thonke, M. Lamprecht, V.N. Jmerik, R. Collazo, Z. Sitar, S.V. Ivanov, and K. Thonke, Phys. Status Solidi Basic Res., 2017. https://doi.org/10.1002/pssb.201600714

A. Mahmood, R. Machorro, S. Muhl, J. Heiras, F.F. Castillón, M.H. Farías, and E. Andrade, A. Mahmood, R. Machorro, S. Muhl, J. Heiras, F.F. Castillón, M.H. Farías, and E. Andrade, Diam. Relat. Mater., 2003, 12, p 1315. https://doi.org/10.1016/S0925-9635(03)00076-1

L. Rosenberger, R. Baird, E. McCullen, G. Auner, and G. Shreve, L. Rosenberger, R. Baird, E. McCullen, G. Auner, and G. Shreve, Surf. Interface Anal., 2008, 40, p 1254. https://doi.org/10.1002/sia.2874

G.A. Slack, L.J. Schowalter, D. Morelli, and J.A. Freitas, G.A. Slack, L.J. Schowalter, D. Morelli, and J.A. Freitas, J. Cryst. Growth, 2002. https://doi.org/10.1016/S0022-0248(02)01753-0

M.N. Abd Rahman, A. Shuhaimi, O.C. Seng, G. Tan, A. Anuar, N.A. Talik, M.I.M. Abdul Khudus, N. Chanlek, and W.H. AbdMajid, M.N. Abd Rahman, A. Shuhaimi, O.C. Seng, G. Tan, A. Anuar, N.A. Talik, M.I.M. Abdul Khudus, N. Chanlek, and W.H. AbdMajid, J. Mater. Sci. Mater. Electron., 2021. https://doi.org/10.1007/s10854-020-05070-3

F. Liang, P. Chen, D.G. Zhao, D.S. Jiang, Z.J. Zhao, Z.S. Liu, J.J. Zhu, J. Yang, W. Liu, X.G. He, X.J. Li, X. Li, S.T. Liu, H. Yang, J.P. Liu, L.Q. Zhang, Y.T. Zhang, and G.T. Du, F. Liang, P. Chen, D.G. Zhao, D.S. Jiang, Z.J. Zhao, Z.S. Liu, J.J. Zhu, J. Yang, W. Liu, X.G. He, X.J. Li, X. Li, S.T. Liu, H. Yang, J.P. Liu, L.Q. Zhang, Y.T. Zhang, and G.T. Du, Appl. Phys. A Mater. Sci. Process., 2016. https://doi.org/10.1007/s00339-016-0312-4

M. Alevli, C. Ozgit, I. Donmez, and N. Biyikli, M. Alevli, C. Ozgit, I. Donmez, and N. Biyikli, Phys. Status Solidi Appl. Mater. Sci., 2012, 209, p 266. https://doi.org/10.1002/pssa.201127430

P. Martin, R. Netterfield, T. Kinder, and A. Bendavid, P. Martin, R. Netterfield, T. Kinder, and A. Bendavid, Appl. Opt., 1992, 31, p 6734. https://doi.org/10.1364/ao.31.006734

H. Kim, H.J. Yoon, and B.J. Choi, H. Kim, H.J. Yoon, and B.J. Choi, Nanoscale Res. Lett., 2018. https://doi.org/10.1186/s11671-018-2645-8

D. Manova, V. Dimitrova, W. Fukarek, and D. Karpuzov, D. Manova, V. Dimitrova, W. Fukarek, and D. Karpuzov, Surf. Coatings Technol., 1998, 106, p 205. https://doi.org/10.1016/S0257-8972(98)00527-1

M. Arbab, and J.J. Finley, M. Arbab, and J.J. Finley, J. Vaccum Sci. Technol. A Vaccum Surf. Film, 1994, 12, p 1528. https://doi.org/10.1116/1.579350

