Abstract

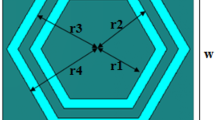

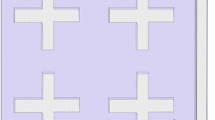

A method of fabricating and characterizing terahertz frequency selective surface filters from a low-cost silver adhesive tape has been reported in this paper. The proposed filter was initially evaluated numerically using the method of moment’s simulation and verified experimentally by terahertz time-domain spectroscopy technique. The numerical results show that the cross aperture frequency selective surface has angle-resolved and polarization independent operation. The proposed silver adhesive tape and conventional copper-based frequency selective surface have been fabricated using a laser micromachining process. A 20 ns-pulsed laser operating at 1064 nm wavelength was used to create the desired structure by ablation mechanism in the copper film. The pattern ablated by the laser is a cross-shaped slit on copper and silver adhesive tape. The patterned structure was designed to resonate at 0.25 THz by the cross-arm structure. The fabricated structure shows the peak transmittance of 90% with a full-width half maximum of 48% with respect to the resonance. The adhesive tape based frequency selective surface provides similar transmission characteristics compared to a conventional frequency selective surface.

Similar content being viewed by others

References

M. Tonouchi, Nat. Photonics 1, 97 (2007).

J. Li, Y. Li, and L. Zhang, IEEE Photonics Technol. Lett. 30, 238 (2017).

D.W. Porterfield, J.L. Hesler, R. Densing, E.R. Mueller, T.W. Crowe, and R.M. Weikle, Appl. Opt. 33, 6046 (1994).

P.A.R. Ade, G. Pisano, C. Tucker, and S. Weaver, Proc. SPIE. 6275, 62750U (2006).

M.J. Madou, Fundamentals of Microfabrication and Nanotechnology, 3rd ed. (Boca Raton: CRC Press, 2011).

M. Esakkimuthu, S.B. Suseela, R. Sankararajan, A. Gupta, G. Rana, and S. Prabhu, J. Laser Micro Nanoeng. 12, 313 (2017).

N. Ahmed, S. Darwish, and A.M. Alahmari, Mater. Manuf. Process. 31, 1121 (2016).

S. Mishra and V. Yadava, Opt. Lasers Eng. 73, 89 (2015).

J. Bonse, S. Hohm, S.V. Kirner, A. Rosenfeld, and J. Kruger, IEEE J. Sel. Top. Quantum Electron. 23, 1 (2017).

K.G. Nichols, Proc. IEE 116, 2093 (1969).

R. Jordan, D. Cole, G. Lunney, K. Mackay, and D. Givord, Appl. Surf. Sci. 86, 24 (1995).

A. Bogaerts, Z. Chen, and D. Bleiner, J. Anal. At. Spectrom. 21, 384 (2006).

C.R. Phipps, T.P. Turner, R.F. Harrison, G.W. York, W.Z. Osborne, G.K. Anderson, X.F. Corlis, L.C. Haynes, H.S. Steele, K.C. Spicochi, and T.R. King, J. Appl. Phys. 64, 1083 (1988).

T.J. Hirsch, R.F. Miracky, and C. Lin, Appl. Phys. Lett. 57, 1357 (1990).

A. Bogaerts, Z. Chen, R. Gijbels, and A. Vertes, Spectrochim. Acta Part B At. Spectrosc. 58, 1867 (2003).

M. Aghaei, S. Mehrabian, and S.H. Tavassoli, J. Appl. Phys. 104, 053303 (2008).

K. Tada, G. Cohoon, K. Kieu, M. Mansuripur, and R.A. Norwood, IEEE Photonic Technol. Lett. 85712, 430 (2012).

N. Farid, P. Dasgupta, H. Chan, D. Milne, and G.M. O’Connor, Opt. InfoBase Conf. Pap. Part F82-C, 6736 (2017).

C. Mcdonnell, D. Milne, H. Chan, D. Rostohar, and G.M.O. Connor, Opt. Lasers Eng. 80, 73 (2016).

E. Manikandan, B.S. Sreeja, S. Radha, and R.N. Bathe, Mater. Lett. 229, 320 (2018).

N. Born, R. Gente, and M. Koch, Electron. Lett. 51, 1012 (2015).

E. Manikandan, B.S. Sreeja, S. Radha, R.N. Bathe, and R. Jain, J. Infrared Millime. Terahertz Waves 40, 38 (2018).

E. Manikandan, B.S. Sreeja, S. Radha, M. Duraiselvam, A. Gupta, and S. Prabhu, Opt. Eng. 58, 011007 (2018).

A. Ferraro, D.C. Zografopoulos, R. Caputo, and R. Beccherelli, IEEE J. Sel. Top. Quantum Electron. 23, 8501308 (2017).

P.D. Cunningham, N.N. Valdes, F.A. Vallejo, L.M. Hayden, B. Polishak, X. Zhou, J. Luo, A.K. Jen, J.C. Williams, and R.J. Twieg, J. Appl. Phys. 109, 043505 (2011).

Z. Song, Z. Zhao, H. Zhao, W. Peng, X. He, and W. Shi, J. Appl. Phys. 118, 043108 (2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Esakkimuthu, M., Suseela, S.B., Sankarrajan, R. et al. Microfabrication of Low Cost Frequency Selective Surface for Terahertz Wave by Laser Ablation. J. Electron. Mater. 48, 2423–2429 (2019). https://doi.org/10.1007/s11664-019-07008-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-019-07008-w