Abstract

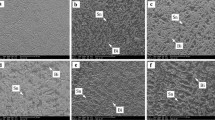

A characterization of mechanical and micromechanical properties of SAC305 solder wire under varied strain rates and temperatures was performed using tensile and nanoindentation tests. The evolution of SAC305 lead-free solder wire grains was compared in samples that were subjected to various strain rates and temperatures using tensile tests based on ASTM E12 standards. Different behaviours of mechanical properties, micromechanical properties, and microstructure evolution of SAC305 solder wire were observed when either temperature or strain rate was held constant and the other varied. Both tensile and nanoindentation tests produced qualitative results, such as dynamic recovery and occurrence of pop-in events, that reflected changes of microstructure. It was observed that some of the mechanical properties of SAC305 solder wire, namely yield strength (YS), ultimate tensile strength (UTS) and Young’s modulus, showed the same trends, but with lower values, compared to micromechanical properties obtained from nanoindentation tests based upon hardness and reduced modulus. Microstructure examination further confirms that the YS, UTS and hardness values increase with more solder wire grain refinement. SAC305 solder wire also maintained an equiaxed structure under various strain rates and temperatures.

Similar content being viewed by others

References

H. Ma, J. Mater. Sci. 44, 3841 (2009).

W. Lee, L. Nguyen, and G. Selvaduray, Microelectron. Reliab. 40, 231 (2000).

H. Ma and J.C. Suhling, J. Mater. Sci. 44, 1141 (2009).

B.S.S.C. Rao, K.M. Kumar, V. Kripesh, and K.Y. Zeng, Mater. Sci. Eng., A 528, 4166 (2011).

F. Zhu, H. Zhang, R. Guan, and S. Liu, J. Alloys Compd. 438, 100 (2007).

C. Andersson, P. Sun, and J. Liu, J. Alloys Compd. 457, 97 (2008).

A. Fawzy, Mater. Charact. 58, 323 (2007).

I. Abdullah, M.N. Zulkifli, A. Jalar, and R. Ismail, Solder (SSMT: Surf. Mt. Technol, 2017).

A.C. Fischer-Cripps, Surf. Coatings Technol. 200, 4153 (2006).

Y. Sun, J. Liang, Z.-H. Xu, G. Wang, and X. Li, J. Mater. Sci.: Mater. Electron. 19, 514 (2007).

J.P. Lucas, H. Rhee, F. Guo, and K.N. Subramanian, J. Electron. Mater. 32, 1375 (2003).

L. Yang, W. Zhou, Y. Ma, X. Li, Y. Liang, W. Cui, and P. Wu, Mater. Sci. Eng., A 667, 368 (2016).

W. Oliver and G. Pharr, J. Mater. Res. 7, 1564 (1992).

W.C. Oliver and G.M. Pharr, J. Mater. Res. 19, 3 (2011).

P.T. Vianco, J.A. Rejent, and A.C. Kilgo, J. Electron. Mater. 32, 142 (2003).

A. Fischer-Cripps, Vacuum 58, 569 (2000).

A. Gouldstone, H.-J. Koh, K.-Y. Zeng, A.E. Giannakopoulos, and S. Suresh, Acta Mater. 48, 2277 (2000).

D. Kiener, K. Durst, M. Rester, and A.M. Minor, JOM 61, 14 (2009).

E. Rabkin, J.K. Deuschle, and B. Baretzky, Acta Mater. 58, 1589 (2010).

L. Lu, S.X. Li, and K. Lu, Scr. Mater. 45, 1163 (2001).

M.J. Esfandyarpour and R. Mahmudi, Mater. Sci. Eng., A 530, 402 (2011).

F.X. Che, W.H. Zhu, E.S.W. Poh, X.W. Zhang, and X.R. Zhang, J. Alloys Compd. 507, 215 (2010).

F. Yang and J.C.M. Li, in Lead-Free Electron. Solder. (Springer US, Boston, MA, 2007), pp. 191–210.

X.Q. Shi, W. Zhou, H.L.J. Pang, and Z.P. Wang, J. Electron. Packag. 121, 179 (1999).

C.R. Siviour, S.M. Walley, W.G. Proud, and J.E. Field, J. Phys. D Appl. Phys. 38, 4131 (2005).

M. Woodmansee and R. Neu, Acta Mater. 54, 197 (2006).

Y. Cheng and T.A. Siewert, J. Electron. Mater. 32, 535 (2003).

C. Basaran and J. Jiang, Mech. Mater. 34, 349 (2002).

D.E.J. Armstrong, A.J. Wilkinson, and S.G. Roberts, J. Mater. Res. 24, 3268 (2009).

I.M. Hutchings, J. Mater. Res. 24, 581 (2011).

V.M.F. Marques, C. Johnston, and P.S. Grant, Acta Mater. 61, 2460 (2013).

P.T. Vianco, J.A. Rejent, and J.J. Martin, JOM 55, 50 (2003).

I. Abdullah, M.N. Zulkifli, A. Jalar, and R. Ismail, Solder. Surf. Mt. Technol. 29, 110 (2017).

J.L. Milner, F. Abu-Farha, C. Bunget, T. Kurfess, and V.H. Hammond, Mater. Sci. Eng., A 561, 109 (2013).

Acknowledgement

This work is supported by the Universiti Kebangsaan Malaysia (UKM) under Research University Grants (UKM-OUP-NBT-29-143/2011, OUP-2012-120 and DIP-2012-14).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abdullah, I., Zulkifli, M.N., Jalar, A. et al. Relationship of Mechanical and Micromechanical Properties with Microstructural Evolution of Sn-3.0Ag-0.5Cu (SAC305) Solder Wire Under Varied Tensile Strain Rates and Temperatures. J. Electron. Mater. 48, 2826–2839 (2019). https://doi.org/10.1007/s11664-019-06985-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-019-06985-2