Abstract

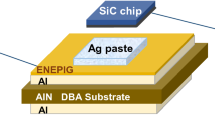

We studied the thermal fatigue behavior of submicron silicon carbide particle (SiCp)-doped silver (Ag) microflake sinter joints for die attachment in next-generation power devices. Si dummy chips and direct bonded copper substrates with various metallization schemes were bonded using SiCp-doped Ag microflakes under mild conditions (250°C, 30 min, 0.4 MPa). The SiCp was distributed homogeneously in the porous Ag network and inhibited morphological evolution during thermal cycling tests. The shear strength of as-sintered pure Ag and SiCp-added joints was ∼50 MPa and 35 MPa, respectively. Thermal cycling tests from −40°C to 250°C were conducted for up to 1000 cycles (hours) to characterize the thermostability of the bonded joints. After 1000 cycles, joints with and without SiCp experienced bonding degradation, with shear strength of ∼25 MPa and 20 MPa, respectively. Thus, after 1000 cycles, the shear strength of pure Ag and SiCp-doped joints decreased by 58% and 42%, respectively, compared with their maximum value. Coarsening of porous Ag occurred in pure Ag joints. SiCp addition inhibited morphological evolution of SiCp-doped joints during thermal cycling. However, vertical cracks generated by thermal stress were observed in joints both with and without SiCp, which may limit long-term reliability.

Similar content being viewed by others

References

J. Millan, P. Godignon, X. Perpina, A. Perez-Tomas, and J. Rebollo, IEEE Trans. Power Electron. 29, 2155 (2014).

T. Kunimune, M. Kuramoto, S. Ogawa, T. Sugahara, S. Nagao, and K. Suganuma, Acta Mater. 89, 133 (2015).

H. Chin, K. Cheong, and A. Ismail, Metall. Mater. Trans. B 41, 824 (2010).

Y. Gao, A. Huang, S. Krishnaswami, J. Richmond, and A. Agarwal, IEEE Trans. Ind. Appl. 44, 887 (2008).

J. Biela, M. Schweizer, S. Waffler, and J. Kolar, IEEE Trans. Ind. Electron. 58, 2872 (2011).

R. Johnson, C. Wang, Y. Liu, and J. Scofield, IEEE Trans. Electron. Packag. Manuf. 30, 182 (2007).

P. Ning, T. Lei, F. Wang, G.Q. Lu, K. Ngo, and K. Rajashekara, IEEE Trans. Power Electron. 25, 2059 (2010).

A.A. Bajwa, Y. Qin, R. Reiner, R. Quay, and J. Wilde, IEEE Trans. Compon. Packag. Manuf. Technol. 5, 1402 (2015).

J. Sopousek, J. Bursik, J. Zalesak, and Z. Pesina, J. Min. Metall. B 48, 63 (2012).

H. Yu, L. Li, and Y. Zhang, Scr. Mater. 66, 931 (2012).

H. Alarifi, A. Hu, M. Yavuz, and Y. Zhou, J. Electron. Mater. 40, 1394 (2011).

P. Peng, A. Hu, A. Gerlich, G. Zou, L. Liu, Y. Zhou, and A.C.S. Appl, Mater. Interface 7, 12597 (2015).

J. Yoo, D. Han, S.B. Park, J. Chae, J. Kim, and J. Kwak, Nanotechnology 25, 465706 (2014).

Q. Huang, W. Shen, Q. Xu, R. Tan, and W. Song, Mater. Chem. Phys. 147, 550 (2014).

J. Jiu, H. Zhang, S. Koga, S. Nagao, Y. Izumi, and K. Suganuma, J. Mater. Sci.: Mater. Electron. 26, 7183 (2015).

R. Khazaka, L. Mendizabal, and D. Henry, J. Electron. Mater. 43, 2459 (2014).

K. Siow, J. Electron. Mater. 43, 947 (2014).

S. Sakamoto, T. Sugahara, and K. Suganuma, J. Mater. Sci.: Mater. Electron. 24, 1332 (2012).

S. Sakamoto, S. Nagao, and K. Suganuma, J. Mater. Sci.: Mater. Electron. 24, 2593 (2013).

H. Zhang, S. Nagao, and K. Suganuma, J. Electron. Mater. 44, 3896 (2015).

H. Zhang, S. Nagao, K. Suganuma, H.-J. Albrecht, and K. Wilke, J. Mater. Sci.: Mater. Electron. 27, 1337 (2015).

J.F. Rohan, G. O’Riordan, and J. Boardman, Appl. Surf. Sci. 185, 289 (2002).

B. Lee, H. Jeon, K.-W. Kwon, and H.-J. Lee, Acta Mater. 61, 6736 (2013).

Acknowledgements

The present study was partially supported by the Japan Society for the Promotion of Science (Grant-in-Aid for Scientific Research No. 24226017).

Conflict of Interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Fig. S1

EDS elemental mapping of SiCp-doped joints on (a) Ag100, (b) Ti500, and (c) Ni5000 substrates after 500 cycles (JPEG 4307 kb)

Fig. S2

Optical microscopy and scanning electron microscopy images of fracture surfaces of (a) pure Ag joints on Ag100 substrate before cycling, (c) pure Ag joints on Ag100 substrate after 1000 cycles, (e) SiCp-doped joints on Ag100 substrate before cycling, and (g) SiCp-doped joints on Ag100 substrate after 1000 cycles. (b, d, f, h–k) Magnified views of areas indicated by white rectangles (JPEG 3779 kb)

Rights and permissions

About this article

Cite this article

Zhang, H., Chen, C., Nagao, S. et al. Thermal Fatigue Behavior of Silicon-Carbide-Doped Silver Microflake Sinter Joints for Die Attachment in Silicon/Silicon Carbide Power Devices. J. Electron. Mater. 46, 1055–1060 (2017). https://doi.org/10.1007/s11664-016-5069-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-5069-1