Abstract

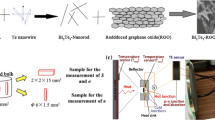

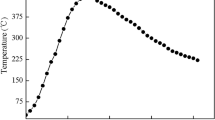

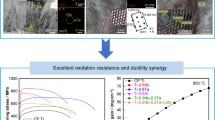

Mg2Si based materials are attractive candidates for mid-temperature (hot side around 800 K) thermoelectric generators (TEG). A crucial component of a TEG module is the diffusion barrier layer, which prevents the inter-diffusion between the thermoelectric (TE) material and the metal interconnect at the hot junction. Previous reports indicate that elemental nickel is a suitable diffusion-barrier (DB) layer material in Mg2Si. The contact between the DB layer and the TE material is usually made using the monoblock sintering technique, which is a single-step compaction cum contacting method. Monoblock sintering of Ni/Mg2Si has been reported with the compaction carried out using a current assisted hot-pressing technique. Alternatively, induction assisted hot-pressing can be a low-cost, scalable alterative for monoblock sintering of Ni/Mg2Si. Bi doped Mg2Si was synthesized using induction melting of the constituent elements in an inert argon atmosphere. The obtained ingot was hand crushed and the TE powder sandwiched between nickel foils. The compacting was carried out in an induction assisted hot-uniaxial press. The contact interface was probed using scanning electron microscopy (SEM) along with energy dispersive x-ray spectroscopy. SEM images indicate good adhesion along with the formation of an intermediate layer between nickel and Mg2Si with distinct phases of Ni-Si-Mg combinations. Integral contact resistance measurements indicate an Ohmic contact with excellent contact resistance (rc) value of ∼ 14 μΩ cm2.

Similar content being viewed by others

References

R. Bjørk, J. Electron. Mater. 45, 1301 (2016).

X.R. Ferreres, S. Aminorroaya-Yamini, M. Nancarrow, and C. Zhang, Mater. Des. 107, 90 (2016).

A. Singh, S. Bhattacharya, C. Thinaharan, D.K. Aswal, S.K. Gupta, J.V. Yakhmi, and K. Bhanumurthy, J. Phys. D: Appl. Phys. 42, 015502 (2009).

T. Sakamoto, T. Iida, Y. Honda, M. Tada, T. Sekiguchi, K. Nishio, Y. Kogo, and Y. Takanashi, J. Electron. Mater. 41, 1805 (2012).

P. Gao, I. Berkun, R.D. Schmidt, M.F. Luzenski, X. Lu, P. Bordon-Sarac, E.D. Case, and T.P. Hogan, J. Electron. Mater. 43, 1790 (2014).

S. Battiston, S. Fiameni, M. Saleemi, S. Boldrini, A. Famengo, F. Agresti, M. Stingaciu, M.S. Toprak, M. Fabrizio, and S. Barison, J. Electron. Mater. 42, 1956 (2012).

J. de Boor, C. Gloanec, H. Kolb, R. Sottong, P. Ziolkowski, and E. Müller, J. Alloys Compd. 632, 348 (2015).

T. Sakamoto, Y. Taguchi, T. Kutsuwa, K. Ichimi, S. Kasatani, and M. Inada, J. Electron. Mater. 45, 1321 (2016).

A. Ferrario, S. Battiston, S. Boldrini, T. Sakamoto, E. Miorin, A. Famengo, A. Miozzo, S. Fiameni, T. Iida, and M. Fabriozo, Mater. Today Proc. 2, 573 (2015).

J. de Boor, D. Droste, C. Schneider, J. Janek, and E. Mueller, J. Electron. Mater. 45, 5313 (2016).

T. Sakamoto, K. Sugiyama, D. Mori, M. Ogi, K. Nishio, Y. Kogo, Y. Takanashi, and T. Iida, AIP Conf. Proc. 1449, 223 (2012).

J. de Boor, T. Dasgupta, H. Kolb, C. Compere, K. Klem, and E. Mueller, Acta Mater. 77, 68 (2014).

Y. Mito, A. Ogino, S. Konno, and H. Udono, J. Electron. Mater. 46, 3103 (2017).

A.D. LaLonde, T. Ikeda, and G.J. Snyder, Rev. Sci. Instrum. 82, 025104 (2011).

Y.K. Song and R.A. Varin, Metall. Mater. Trans. A 32, 5 (2001).

Acknowledgments

KM would like to acknowledge G. K. Goyal for assistance regarding the uniaxial hot-pressing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mitra, K., Mahapatra, S. & Dasgupta, T. Fabrication of Nickel Contacts for Mg2Si Based Thermoelectric Generators via an Induction Assisted Rapid Monoblock Sintering Technique. J. Electron. Mater. 48, 1754–1757 (2019). https://doi.org/10.1007/s11664-018-06889-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-06889-7