P. Motamedi, and K. Cadien, P. Motamedi, and K. Cadien, Appl. Surf. Sci., 2014, 315, p 104. https://doi.org/10.1016/j.apsusc.2014.07.105

R.A. Youngman, and J.H. Harris, R.A. Youngman, and J.H. Harris, J. Am. Ceram. Soc., 1990, 73, p 3238. https://doi.org/10.1111/j.1151-2916.1990.tb06444.x

H.M. Liao, R.N.S. Sodhi, and T.W. Coyle, H.M. Liao, R.N.S. Sodhi, and T.W. Coyle, J. Vaccum Sci. Technol. A Vaccum Surf. Film, 1993, 11, p 2681. https://doi.org/10.1116/1.578626

M. García-Méndez, S. Morales-Rodríguez, S. Shaji, B. Krishnan, and P. Bartolo-Pérez, M. García-Méndez, S. Morales-Rodríguez, S. Shaji, B. Krishnan, and P. Bartolo-Pérez, Surf. Rev. Lett., 2011, 18, p 23. https://doi.org/10.1142/S0218625X1101445X

O.H. Kim, D. Kim, and T. Anderson, O.H. Kim, D. Kim, and T. Anderson, J. Vaccum Sci. Technol. A Vaccum Surf. Film, 2009, 27, p 923. https://doi.org/10.1116/1.3106619

M. Kazan, B. Ruffĺ, C. Zgheib, and P. Masri, M. Kazan, B. Ruffĺ, C. Zgheib, and P. Masri, J. Appl. Phys., 2005. https://doi.org/10.1063/1.2137461

J.H. Harris, R.A. Younvman, and R.G. Teller, J.H. Harris, R.A. Younvman, and R.G. Teller, J. Mater. Res., 1990, 5, p 1763. https://doi.org/10.1557/JMR.1990.1763

F. Jose, R. Ramaseshan, S. Dash, S. Bera, A.K. Tyagi, and B. Raj, F. Jose, R. Ramaseshan, S. Dash, S. Bera, A.K. Tyagi, and B. Raj, J. Phys. D. Appl. Phys., 2010, 43, p 075304. https://doi.org/10.1088/0022-3727/43/7/075304

G.A. Slack, G.A. Slack, J. Phys. Chem. Solids., 1973, 34, p 321. https://doi.org/10.1016/0022-3697(73)90092-9

Y. Zhang, Y. Zhang, J. Mater. Sci. Lett., 2002, 21, p 1603. https://doi.org/10.1023/A:1020321600329

C. Ozgit, I. Donmez, M. Alevli, and N. Biyikli, C. Ozgit, I. Donmez, M. Alevli, and N. Biyikli, J. Vaccum Sci. Technol. A Vacuum Surf. Film., 2012, 30, p 01A124. https://doi.org/10.1116/1.3664102

Acknowledgments

The author thanks to OSRAM Opto Semiconductor SDN BHD for the sponsorship studies, the Ministry of Higher Education (MOHE) Long Term Research Grant Scheme (LRGS) under project no: LR001A-2016A and CREST Gallium Nitride on Gallium Nitride Collaboration (PV015-2015) for project funding as well as my family Haji Abd Rahman Ulang, Hajah Patimah Mohd Yusoff, Nur Akmarina, Mohd Rezza, Mohd Edzuan, Nur Edzatul Aina, Muhammad Radzi, Muhammad Aizzat, my wife Mrs Dahliah Fatin Abdul Ghani together with my kids Muhammad Iman Rifqi and Muhammad Iman Hariz for their great support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abd Rahman, M.N., Shuhaimi, A., Abdul Khudus, M.I.M. et al. Diminishing the Induced Strain and Oxygen Incorporation on Aluminium Nitride Films Deposited Using Pulsed Atomic-Layer Epitaxy Techniques at Standard Pressure MOCVD. J. Electron. Mater. 50, 2313–2322 (2021). https://doi.org/10.1007/s11664-021-08768-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-021-08768-0